Ultra-wide white fluorescent material, preparation method and application of ultra-wide white fluorescent material and lighting appliance

A technology for fluorescent materials and lighting appliances, applied in the field of fluorescent materials, can solve the problems of excitation and emission spectra, inconsistent light decay and efficiency, reabsorption of three-color fluorescent materials, affecting luminous efficiency, etc., and achieves good spectral controllability and synthesis. The effect of high temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

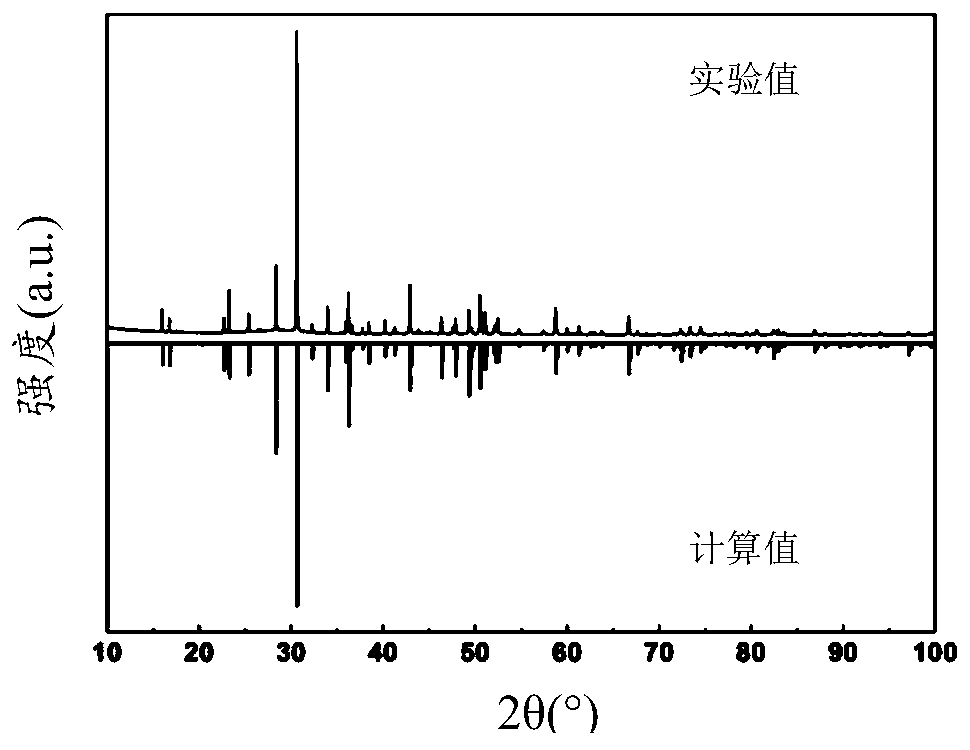

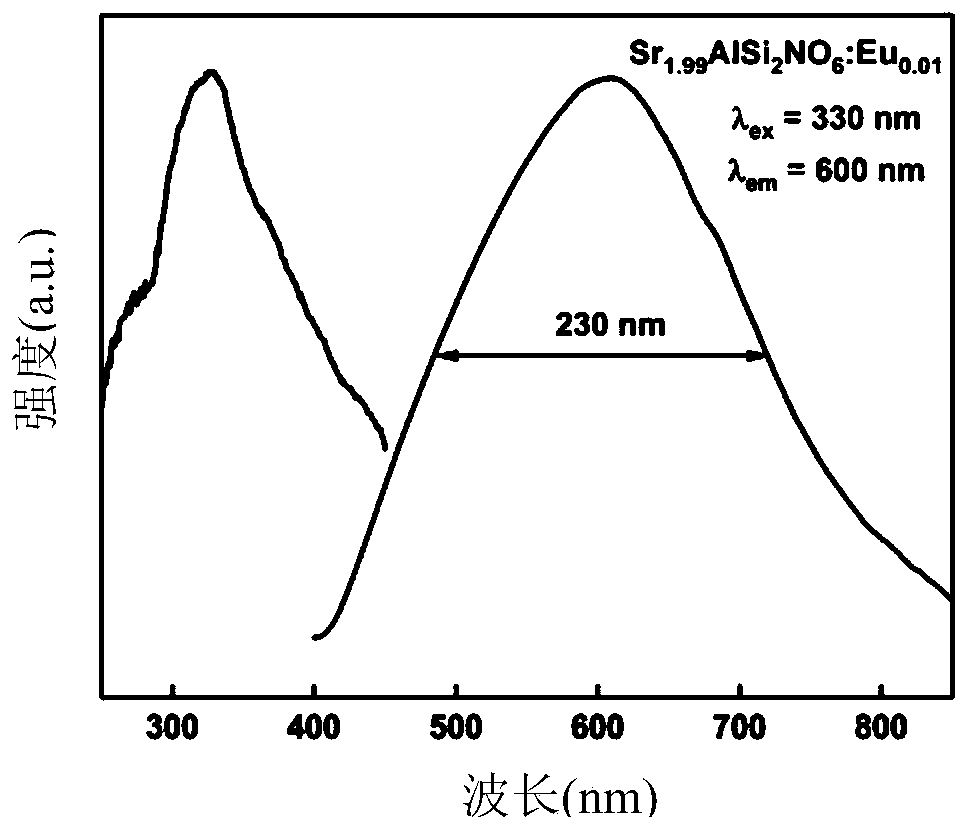

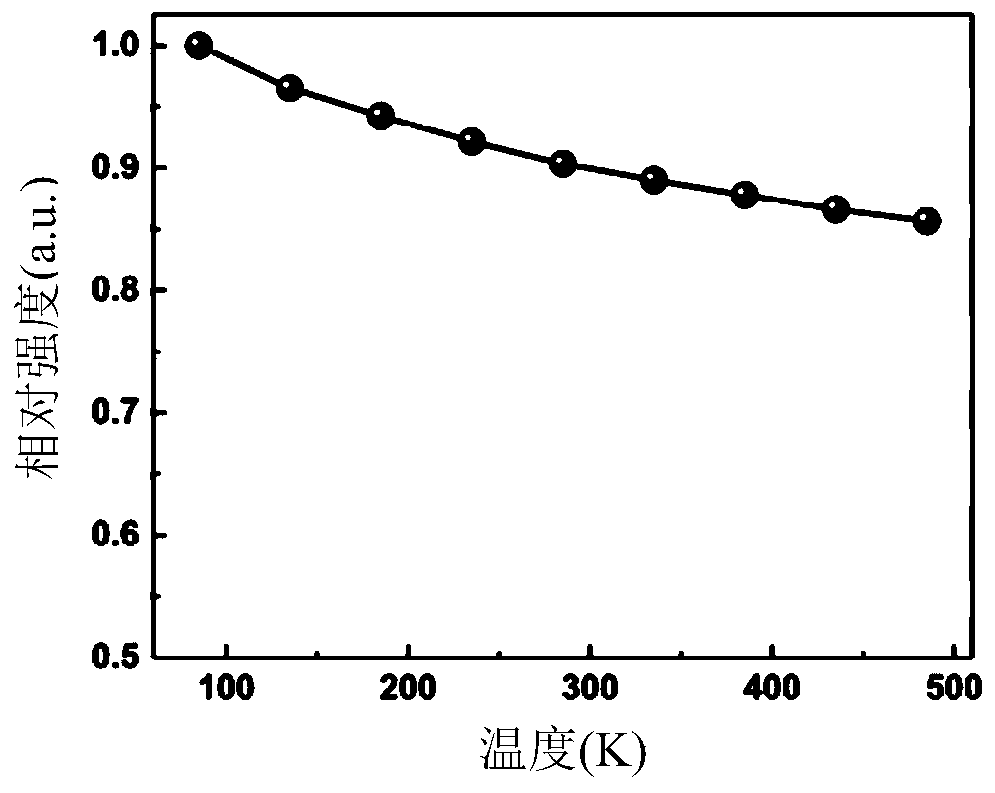

[0034] Embodiment 1~3 provides a kind of Eu 2+ The preparation method of the activated single matrix white light fluorescent material, its chemical formula is Sr 2-x-y-a Ca x Ba y Al 1+z Si 2-z N 1-z o 6+z :Eu a , where, x=y=0, z=0~1, a=0.01, namely Sr 1.99 AlSi 2 NO 6 :Eu 0.01 (denoted as T1), Sr 1.99 Al 1.5 Si 1.5 N 0.5 o 6.5 :Eu 0.01 (denoted as T2), Sr 1.99 Al 2 SiO 7 :Eu 0.01 (marked as T3), the specific preparation process is as follows:

