Clamping tool of thin-walled cylinder-shaped part with horn mouth and processing method

A processing method and bell mouth technology, which are applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of unguaranteed processing size and accuracy, and achieve the effects of high processing efficiency, easy processing and improved processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

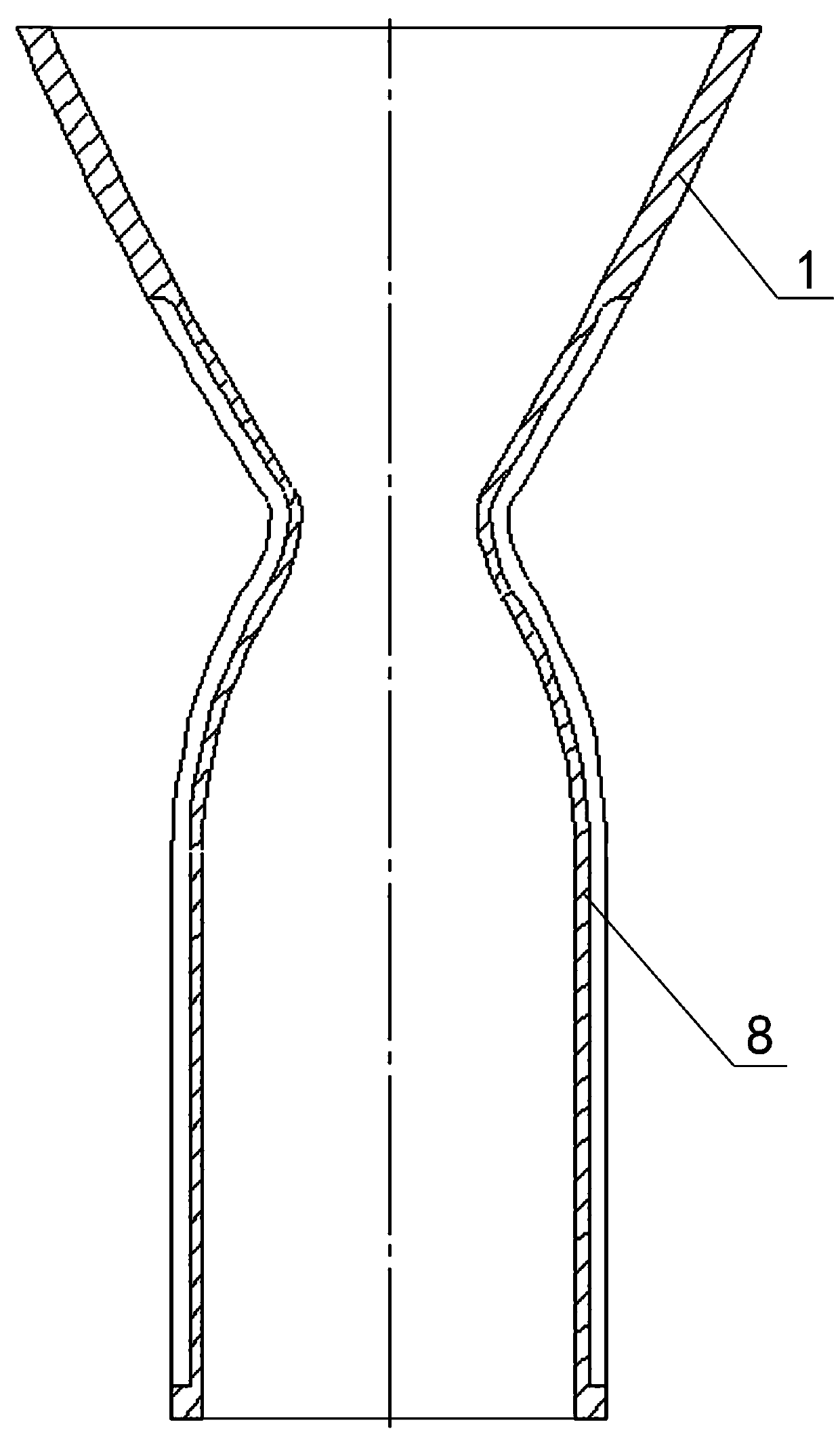

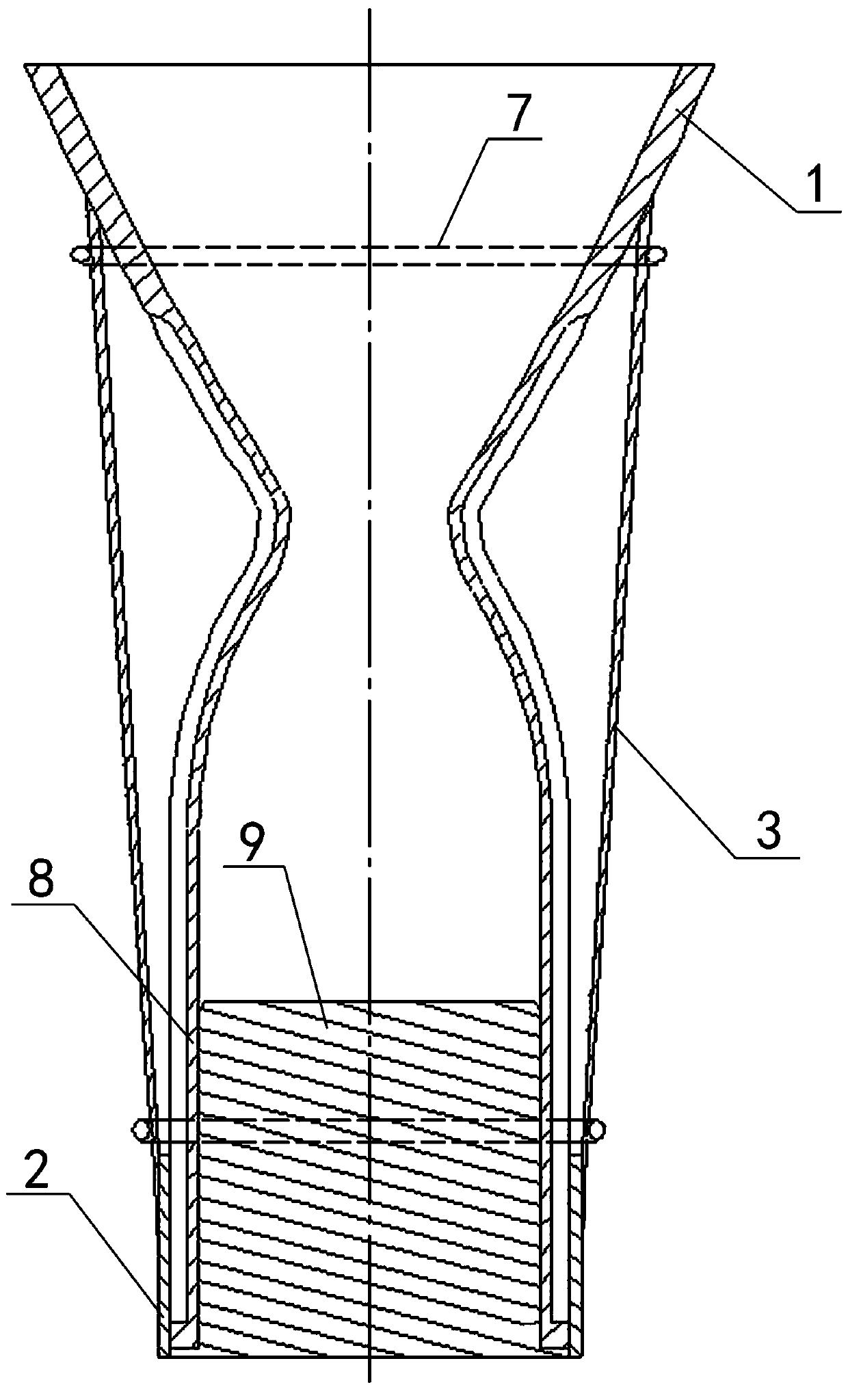

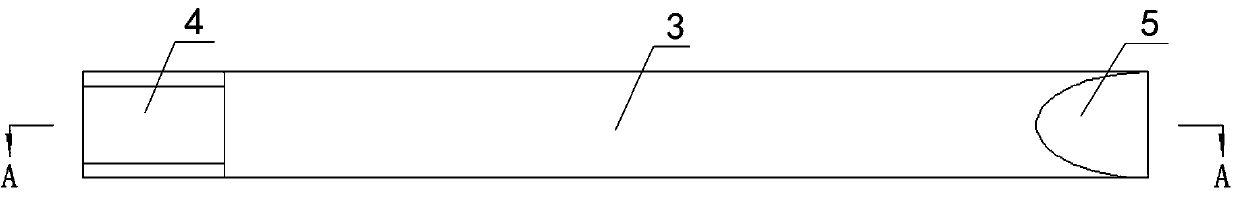

[0019] refer to Figure 1-Figure 5 , the present invention provides a clamping tool for a thin-walled cylindrical part with a bell mouth, which includes at least three supports that are uniformly distributed along the circumference of the bell mouth 1, and whose two ends are respectively abutted against the jaws 2 of the machine tool and the outer wall of the bell mouth 1 Bar 3, one end of the support bar 3 is provided with a groove 4 for accommodating the end of the jaw 2 of the machine tool, and the other end is provided with an arc-shaped recess 5 for fitting the outer wall of the bell mouth 1, and two support bars are respectively located 3 iron wires 7 at both ends for tightening all the support bars 3 , and each support bar 3 is provided with two fixing slots 6 respectively located at its two ends for embedding the iron wires 7 . When installing, first fix the cylindrical end of the part on the machine tool through the machine jaw 2, and then place all the support bars 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com