System and method for preparing bio-oil rich in levoglucosan

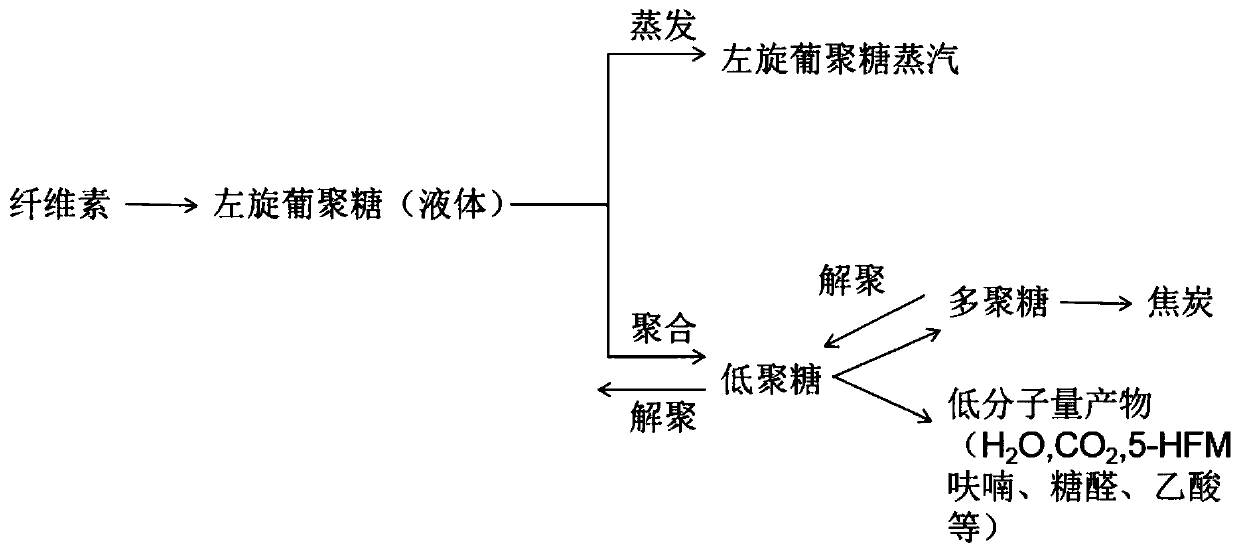

A levoglucosan and preparation system technology, applied in the field of biomass pyrolysis, can solve the problems of low content of levoglucosan in bio-oil, high energy consumption, loss of use value, etc., and achieve high output, fast heating rate, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The selected raw material is cellulose with a particle size of 25 microns. The heliostat field is composed of 24 flat glass mirrors of 30×38 cm. The diameter of the hyperboloid mirror is 1.5 m. The capacity of the screw feeder is about 50 g. The feeding speed is 1g / min. The solar fluidized bed pyrolysis reactor adopts a cylinder with an inner diameter of 22mm made of Amersil TO8 quartz tube, a wall thickness of 1.5mm, a capillary with a diameter of 1mm, and a branch at 24cm above it. The incident radiation flux per unit area ranges from 180-220W / cm 2 The reaction occurred, and several sets of experiments were carried out separately. The primary tar gas produced by pyrolysis was condensed and collected by the bio-oil classification condensation collection device. gas.

[0048] Table 1 Levoglucosan yield results

[0049] Incident radiant flux per unit area

[0050] According to the above data, considering economic factors, at 200W / cm 2 It is the most economic...

Embodiment 2

[0052] The incident radiation flux per unit area is 200W / cm 2 Under the same conditions, experiments were carried out with multiple groups of different feeding speeds: 0.2g / min, 0.5g / min, 1g / min, 1.5g / min, 2g / min, and the rest of the conditions were the same

[0053] Example 1, the yield of levoglucosan is shown in Table 2.

[0054] Table 2 Levoglucosan yield results

[0055] Feeding speed

Levoglucosan yield.

0.2g / min

29.8%

0.5g / min

30.6%

1g / min

31.2%

1.5g / min

29.2%

2g / min

27.8%

[0056] According to the above data, the incident radiation flux per unit area is 200W / cm 2 When the feed rate is 1g / min under the condition of , the yield of levoglucosan reaches 31.2%.

[0057] To sum up, the present invention utilizes the dual-temperature zone effect of concentrating solar energy, so that the pyrolysis product of cellulose, the primary tar, is immediately transferred from the high-temperature zone of the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com