Vehicle expansion tank sealing, sealing assembly, vehicle expansion tank and vehicle with expansion tank

A technology of sealing components and seals, which is applied in the field of vehicle expansion tank sealing, can solve the problems of cooling system efficiency reduction, etc., and achieve the effects of reducing expansion tank leakage and effective vehicle cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments herein will now be described more fully with reference to the accompanying drawings, in which some embodiments are shown. Like numbers refer to like elements throughout. Well-known functions or constructions are not necessarily described in detail for brevity and / or clarity.

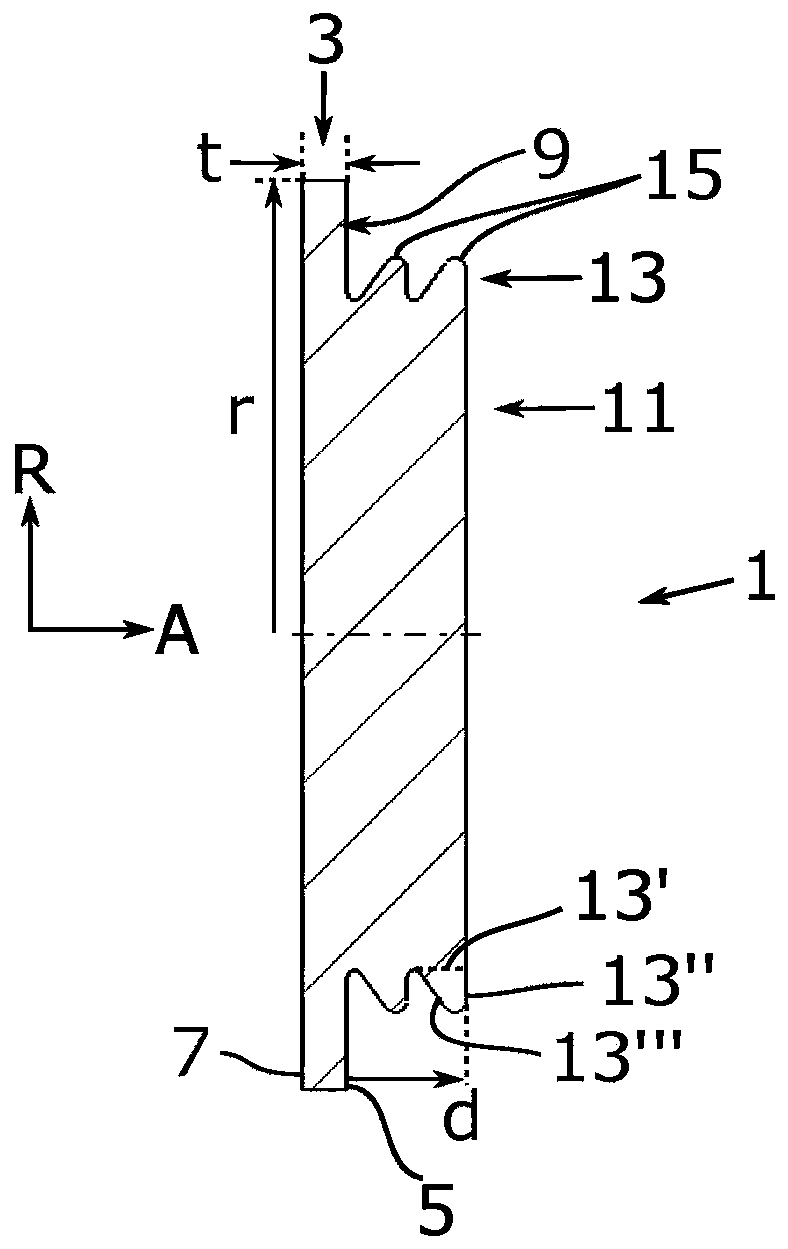

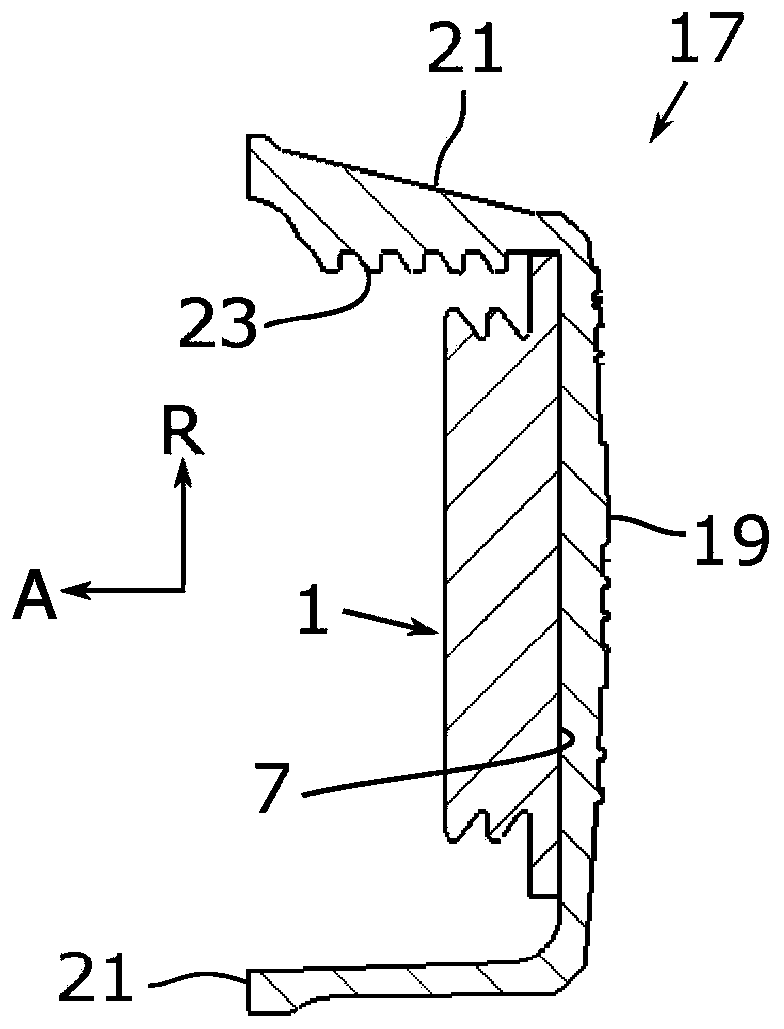

