Cold-bending thin-walled steel lattice column composite wall with built-in straw grass brick

A technology for cold-formed thin-walled steel and composite walls, which is applied to walls, building components, building types, etc. problems such as low pressure bearing capacity, to achieve the effect of convenient production and processing, environmental protection, and promotion of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

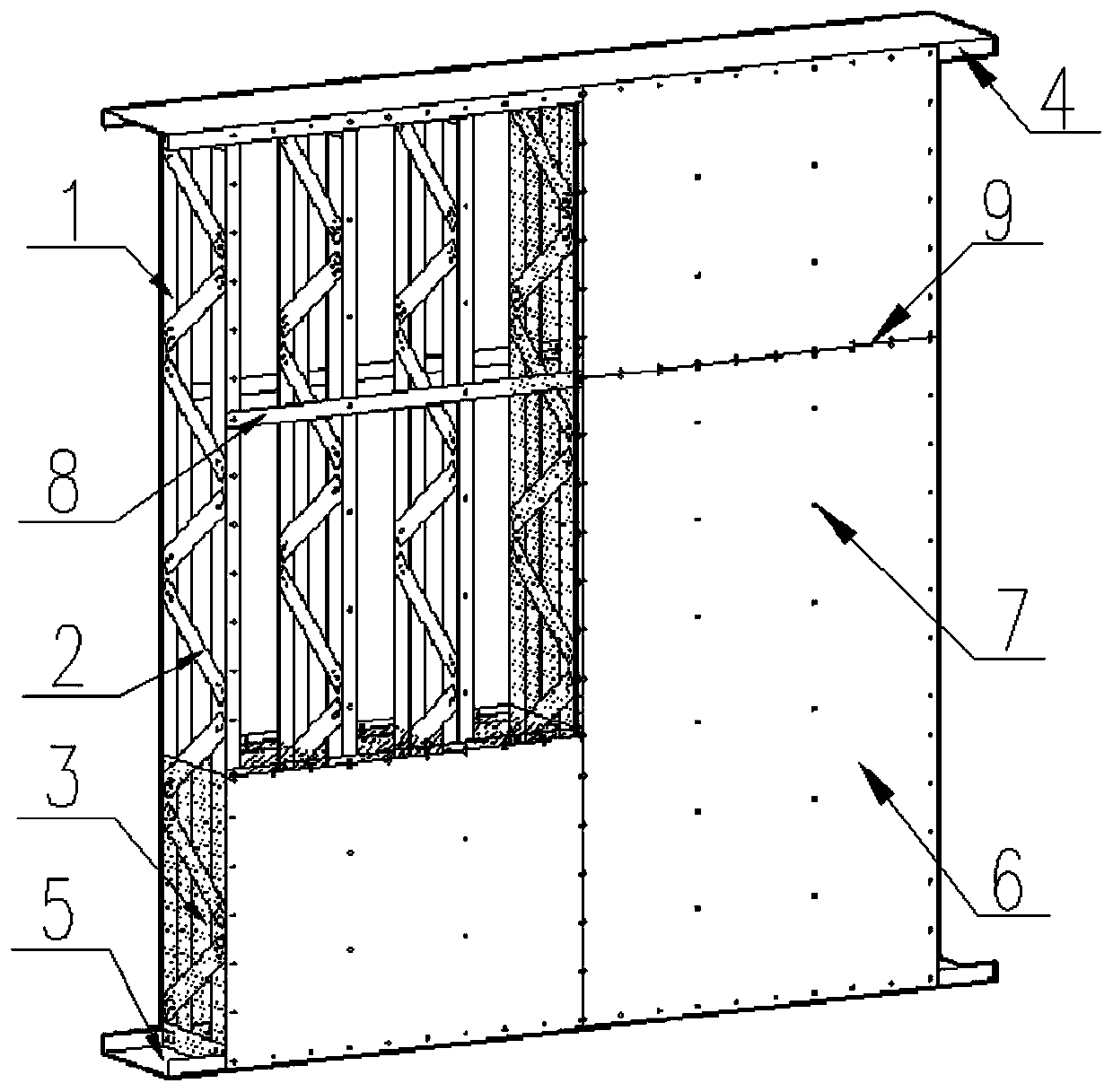

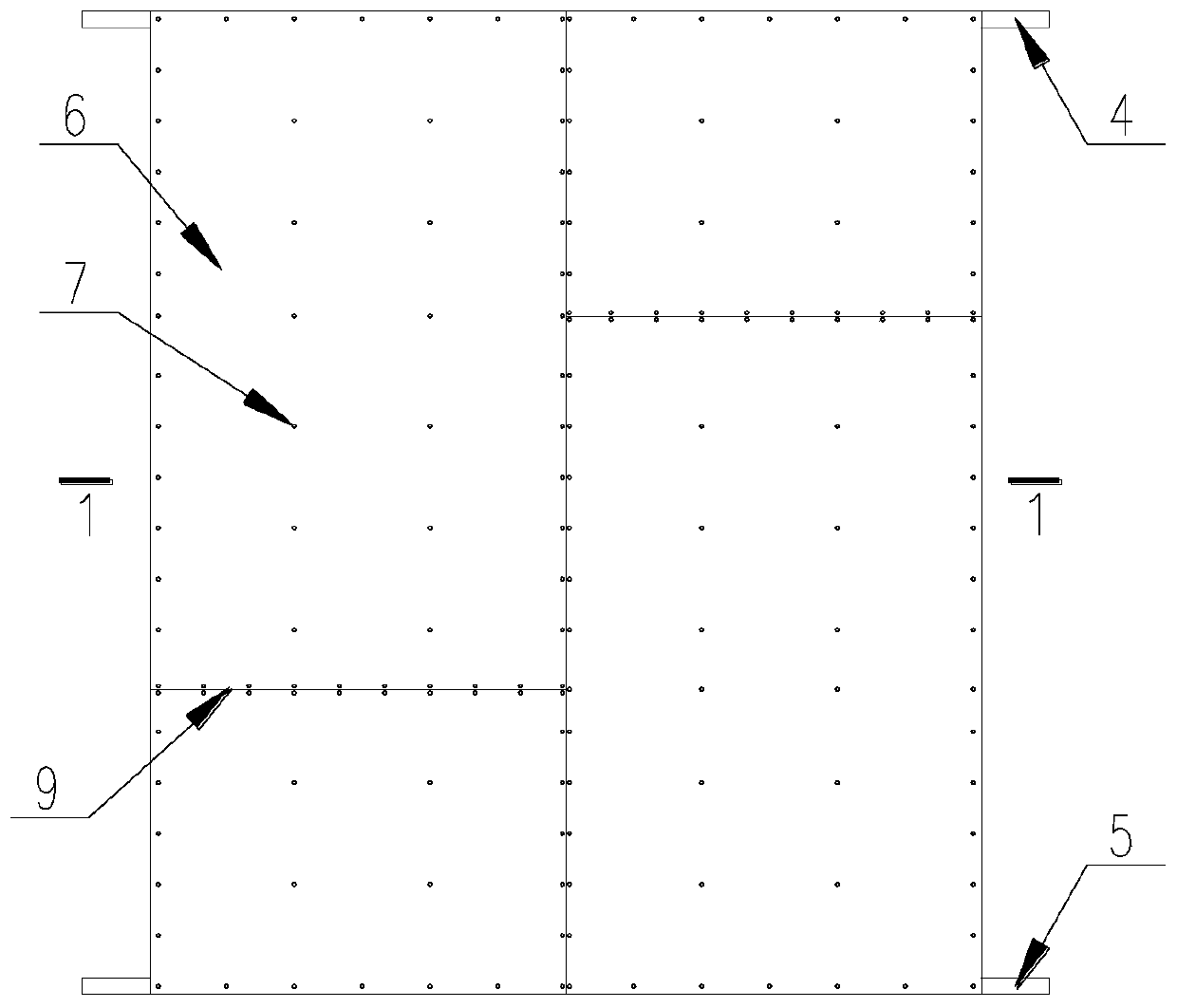

[0022] see Figure 1 to Figure 5 , a composite wall with built-in straw straw brick cold-formed thin-walled steel lattice columns, including a composite wall skeleton formed by cold-formed thin-walled steel lattice columns, top guide rails 4 and bottom guide rails 5, in the composite wall Straw grass bricks 3 are filled and stacked in the skeleton, and cladding panels 7 are fixed on both sides of the composite wall skeleton.

[0023] The cold-formed thin-walled steel lattice column column 1 and the cold-formed thin-walled steel lattice column trim 2 are connected by self-tapping screws 7 to form a cold-formed thin-walled steel lattice column. The trims of the column limbs should be located on the same plane. The thickness of the panel should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com