Process and device for treating dimethylformamide production wastewater and recycling substances

A technology for dimethylformamide and waste water production, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of high salt content in waste water, reduce pollution, and facilitate mass production Collect and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

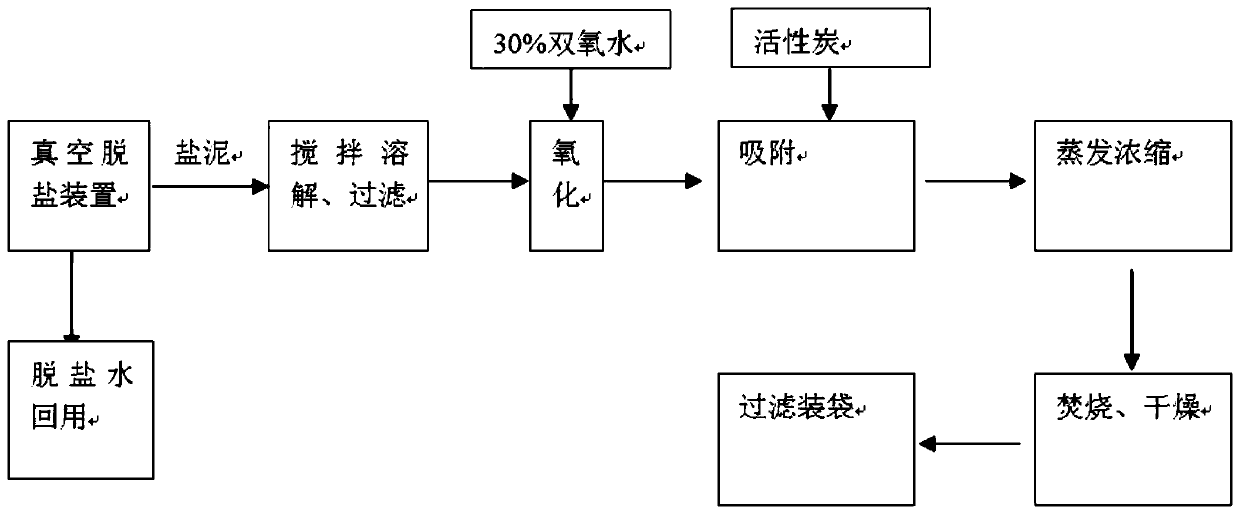

[0047] Embodiment 1 A kind of technology of dimethylformamide production wastewater treatment and material recovery

[0048] The technology of described dimethyl formamide production waste water treatment and material recovery, comprises the following steps:

[0049] Use low-pressure steam to heat and evaporate the high-salt wastewater produced by the preparation of dimethylformamide, and condense the evaporated water vapor to obtain desalted wastewater, which is then recycled; the remaining solid salt mud after evaporation is collected for sodium formate extract.

[0050] The extraction method of sodium formate in the remaining solid salt mud after evaporation is:

[0051] (1) Stir and dissolve the collected solid salt mud to obtain a mixed solution;

[0052] (2) Filter the mixed solution of step (1), and collect the filtrate;

[0053] (3) adding hydrogen peroxide to the filtrate collected in step (2) for oxidation, adding activated carbon after oxidation for adsorption de...

Embodiment 2 2

[0056] Embodiment 2 The device of dimethylformamide production wastewater treatment and material recovery

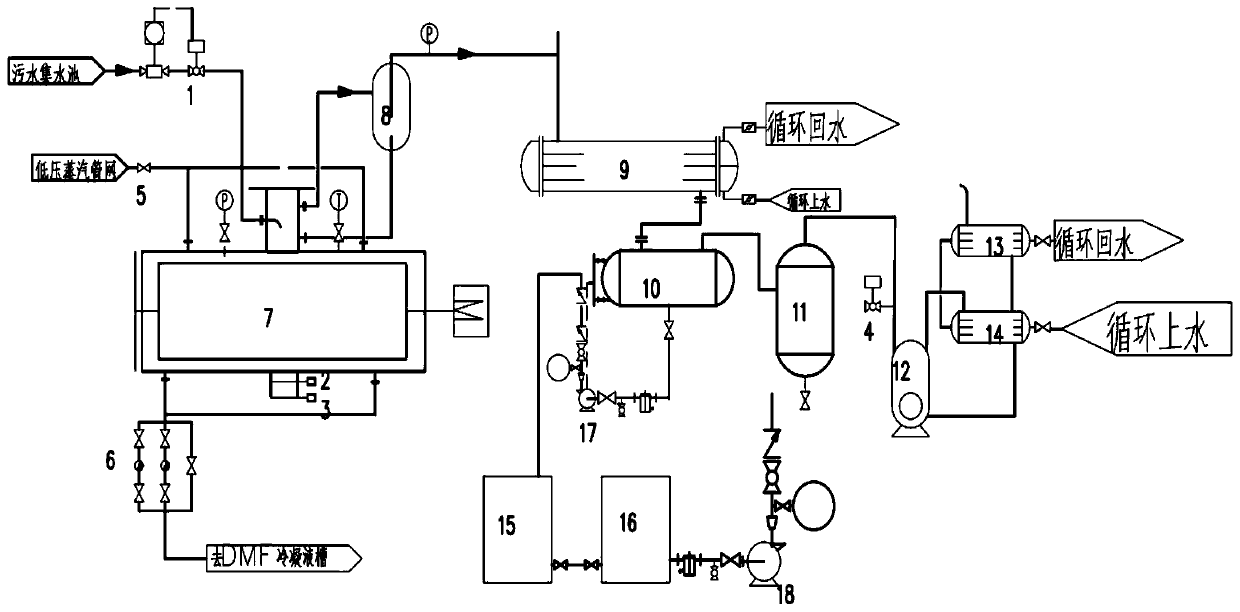

[0057] Such as figure 2 As shown, the high-salt wastewater desalination treatment device includes a vacuum dryer 7, a condenser 9, a first condensation water tank 15, a second condensation water tank 16, a collection water tank 10, a vacuum tank 11, a separation tank 8, a vacuum pump 12, a collection Water pump 17, loading pump 18, first vacuum condenser 13, second vacuum condenser 14, PLC control system and LLC automatic input system.

[0058] The feed port of the vacuum dryer 7 is connected to the sewage collection tank, the outlet is connected to the material inlet of the separation tank 8, the material outlet of the separation tank 8 is connected to the inlet of the condenser 9; the outlet of the condenser 9 is connected to the inlet of the collecting water tank 10 , the collection water tank 10 is connected with the first condensed water tank 15 through the collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com