Simple-structure exhaust air waste heat recovery energy-saving device

A waste heat recovery technology with a simple structure, applied in heat recovery systems, energy recovery systems for ventilation and heating, energy-saving heating/cooling, etc., can solve air resistance, increased fan energy consumption, decreased heat exchange efficiency, and high prices problems, to achieve the effect of reducing heat transfer, reducing cold/heat load, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

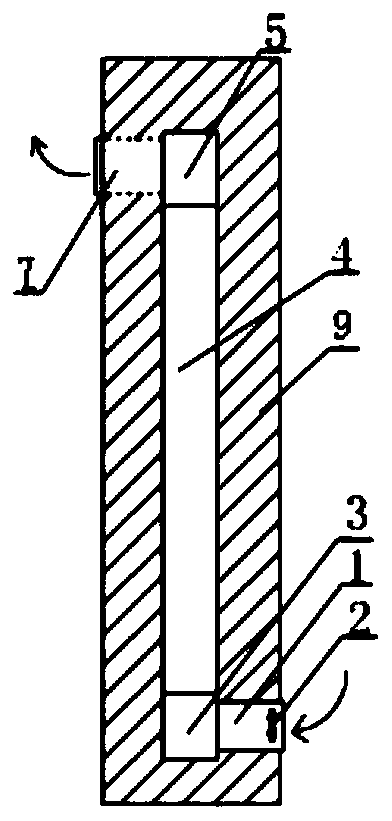

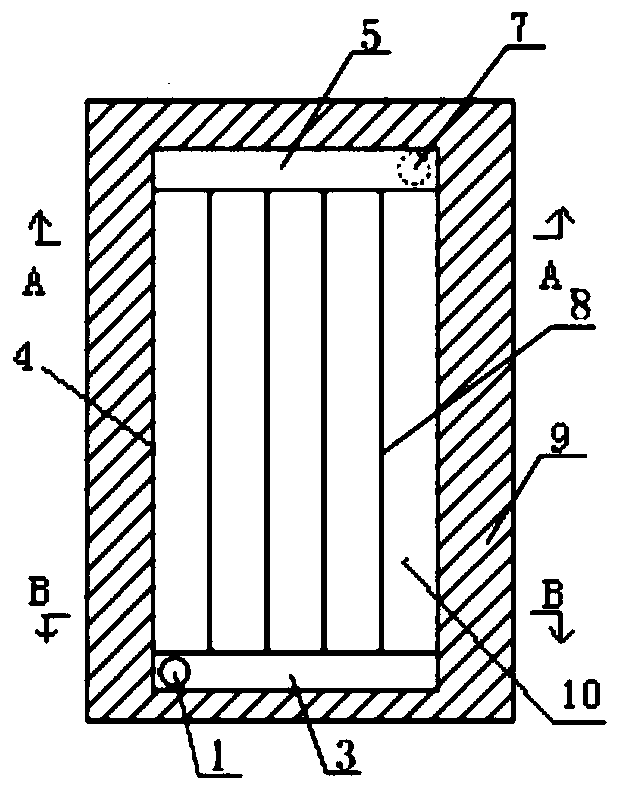

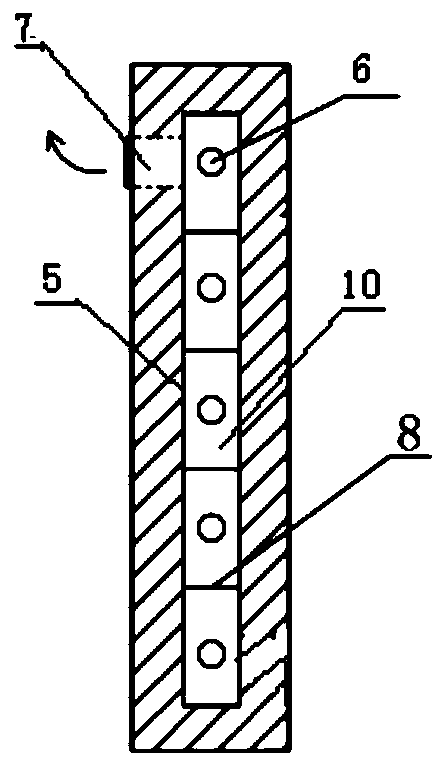

[0017] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention is an energy saving device with simple structure for recovery of exhaust heat, comprising an exhaust inlet 1, an exhaust fan 2, an exhaust splitter box 3, an exhaust flow channel 4, an exhaust collector box 5, several orifices 6, exhaust The air outlet 7 and the door body 9, the door body 9 is provided with an exhaust air distribution box 3, an exhaust air flow channel 4 and an exhaust air collecting box 5, and the two ends of the exhaust air flow channel 4 are respectively provided with an exhaust air distribution box 3 and the exhaust air collecting box 5, and the upper side wall of the exhaust air collecting box 3 and the lower side wall of the exhaust air collecting box 5 are provided with a number of orifices 6, the exhaust air dividing box 3 and the exhaust air The collecting boxes 5 are all communicated with the exhaust flow channel 4 through the orifice 6, and the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com