Preparation method of tea

A tea and fresh leaf technology, applied in the field of tea preparation, can solve the problems of lowering the quality of finished tea, dark brown product soup, and economic losses of tea processing enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

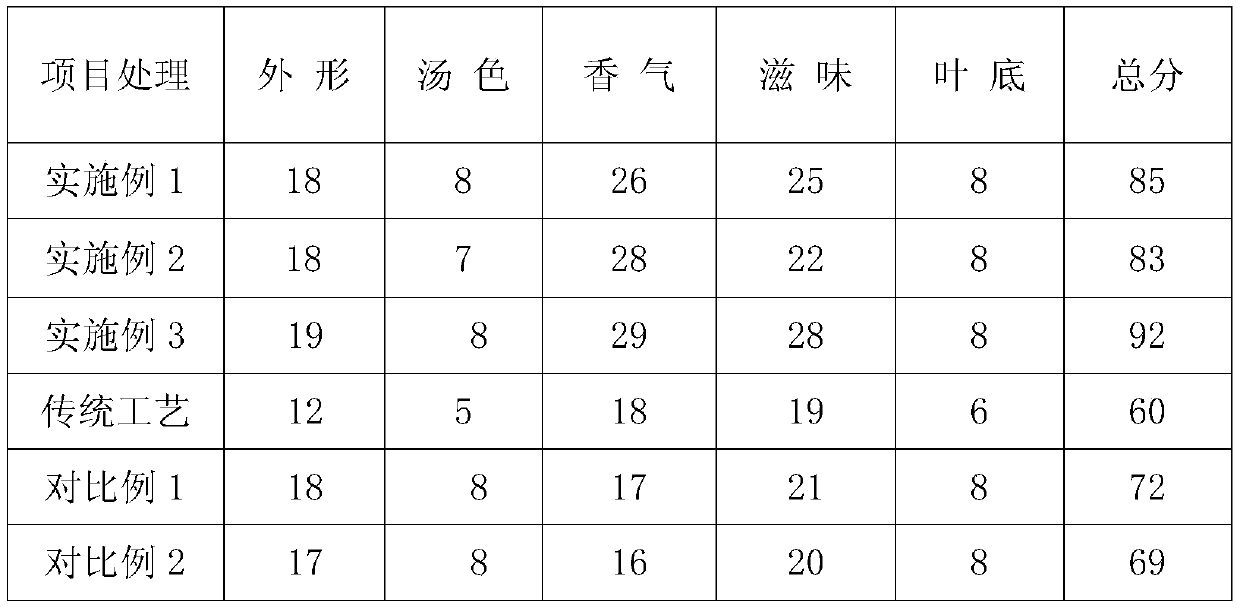

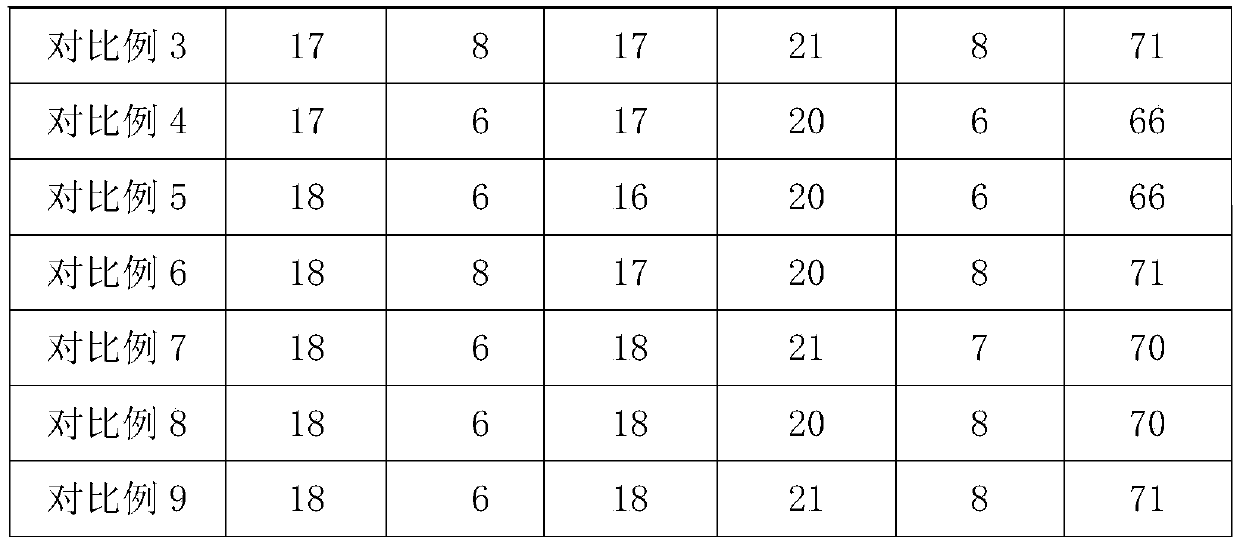

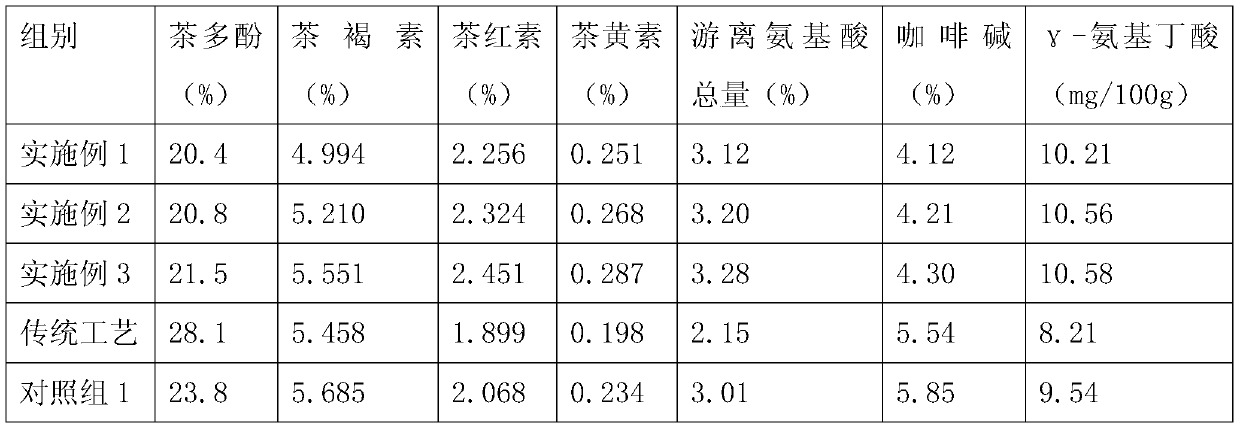

Examples

Embodiment 1

[0024] 1. Preparation of raw materials

[0025] 1. Eucommia extract is prepared by the following operations: ultrafinely pulverize the rhizome of Eucommia ulmoides, add 10-20 times the volume of Eucommia micropowder for reflux extraction for 10-15 minutes, take the filtrate, add 10-15 times the volume of water to the filter residue for extraction Reflux extraction for 10-15 minutes, take the filtrate, and combine the two filtrates.

[0026] 2. Apple extract is prepared by the following operations: take the peel of freshly picked green apples, mash them into puree, then add 8-10 times the volume of ethanol solution with a mass concentration of 80%, shake for 3-5 minutes, and then overnight Extract for 24 hours, filter to take the filtrate, recover ethanol, and steam dry to constant weight.

[0027]3. The extract of Albizia Julibrissin is prepared by the following operation: ultrafinely pulverize the dried leaves of Albizia Julibrissin, then add 10-20 times the volume of water ...

Embodiment 2

[0039] 1. Preparation of raw materials

[0040] 1. Eucommia extract is prepared by the following operations: ultrafinely pulverize the rhizome of Eucommia, add 20 times the volume of Eucommia micropowder for reflux extraction for 15 minutes, take the filtrate, add 15 times the volume of water for reflux extraction for 15 minutes, take Filtrate, the two filtrates can be combined.