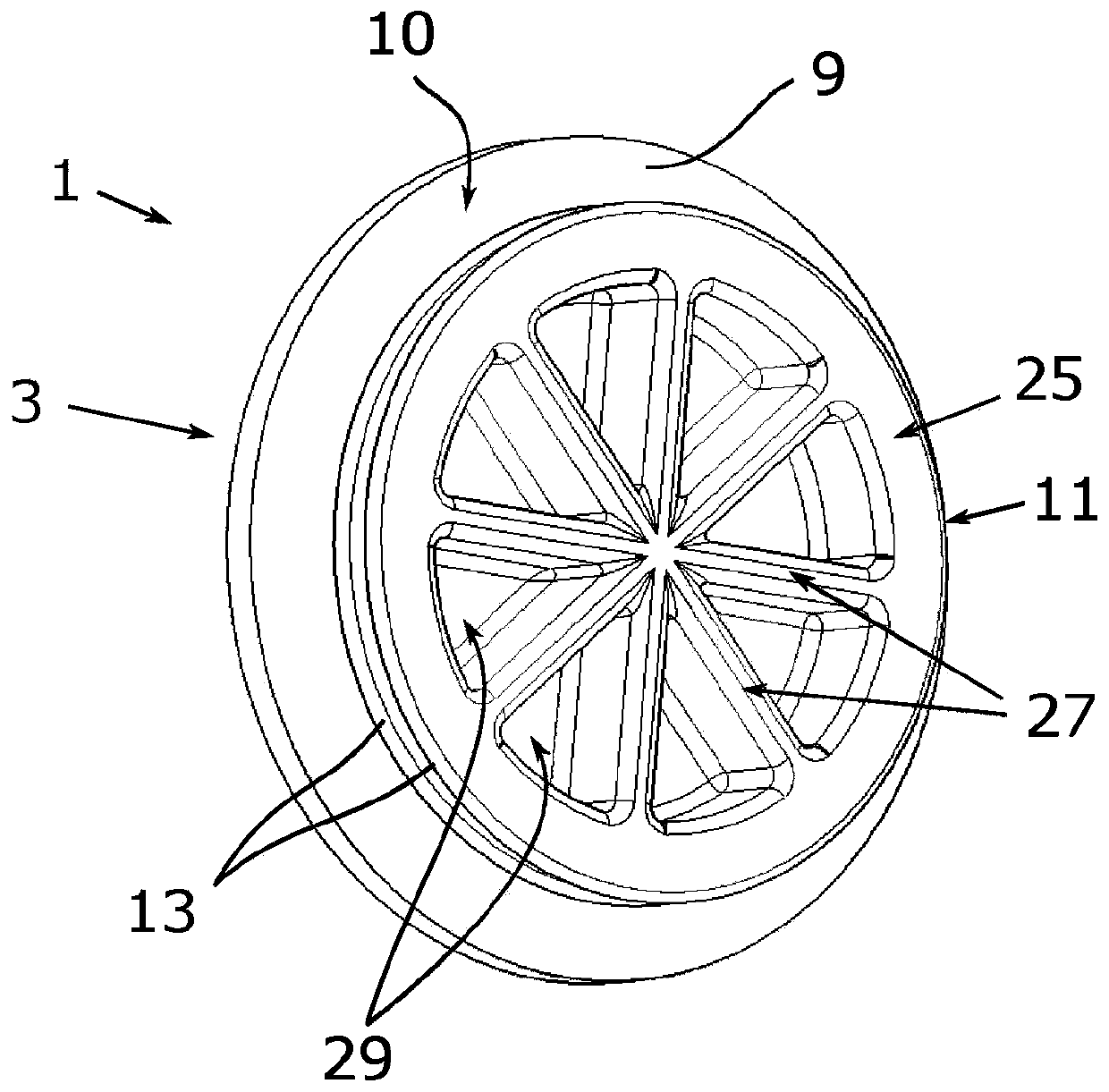

[0035] figure 1 A vehicle expansion tank seal 1 is shown. The can seal 1 comprises a generally disc-shaped portion 3 having a thickness t in the axial direction A between a first side 5 and a second side 7 . The disc-shaped portion has a radius r in the radial direction R. Directions A and R are given by figure 1 indicated by the arrow in . Select the radius r after the seal assembly / cover assembly to which the seal belongs. Such as figure 2 As shown, the radius can be selected to cover a substantial portion of the inner surface of the flat cover. In the figures herein, the disk-shaped portion is shown as being substantially circular, but it could alternatively be eg hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com