ZnO nanocluster gas-sensitive sensor taking FTO conductive glass as electrode element

A gas sensor and electrode element technology, applied in the direction of material resistance, etc., can solve the problems of poor contact between materials and electrodes, uneven coating thickness, damage to material morphology, etc., to overcome easily damaged material morphology and production costs The effect of low and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

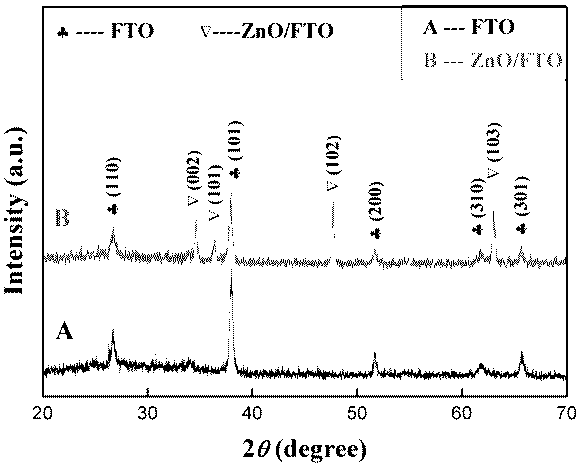

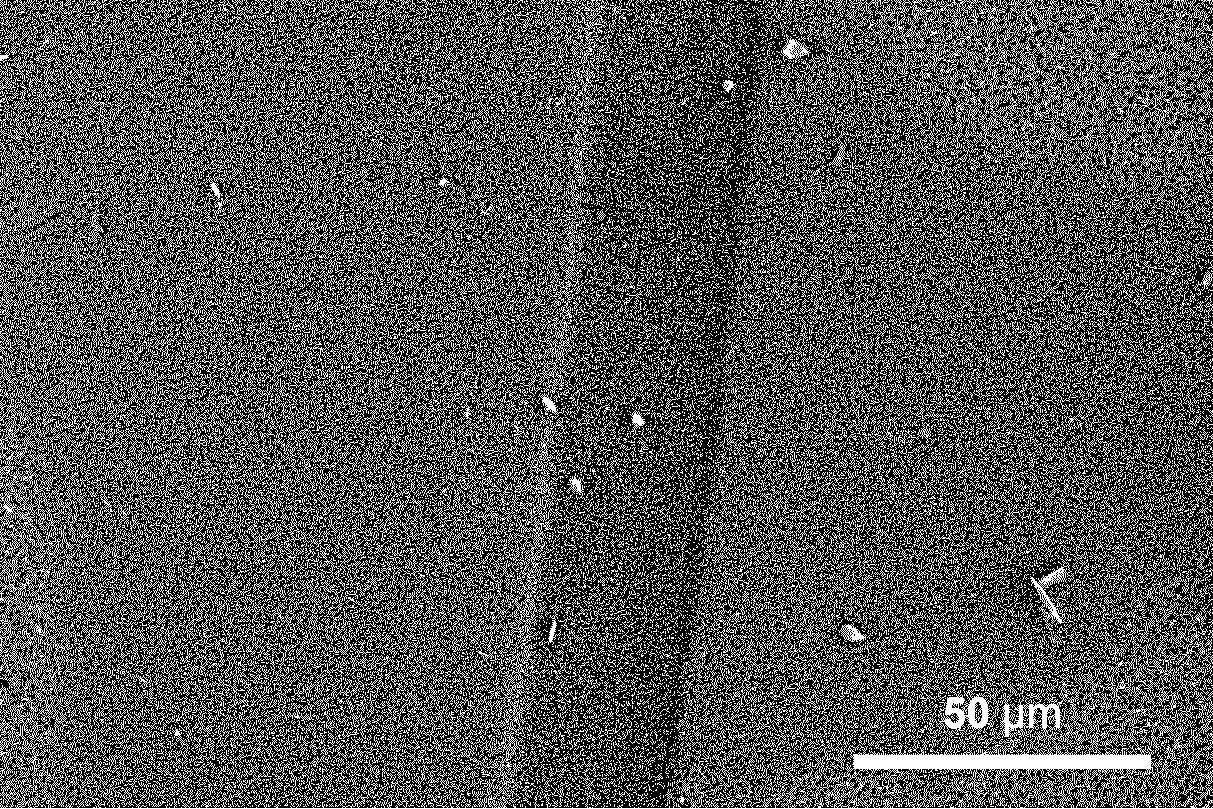

[0035] Example 1, the preparation process of in-situ growth of ZnO nano-clusters using photolithographically processed FTO conductive glass as electrode components and the test of their gas-sensing properties.

[0036] The preparation process of the gas sensor is carried out according to the following steps:

[0037] (1) Take 0.05 M zinc acetate dihydrate, 0.05 M ethylene glycol amine and appropriate amount of absolute ethanol solution to prepare the seed layer solution;

[0038] (2) Use a self-made lifting motor to move the electrode element into and out of the seed layer solution twice at a speed of 1-3 mm / s, then dry the electrode element at room temperature overnight, and then put it in a muffle furnace at 5 ℃ / The heating rate of min was annealed at 400 °C for 10 min, and the above process was repeated twice to obtain a uniform ZnO seed layer;

[0039] (3) Take 0.05 M zinc nitrate hexahydrate compound, 0.055 M hexamethylenetetramine, 0.018 M polyethyleneimine (molecular we...

Embodiment 2

[0043] Example 2, the preparation process of in-situ growth of ZnO nano-clusters using FTO conductive glass with a lithography stripe spacing of 30 μm as the electrode element and its gas-sensing performance test.

[0044] The preparation process of the gas sensor is carried out according to the following steps:

[0045] (1) Take 0.05 M zinc acetate dihydrate, 0.05 M ethylene glycol amine and appropriate amount of absolute ethanol solution to prepare the seed layer solution;

[0046] (2) Use a self-made lifting motor to move the electrode element into and out of the seed layer solution twice at a speed of 1 mm / s, then dry the electrode element overnight at room temperature, and then put it into a muffle furnace at a rate of 5 °C / min The heating rate was annealed at 400°C for 10 minutes, and the above process was repeated twice to obtain a uniform ZnO seed layer;

[0047] (3) Take 0.05 M zinc nitrate hexahydrate compound, 0.055 M hexamethylenetetramine, 0.018 M polyethyleneimi...

Embodiment 3

[0050] Example 3, using FTO conductive glass with a lithographic stripe spacing of 30 μm as the electrode element, and changing the pulling speed during the preparation of the ZnO seed layer, the preparation process of growing ZnO nanoclusters and the gas-sensing performance test.

[0051] The preparation process of the gas sensor is carried out according to the following steps:

[0052] (1) Take 0.05 M zinc acetate dihydrate, 0.05 M ethylene glycol amine and appropriate amount of absolute ethanol solution to prepare the seed layer solution;

[0053] (2) Use a self-made lifting motor to move the electrode element into and out of the seed layer solution twice at a speed of 3 mm / s, then dry the electrode element at room temperature overnight, and then put it into a muffle furnace at a speed of 5 ℃ / min The heating rate was annealed at 400 °C for 10 minutes, and the above process was repeated twice to obtain a uniform ZnO seed layer;

[0054] (3) Take 0.05 M zinc nitrate hexahydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com