Carbon-coated aluminum foil for lithium ion batteries

A lithium-ion battery, carbon coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of reducing the bonding strength of the coating and aluminum foil and the stability of the current collector, unfavorable heat dissipation of the battery, difficult to coat uniformly, etc. problems, to achieve the effect of reducing surface free energy, high dispersion stability, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

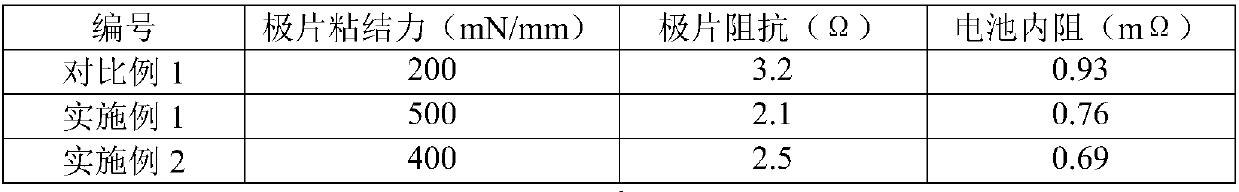

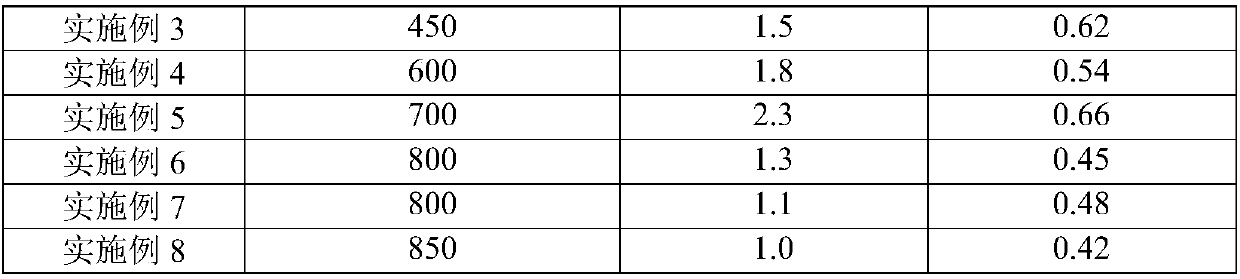

Examples

Embodiment 1

[0037] The conductive agent, binder, solvent and dispersant are: graphene 5%, carbon nanotube 5%, layered conductive graphite 30%, polyacrylate 7%, epoxy resin 5%, water 47% according to mass percentage , HPA 1%, mixed, stirred evenly, printed on aluminum foil by anilox roller, dried at 60°C to obtain carbon-coated aluminum foil with a carbon-coated layer thickness of 1-3 μm on one side.

Embodiment 2

[0039] The conductive agent, binder, solvent and dispersant are: 18% graphene, 8% carbon nanotube, 4% layered conductive graphite, 10% carbon black, 7% acrylate, 7% polyurethane, water 45% and 1% polyvinylpyrrolidone are mixed, stirred evenly, printed on aluminum foil by anilox roller, dried at 60°C to obtain carbon-coated aluminum foil with a carbon-coated layer thickness of 1-3 μm on one side.

Embodiment 3

[0041] The conductive agent, binder, solvent and dispersant are: graphene 5%, carbon nanotube 5%, layered conductive graphite 5%, carbon black 5%, styrene-butadiene rubber 7%, carboxymethyl fiber according to mass percentage Mix 8% plain sodium, 50% water, 10% absolute ethanol, and 5% HPA, mix evenly, print on aluminum foil by anilox roller, dry at 60°C to obtain carbon-coated aluminum foil with a thickness of 1-3 μm on one side of the carbon-coated layer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com