Preparation method of nano-cellulose-base porous composite material

A technology of nanocellulose and composite materials, which is applied in the field of preparation of nanocellulose-based porous composite materials, can solve problems such as poor biocompatibility, and achieve good biocompatibility and good UV protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

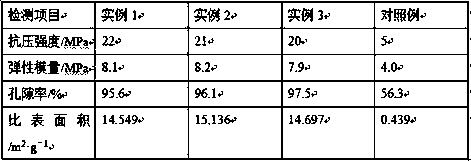

example 1

[0040] Add acetate-esterified nanocellulose, acetic acid, and graphene to the chitosan solution, stir at a high speed of 1500r / min at room temperature for 1 hour, and then ultrasonically disperse for 20 minutes to obtain a mixed dispersion; add agar solution and epichlorohydrin Put the mixed dispersion in the water bath at 80°C and stir for 30 minutes at a speed of 500r / min to obtain the mixed reaction solution; pour the mixed reaction solution into a crystallization dish and freeze it in a freezer for 20 hours to obtain a frozen solid; according to the mass ratio The frozen solid was thawed at 1:50 and then soaked in anhydrous B to solidify for 22 hours to obtain the solidified material; according to the mass ratio of 1:40, the solidified material was soaked in deionized water for 2 days, washed with absolute ethanol three times, and freeze-dried to obtain Nanocellulose-based porous composites. Acetate nanocellulose, acetic acid, graphene, the parts by weight of chitosan solu...

example 2

[0042] Add acetate-esterified nanocellulose, acetic acid, and graphene into the chitosan solution, stir at a high speed of 1750r / min for 1.2h at room temperature, and then ultrasonically disperse for 25min to obtain a mixed dispersion; add agar solution, epichlorohydrin Add it to the mixed dispersion liquid, place it in a water bath at 82°C and stir at a speed of 550r / min for 35 minutes to obtain a mixed reaction liquid; pour the mixed reaction liquid into a crystallization dish, freeze it in a freezer for 22 hours, and obtain a frozen solid; The frozen solid was thawed at a ratio of 1:50 and then soaked in anhydrous B to solidify for 23 hours to obtain a solidified material; the solidified material was soaked in deionized water for 2 days at a mass ratio of 1:40, washed 4 times with absolute ethanol, and freeze-dried. Nanocellulose-based porous composites were obtained. Acetate nanocellulose, acetic acid, graphene, the parts by weight of chitosan solution are 25 parts of acet...

example 3

[0044] Add acetic acid esterified nanocellulose, acetic acid, and graphene into the chitosan solution, stir at a high speed of 2000r / min for 1.5h at room temperature, and then ultrasonically disperse for 30min to obtain a mixed dispersion; add agar solution, epichlorohydrin Add it to the mixed dispersion liquid, place it in a water bath at 85°C and stir at a speed of 600r / min for 40 minutes to obtain a mixed reaction liquid; pour the mixed reaction liquid into a crystallization dish, freeze it in a freezer for 24 hours, and obtain a frozen solid; The frozen solid was thawed at a ratio of 1:50 and then soaked in anhydrous B to solidify for 24 hours to obtain a solidified material; the solidified material was soaked in deionized water for 3 days at a mass ratio of 1:40, washed 5 times with absolute ethanol, and freeze-dried. Nanocellulose-based porous composites were obtained. Acetate nanocellulose, acetic acid, graphene, the parts by weight of chitosan solution are 30 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com