[0041] 2. Apple extract is prepared by the following operation: take the peel of freshly picked green apples, mash them into a puree, then add 10 times the volume of ethanol solution with a mass concentration of 80%, shake for 5 minutes, and then extract overnight for 24 hours , take the filtrate by filtration, recover ethanol, and steam dry to constant weight.

[0042] 3. The extract of Albizia Julibrissin is prepared by the following operation: ultrafinely pulverize the dried leaves of Albizia Julibrissin, then add 20 times the volume of water of Albizia Julibrissin micropowder for reflux extracti...

Embodiment 3

[0054] 1. Preparation of raw materials

[0055] 1. Eucommia extract is prepared by the following operations: ultrafinely pulverize the rhizome of Eucommia, add 18 times the volume of Eucommia micropowder for reflux extraction for 12 minutes, take the filtrate, add 13 times the volume of water for reflux extraction for 13 minutes, take Filtrate, the two filtrates can be combined.

[0056] 2. Apple extract is prepared by the following operation: take the peel of freshly picked green apples, mash them into puree, then add 9 times the volume of ethanol solution with a mass concentration of 80%, shake for 4 minutes, and then extract overnight for 24 hours , take the filtrate by filtration, recover ethanol, and steam dry to constant weight.

[0057] 3. The extract of Albizia Julibrissin is prepared by the following operation: ultrafinely pulverize the dry leaves of Albizia Julibrissin, then add 18 times the volume of water of Albizia Julibrissin micropowder for reflux extraction fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com