A water quality decision-making method for oilfield injection in high water-cut period based on water quality sensitivity

A technology of high water cut, oilfield water injection, applied in earthwork drilling, data processing applications, wellbore/well components, etc., can solve the problems of unclear change laws, no clear decision-making water injection water quality technical policy boundaries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

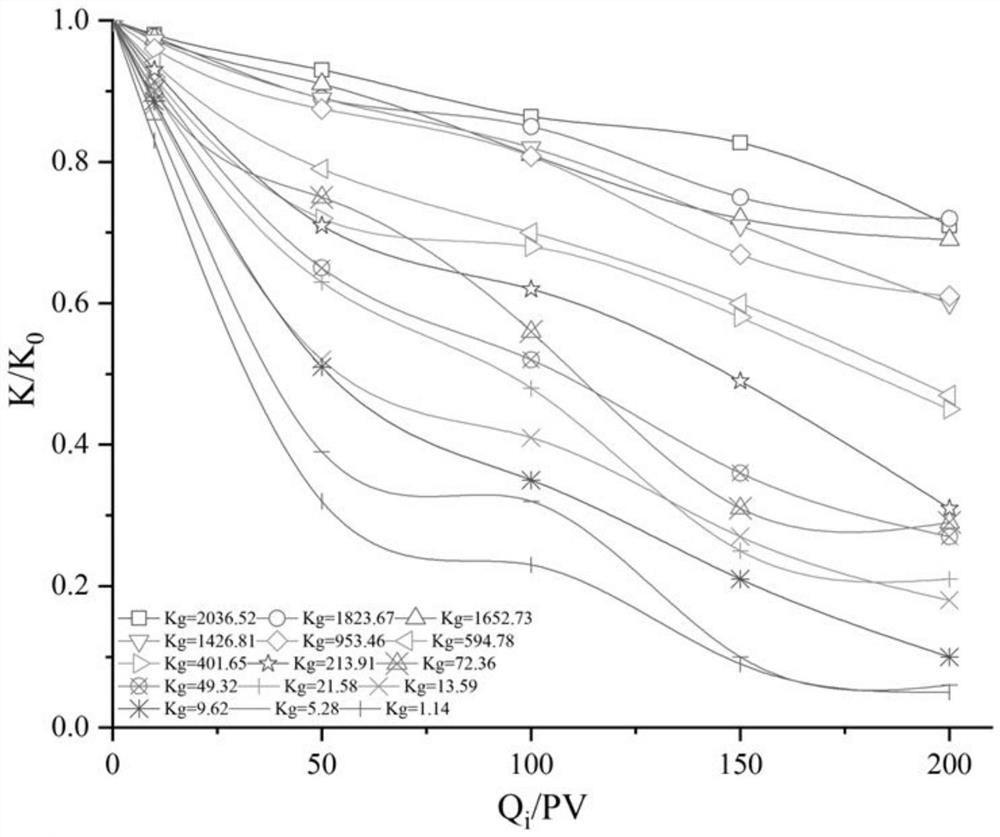

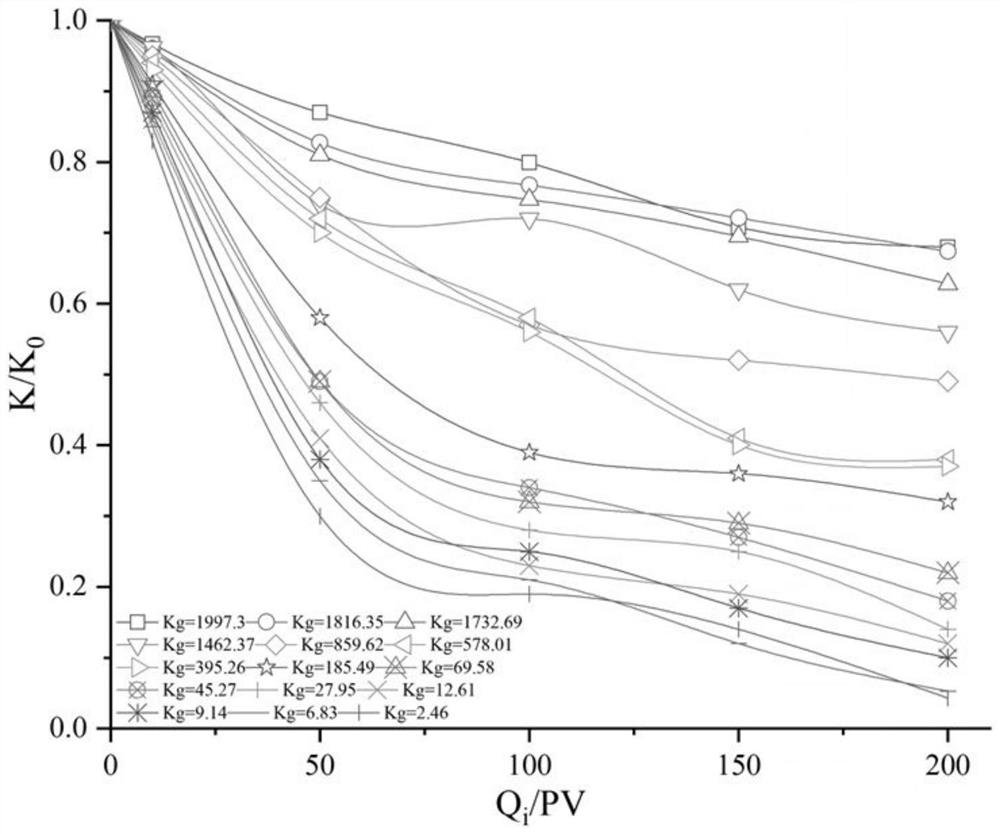

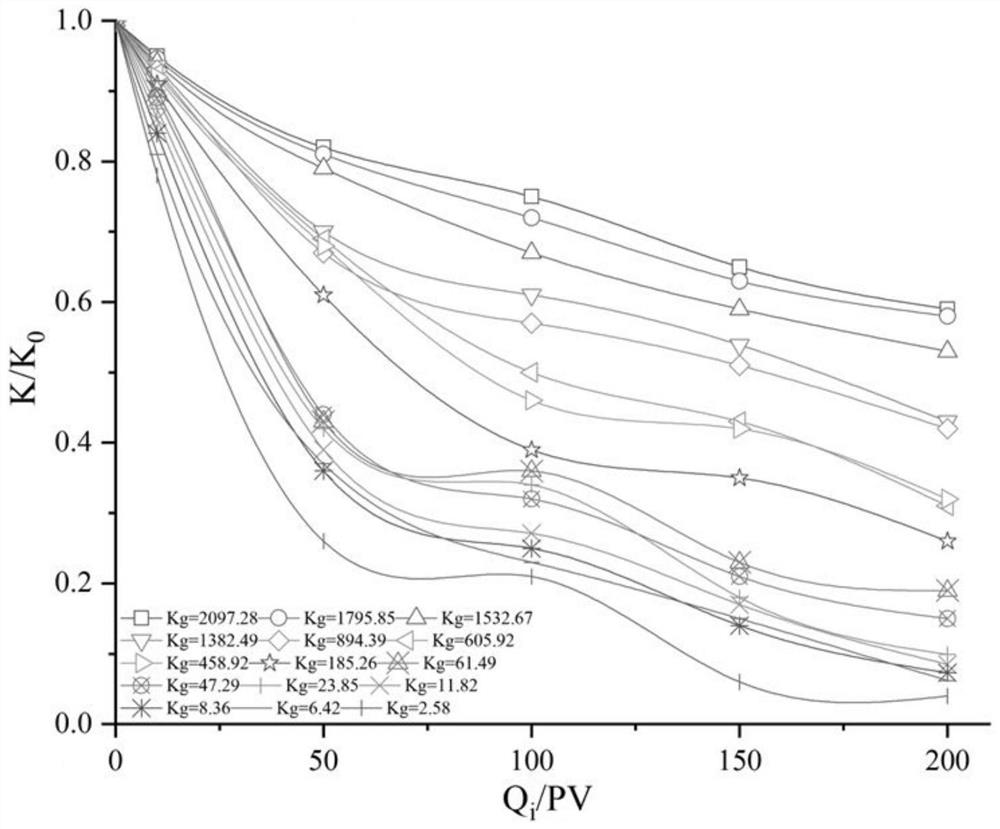

Image

Examples

Embodiment 1

[0065] A water quality decision-making method for oilfield water injection in high water-cut periods based on water quality sensitivity. The specific implementation needs to know the geological situation of the block where the water injection system is located, including: well spacing, row spacing, cumulative water injection volume and For injection volume, and control of reservoir thickness, porosity and permeability, the Lai 38 fault block in Guangli Oilfield is selected for analysis, including the following steps:

[0066] (1) Calculate the pore volume V of the controlled reservoir of each well φi ; Suppose the controlled oil supply area of a single well is F=well spacing×row spacing, the unit is m 2 , the total number of wells in the water injection system is N, then:

[0067] V φi =Fhφ(I)

[0068] In the formula (I), h is the effective thickness of the oil layer, m;

[0069] φ is the average effective porosity;

[0070] i is the label of the water injection well, i...

Embodiment 2

[0123] According to the water quality sensitivity decision-making method for oilfield water injection in high water cut period described in Example 1, the difference is:

