Electromechanical equipment lean design method based on digital twin

A design method and lean technology, applied in electrical digital data processing, computing, special data processing applications, etc., can solve problems such as model inaccuracy, and achieve the effect of ensuring accuracy, data accuracy, and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

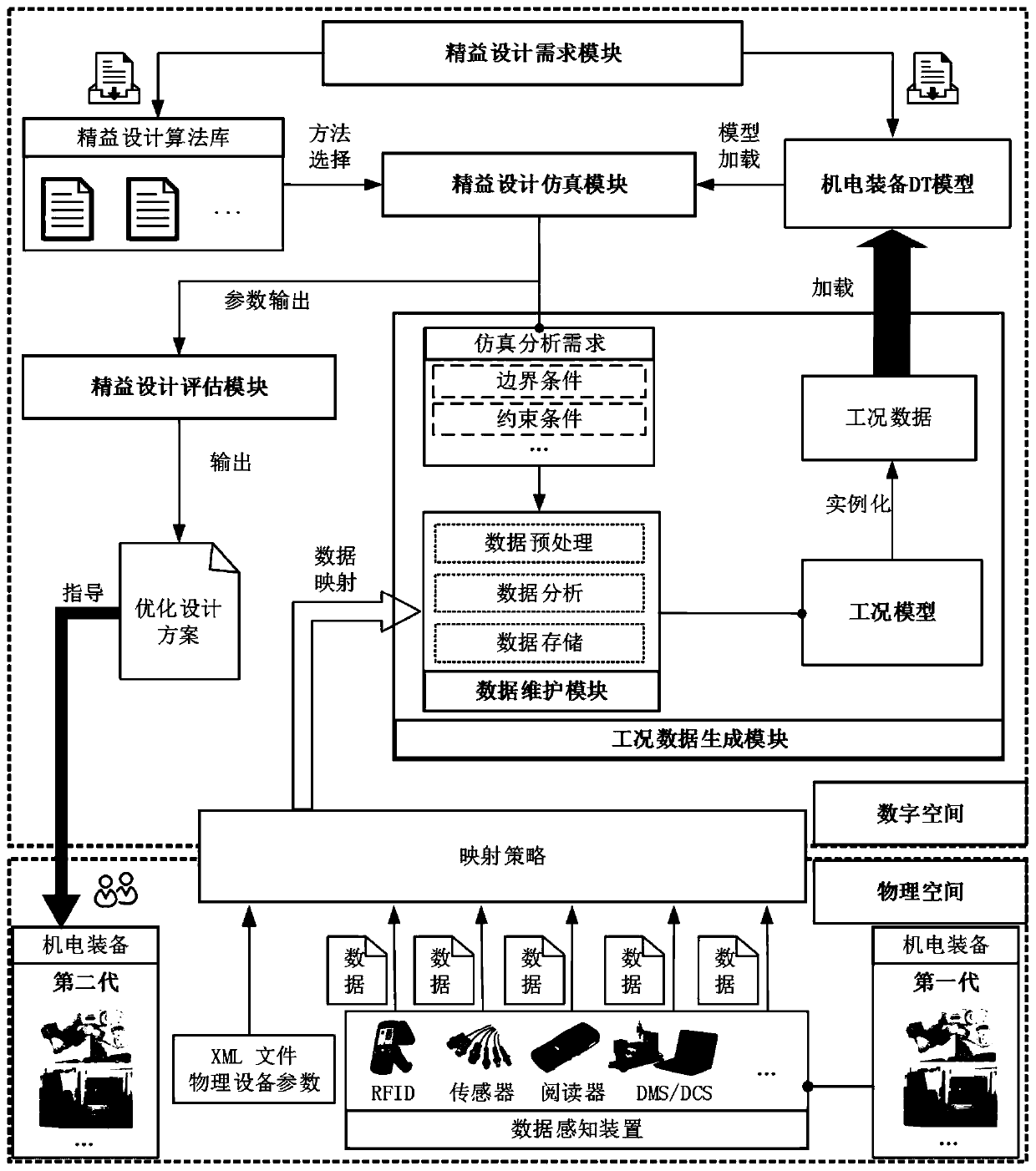

[0044] A digital twin-based lean design method for electromechanical equipment includes physical space and digital space. The physical space maps basic data to digital space through the digital twin mapping module. Such as figure 1 shown.

[0045] The physical space includes electromechanical equipment and data sensing devices.

