Thermodegradable polypropylene gradient phase change heat storage material and preparation method thereof

A phase-change heat storage material, polypropylene technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of changing the phase change point, reducing the proportion of sensible heat, low efficiency, etc., to achieve good compatibility performance, reducing thermal insulation cracks, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

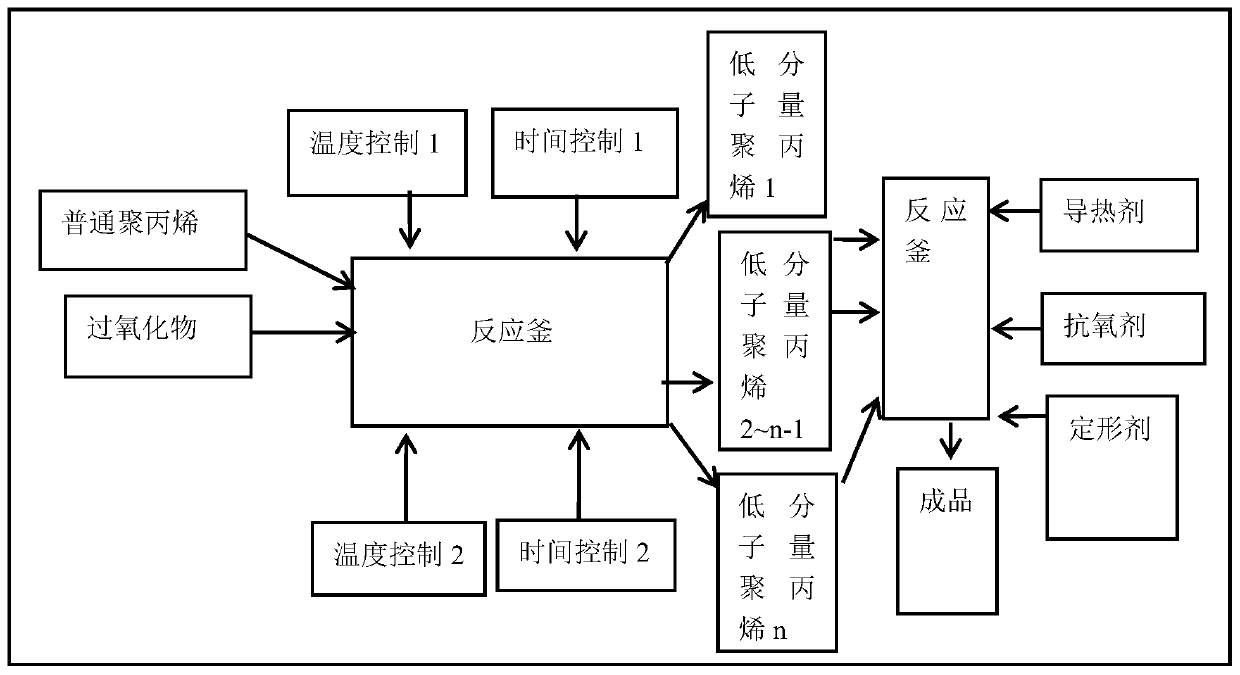

Method used

Image

Examples

Embodiment 1

[0040] 100 kg of polypropylene was added to the reactor, 4 kg of dibenzoyl peroxide was added to the reactor, the temperature was 350° C., and the reaction was sealed and heated for 17 hours to obtain a low molecular weight polypropylene with a molecular weight of 600 and a melting point of 71° C.

[0041] Add 100 kg of polypropylene into the reactor, add 3 kg of dibenzoyl peroxide into the reactor, and heat at 330° C. for 12 hours to obtain a low-molecular-weight polypropylene with a molecular weight of 1500 and a melting point of 88° C.

[0042] 100 kg of polypropylene was added to the reactor, 2 kg of dibenzoyl peroxide was added to the reactor, the temperature was 300 ° C, and the reaction was sealed and heated for 9 hours to obtain low molecular weight polypropylene with a molecular weight of 2500 and a melting point of 104 ° C.

[0043] The low-molecular-weight polypropylene with the above three melting points is composed of a gradient phase-change heat storage material i...

Embodiment 2

[0047] 100 kg of polypropylene was added to the reactor, 4 kg of dibenzoyl peroxide was added to the reactor, the temperature was 350° C., and the reaction was sealed and heated for 15 hours to obtain a low molecular weight polypropylene with a molecular weight of 650 and a melting point of 72° C.

[0048] Add 100 kg of polypropylene into the reactor, add 3 kg of dibenzoyl peroxide into the reactor, and heat at 330° C. for 11 hours to obtain a low molecular weight polypropylene with a molecular weight of 1800 and a melting point of 92° C.

[0049] Add 100 kg of polypropylene into the reactor, add 2 kg of dibenzoyl peroxide to the reactor, and heat at 300° C. for 8 hours to obtain a low molecular weight polypropylene with a molecular weight of 2300 and a melting point of 101° C.

[0050] The above three kinds of low molecular weight polypropylenes with melting points are used in equal proportions to form a gradient phase change heat storage material, add 5% carbon powder, 0.5% p...

Embodiment 3

[0053] 100 kg of polypropylene was added to the reactor, 4 kg of dibenzoyl peroxide was added to the reactor, the temperature was 350° C., and the reaction was sealed and heated for 15 hours to obtain a low molecular weight polypropylene with a molecular weight of 650 and a melting point of 72° C.

[0054] Add 100 kg of polypropylene into the reactor, add 3 kg of dibenzoyl peroxide into the reactor, and heat at 330° C. for 11 hours to obtain a low molecular weight polypropylene with a molecular weight of 1800 and a melting point of 92° C.

[0055] Add 100 kg of polypropylene into the reactor, add 2 kg of dibenzoyl peroxide to the reactor, and heat at 300° C. for 8 hours to obtain a low molecular weight polypropylene with a molecular weight of 2300 and a melting point of 101° C.

[0056] The low-molecular-weight polypropylene with the above three melting points is composed of a gradient phase-change heat storage material at a ratio of 1:2:3, and 8% of graphite powder, 2% of BHA,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com