[0124] Select Xing3-4 area of Xingshugang Oilfield for analysis, the average permeability of formation before water injection development is 900.3×10 -3 μm 2 According to Table 2, it can be seen that the water quality of the injection water is Grade IV. Calculated from steps (1) to (4), the current average permeability of the formation is 300.7×10 -3 μm 2 , the water quality standard number is 7.2, according to Table 3, it can be seen that the optimal water quality for water injection development should be Grade III water quality. The field test of improving the water quality from grade IV to grade III shows that the oil recovery rate of this block is increased by 6.3%, which shows that the water quality determined by this water injection quality decision method is correct.

Embodiment 3

[0126]According to the water quality sensitivity decision-making method for oilfield water injection in high water cut period described in Example 1, the difference is:

[0127] Selecting the South 1 area of Sartu Oilfield for analysis, the average permeability of the formation before water injection development was 1646.1×10 -3 μm 2 , according to Table 2, we can see that the current water quality of injection water is V-level water quality. Calculated from steps (1) to (4), the current average permeability of the formation is 943.6×10 -3 μm 2 , the water quality standard number is 7.1, according to Table 3, it can be seen that the optimal water quality for water injection development should be grade IV water quality. The field test of improving the water quality from grade V to grade IV shows that the oil recovery rate of this block has increased by 8.2%, which shows that the water quality determined by this water injection quality decision method is correct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com