[0035] Weigh SrCO according to stoichiometric ratio 3 Powder, Si 3 N 4 Powder, SiO 2 Powder, Al 2 o 3 Powder and Eu 2 o 3 The powder is used as the starting material, and is sintered at 1380°C for 4 hours in a nitrogen-hydrogen mixed atmosphere; the sintered fluorescent material is kept at 1300°C and 0.9MPa nitrogen atmosphere for 4 hours, cooled, and the sample is taken out of the furnace , ground and crushed to obtain the Eu 2+ The activated single-matrix white light fluorescent materials T1-T3 are subje...

Embodiment 4~9

[0043] Embodiment 4~9 provides a kind of Eu 2+ The preparation method of the activated single matrix white light fluorescent material, its chemical formula is Sr 2-x-y-a Ca x Ba y Al 1+z Si 2-z N 1-z o 6+z :Eu a , where, y=z=0, x=0~2, a=0.01, namely Sr 1.74 Ca 0.25 AlSi 2 NO 6 :Eu 0.01 (denoted as T4), Sr 1.49 Ca 0.5 AlSi 2 NO 6 :Eu 0.01 (denoted as T5), Sr 1.24 Ca 0.75 AlSi 2 NO 6 :Eu 0.01 (marked as T6), Sr 0.99 CaAlSi 2 NO 6 :Eu 0.01 (denoted as T7), Sr 0.49 Ca 1.5 AlSi 2 NO 6 :Eu 0.01 (marked as T8), Ca 1.99 AlSi 2 NO 6 :Eu 0.01 (recorded as T9), the specific preparation process is as follows:

[0044] Weigh CaCO according to stoichiometric ratio 3 Powder, SrCO 3 Powder, Si 3 N 4 Powder, SiO 2 Powder, Al 2 o 3 Powder and Eu 2 o 3 The powder is used as the starting material, and is sintered at 1380°C for 4 hours in a nitrogen-hydrogen mixed atmosphere; the sintered fluorescent material is kept at 1300°C and 0.9MPa nitrogen atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com