Cigarette core material capable of being ignited and heated at low temperature to suck and preparation method thereof

A cigarette core and low-temperature technology, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of content disclosure, lack of direct ignition and suction, and uneven heating of the preparation method of low-temperature heating cigarette core materials, so as to improve foreign exchange Effects of income generation, aroma filling, and influence enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

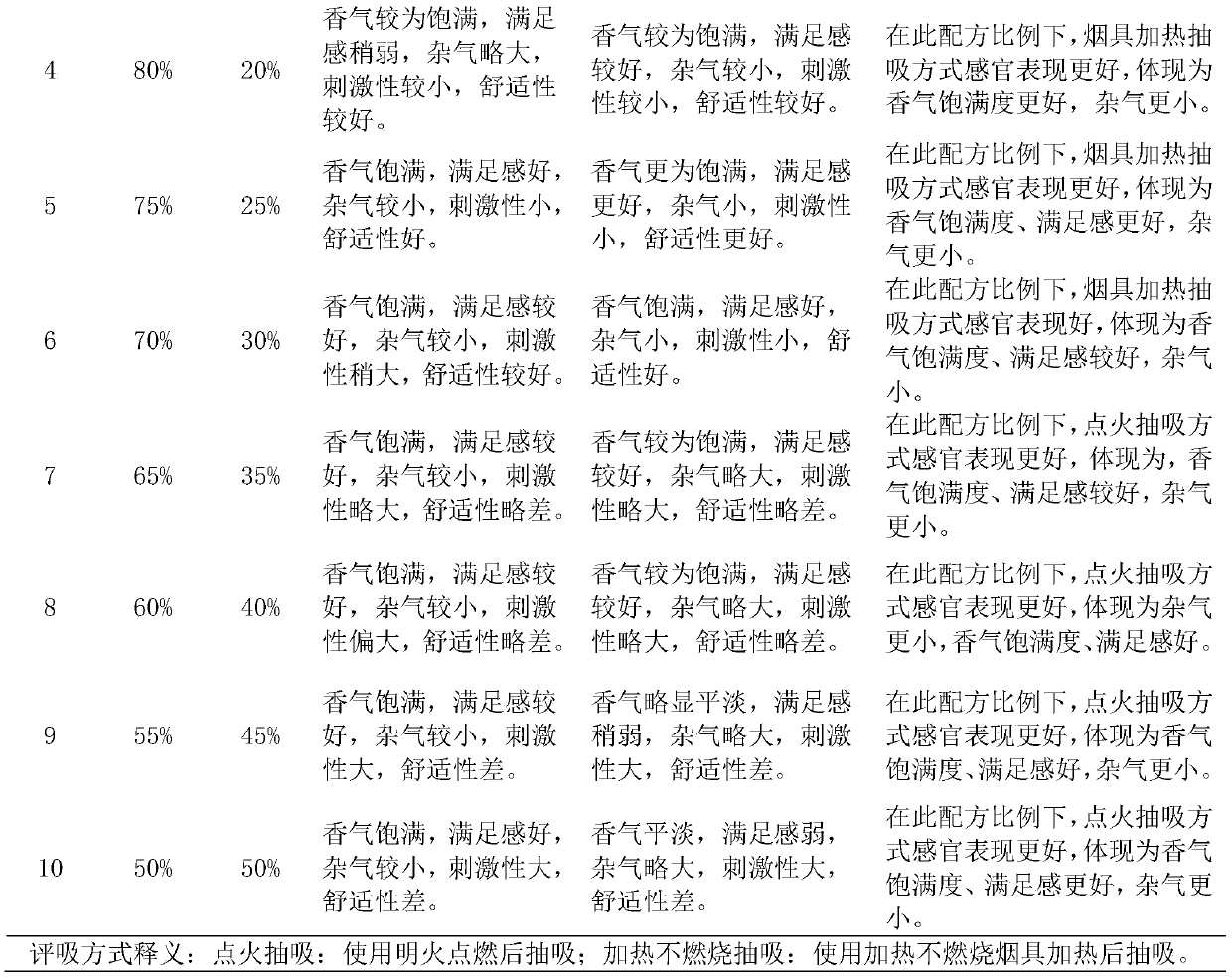

Examples

Embodiment 1

[0025] A cigarette core material that can be ignited and can be heated and smoked at low temperature comprises 75% of shredded flakes and 25% of shredded tobacco by weight percentage. The flake silk comprises 55% of tobacco sheet base, 15% of tobacco refined product, 5% of essence and spices, and 25% of smoking assistant by weight percentage.

[0026] The preparation method of the cigarette core material specifically includes the following steps:

[0027] 1) Preparation of flakes: Tobacco sheet base is made by papermaking method with smoke foam, tobacco stems and tobacco stalks as raw materials; refined tobacco, flavors and fragrances, and smoking additives are mixed in proportion to make a coating liquid, and then the coating The liquid is applied to the base of the tobacco sheet to obtain thin slices, dried and shredded to obtain shredded thin slices, and the shredded width of the thin slices is 0.8mm. The tobacco refined product is preferably a water-soluble extract of tob...

Embodiment 2

[0031] A cigarette core material that can be ignited and can be heated and smoked at low temperature comprises 85% of shredded flakes and 15% of shredded tobacco by weight percentage. The thin sheet comprises 50% of tobacco sheet base, 20% of tobacco refined product, 5% of essence and fragrance, and 25% of smoking assistant by weight percentage.

[0032] The preparation method of the cigarette core material specifically includes the following steps:

[0033] 1) Preparation of flakes: Tobacco sheet base is made by papermaking method with smoke foam, tobacco stems and tobacco stalks as raw materials; refined tobacco, flavors and fragrances, and smoking additives are mixed in proportion to make a coating liquid, and then the coating The liquid is applied to the base of the tobacco sheet to obtain thin slices, dried and shredded to obtain thin slices, and the cut width of the thin slices is 0.7mm. The tobacco refined product is preferably a water-soluble extract of tobacco, the f...

Embodiment 3

[0037] A cigarette core material that can be ignited and can be heated and smoked at low temperature comprises 70% of shredded flakes and 30% of shredded tobacco by weight percentage. The thin sheet comprises 50% of tobacco sheet base, 18% of tobacco refined product, 5% of essence and fragrance, and 27% of smoking assistant in terms of weight percentage.

[0038] The preparation method of the cigarette core material specifically includes the following steps:

[0039] 1) Preparation of flakes: Tobacco sheet base is made by papermaking method with smoke foam, tobacco stems and tobacco stalks as raw materials; refined tobacco, flavors and fragrances, and smoking additives are mixed in proportion to make a coating liquid, and then the coating The liquid is applied to the tobacco sheet base to obtain thin slices, dried and shredded to obtain flakes, and the shredded width of the thin slices is 1.2 mm. The tobacco refined product is preferably a water-soluble extract of tobacco, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com