PDH-demodulated polarization-maintaining grating FP cavity temperature strain simultaneous measurement device

A temperature strain and measurement device technology, applied in the field of photoelectric detection, can solve the problems that the physical environment cannot be guaranteed to be completely consistent, the offset of the grating is not the same, and the additional noise cannot be completely eliminated, so as to achieve temperature stability and anti-vibration stability The effect of good performance, reduction of extra noise, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

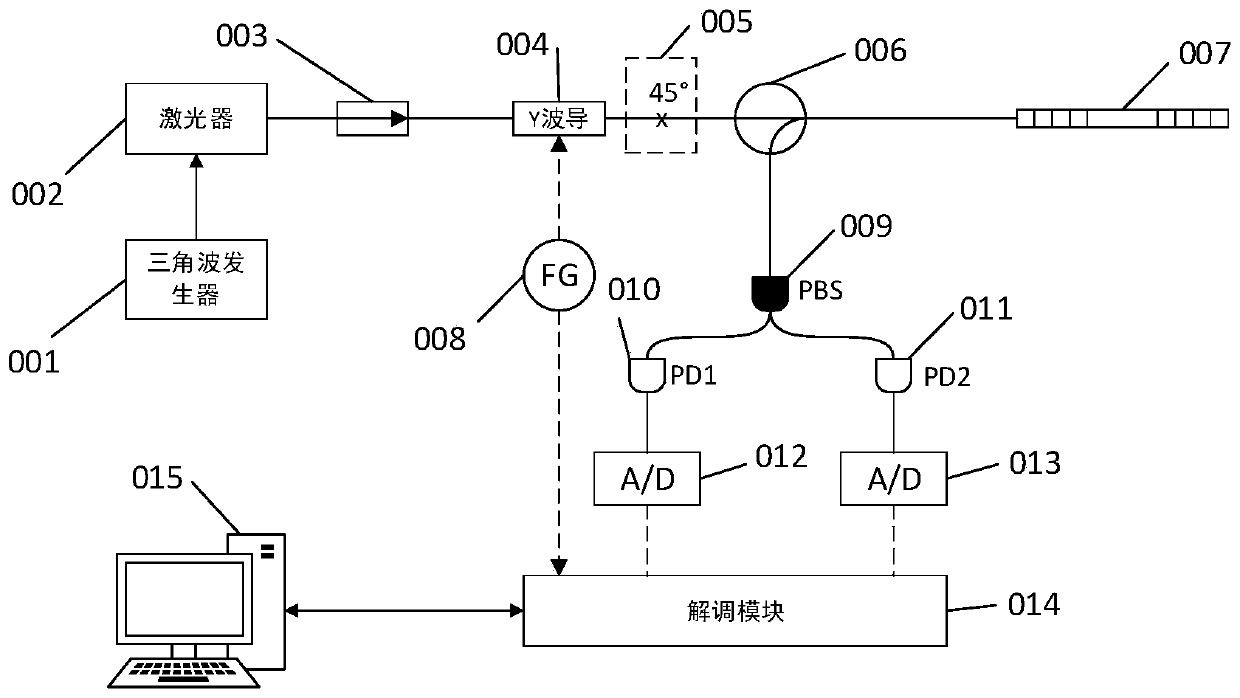

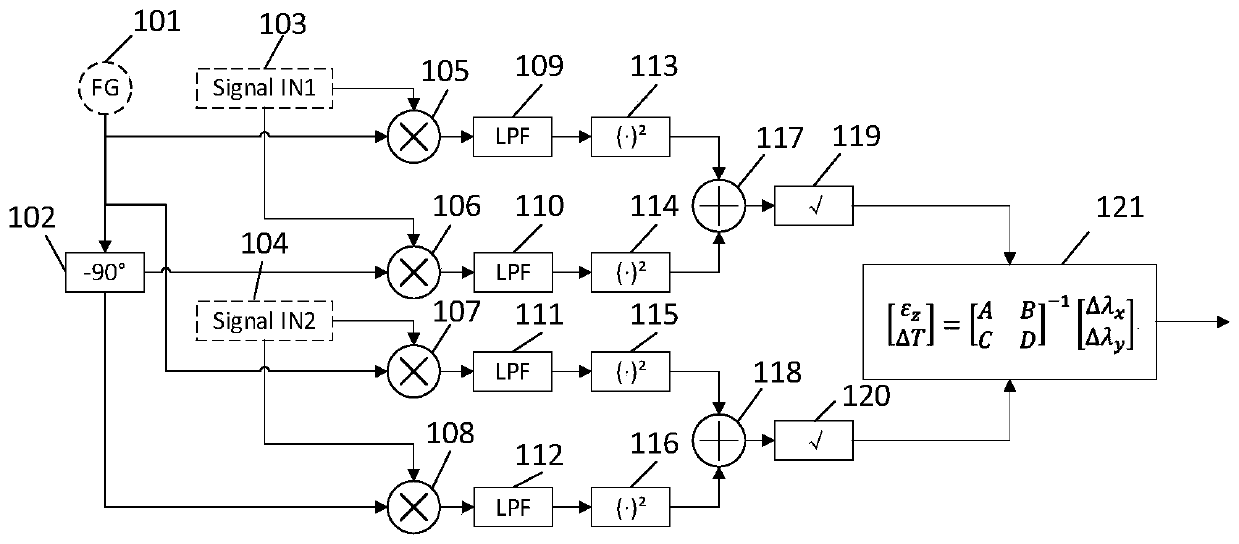

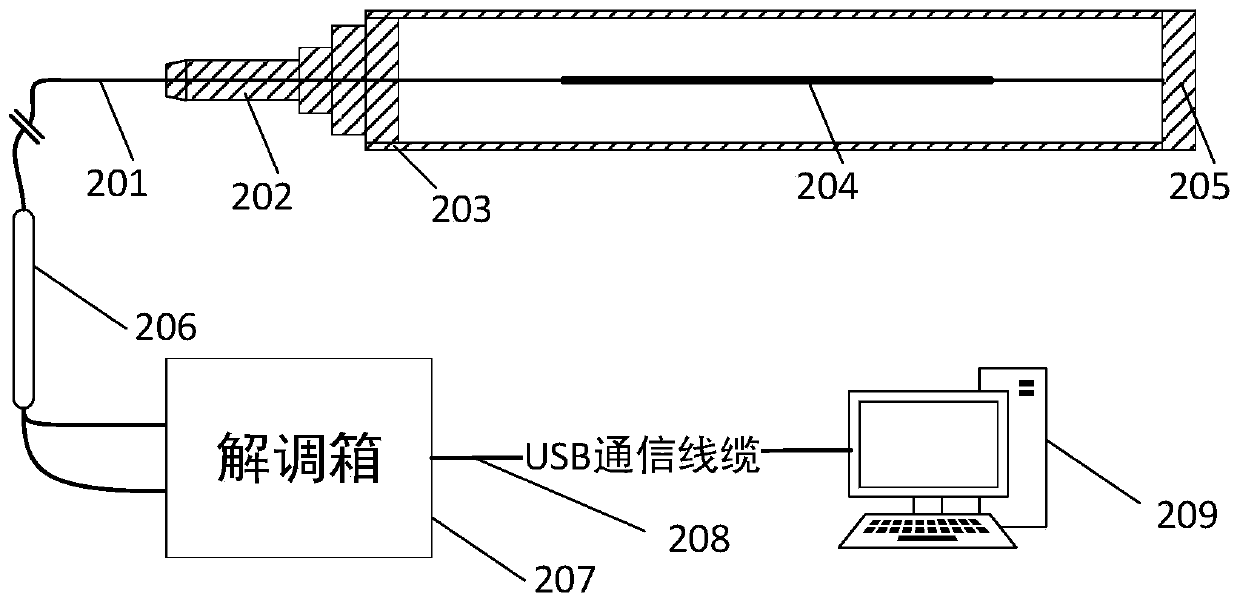

[0026] A PDH demodulated polarization maintaining grating FP cavity temperature and strain simultaneous measurement device. The narrow linewidth tunable laser is sequentially connected with the optical fiber isolator 003, the Y waveguide modulator 004, the polarization maintaining optical fiber circulator 006, and the polarization maintaining optical fiber through the polarization maintaining optical fiber. The grating FP cavity 007 is connected, and the other end of the polarization-maintaining fiber circulator 006 is connected with the polarization beam splitting module and the demodulation module 014 in turn through the polarization-maintaining fiber, and the demodulation module 014 is connected with the control terminal computer 015, and the signal generator 008 passes through The polarization-maintaining optical fiber is respectively connected with the Y-waveguide modulator 004 and the demodulation module 014, and the polarization beam splitting module is that the first out...

Embodiment 2

[0045] The present invention is based on the improvement of PDH optical fiber grating technology strain measurement method, in order to isolate the information of temperature and strain, eliminate as far as possible the problem of the environment due to temperature and strain between different optical fiber gratings, use polarization maintaining optical fiber grating to solve temperature and strain The separation problem of , which works as figure 1 shown. Frequency-sweeping laser 002 driven by triangular wave generator 001 generates frequency-sweeping laser, which is sent to Y-waveguide 004 driven by standard sine generator 008 after passing through isolator 003 for PDH signal modulation. Y-waveguide converts the two polarizations of the input laser Axis separation, and output modulated laser light on a certain polarization axis. The generated modulated laser signal is welded to the back-end polarization-maintaining fiber through 45°, so that when the transmitted light passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Attenuation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com