Extraction agent and method for measuring free amine content in spandex spinning stock solution

A spinning dope and extractant technology, applied in the field of spandex production process control, can solve the problems of high viscosity of spandex spinning dope, unable to meet the needs of detection, difficult to escape free amine, etc., and achieve wide applicability and good accuracy. , the extraction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

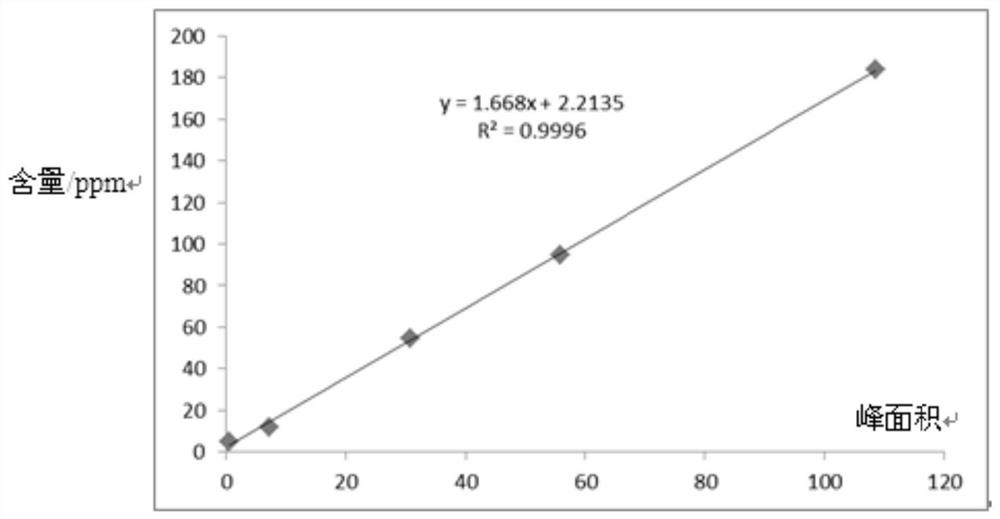

[0030] The mensuration of free amine in the spandex spinning dope produced by the continuous process of embodiment 1

[0031] This embodiment takes the spandex spinning dope produced by the continuous process of the spandex factory as an example. In the production process of the spandex spinning stock solution of this embodiment, the molar ratio (R value) of NCO to OH in the prepolymerization stage is 1.66, and the prepolymer is dissolved with solvent DMAc, and the solid content is 35wt%; in the chain extension stage, NH 2 The molar ratio (A / N) to NCO is 1.05, the amine chain extender is ethylenediamine and 1,2-propylenediamine, and the amine terminator is diethylamine.

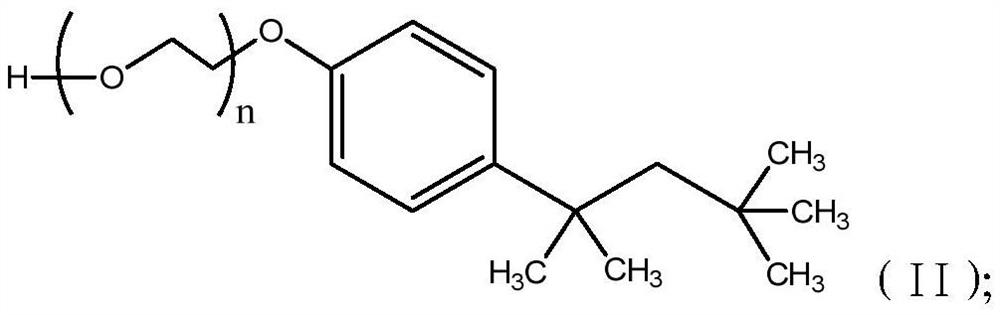

[0032] The extractant used in this example is the main reagent (purchased from TCI company, 1-propionyl-2-pyrrolidone) and auxiliary reagent (purchased from Dow Chemical, Triton x-100) composition, wherein the mass percentage of auxiliary reagents is 10%.

[0033] Take 10g (accurate to 0.1mg) of spandex ...

Embodiment 2

[0042] Example 2 Determination of free amine in spandex spinning stock solution produced by batch process

[0043] In this embodiment, the spandex spinning dope produced by the batch process in a spandex factory is taken as an example. In the production process of the spandex spinning stock solution of this embodiment, the molar ratio (R value) of NCO to OH in the prepolymerization stage is 1.80, and the prepolymer is dissolved with solvent DMAc, and the solid content is 35wt%; in the chain extension stage, NH 2 The molar ratio (A / N) to NCO is 1.05, the amine chain extender is 1,2-pentanediamine, and the amine terminator is di-n-butylamine.

[0044] The extractant used in this example is the main reagent (purchased from Huaxia Chemical Reagent Co., Ltd., 1-n-pentanoyl-2-pyrrolidone) and auxiliary reagents (purchased from Beijing Huayueyang Biology, Tritonx-114), wherein the mass percentage of auxiliary reagents is 20%.

[0045] Take 10g (accurate to 0.1mg) of spandex spin...

Embodiment 3

[0054] This embodiment takes the spandex spinning dope produced by the continuous process of the spandex factory as an example. In the production process of the spandex spinning stock solution of this embodiment, the molar ratio (R value) of NCO to OH in the prepolymerization stage is 1.70, and the prepolymer is dissolved with solvent DMAc, and the solid content is 35wt%; in the chain extension stage, NH 2 The molar ratio (A / N) to NCO is 1.03, the amine chain extender is ethylenediamine, and the amine terminator is diethylamine.

[0055] The extractant used in this example is the main reagent (TCI company, 1-acetyl-2-pyrrolidone) and auxiliary reagents (Dow Chemical, Triton x-100), wherein the mass percentage of auxiliary reagents is 20%.

[0056] Take 10g (accurate to 0.1mg) of spandex spinning stock solution in a 50mL centrifuge tube, add 30g (accurate to 0.1mg) of the above extractant, seal the centrifuge tube, and mix for 5min with a shaker; at the same time, make parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com