[0046] The digital space includes a lean design requirement module, an application-oriented working condition data generation module, a lean design simulation module, and a lean design evaluation module; the lean design requirement module is used to analyze the performance indicators proposed by different equipment demanders to obtain design requirements, Provide demand guidance for the subsequent lean design simulation analysis; the data sensing device collects the basic data of electromechanical equipment and maps the basic data to the working condition data generation module through the digital twin mapping module, and the working condition data g...

Embodiment 2

[0051] A lean design method for electromechanical equipment based on digital twins, the method is as described in Example 1, the difference is that data preprocessing includes data cleaning, data integration, data transformation, and data reduction, all of which are existing conventional data processing methods. The preprocessing operation, so that the clean and tidy basic data after preprocessing is obtained. Data storage refers to storing analysis data in the distributed storage system HBase.

Embodiment 3

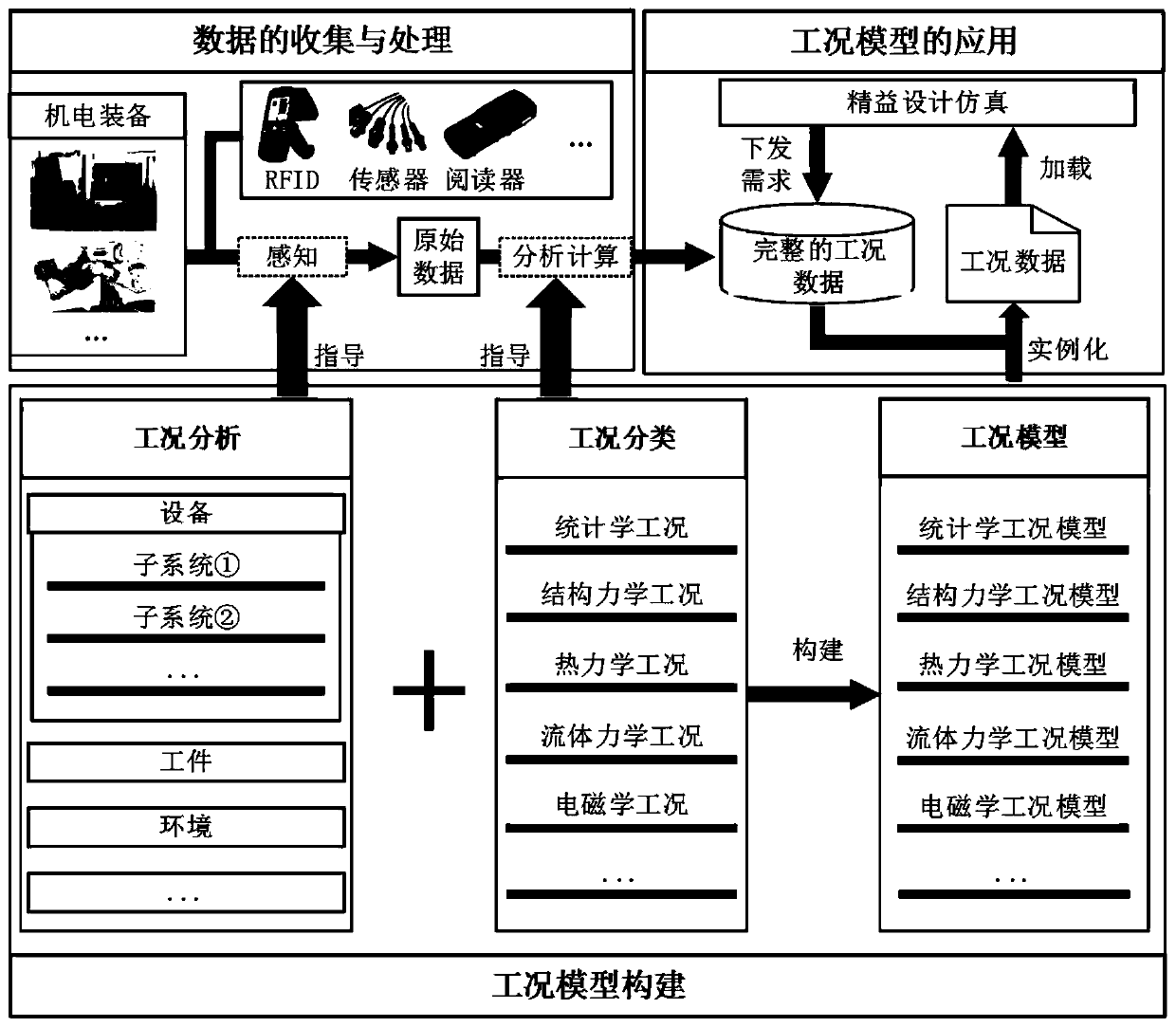

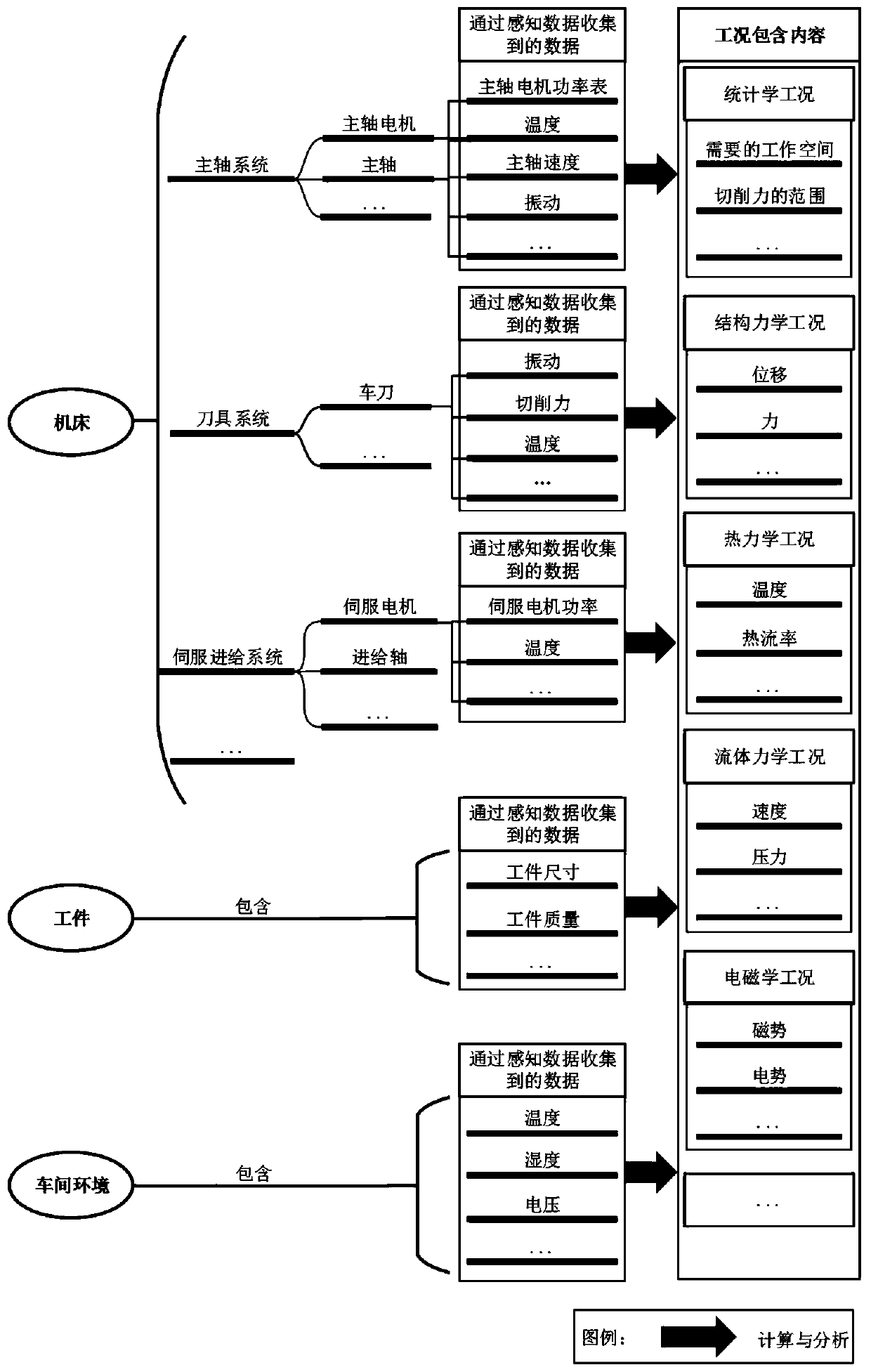

[0053] A lean design method for electromechanical equipment based on digital twins, the method is as described in Embodiment 1, the difference is that the working condition model includes statistical working conditions, model simulation-oriented structural mechanics working conditions, model-based Simulation-oriented thermodynamics cases, model-oriented hydrodynamics cases, and model-oriented electromagnetics cases. The working condition model is a complete hierarchical and clear model used to describe the working condition, which is constructed by filling in the corresponding domain knowledge of the research object. The construction and application ideas of the working condition model are as follows: figure 2 As shown, firstly, the working condition model can be divided into several elements such as equipment, workpiece and environment. Then, under the equipment working condition model, it is divided into different subsystems according to the composition or function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com