A method for photocatalytic oxidation of xylose using indium sulfide/nickel-iron hydrotalcite composite film

A photoelectric catalysis, hydrotalcite technology, applied in electrodes, electrolysis components, electrolysis process and other directions, can solve the problem of low reaction efficiency of photogenerated electrons and holes, and achieve the goal of promoting the separation of photogenerated electrons and holes, improving oxidation, excellent The effect of photocatalytic oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

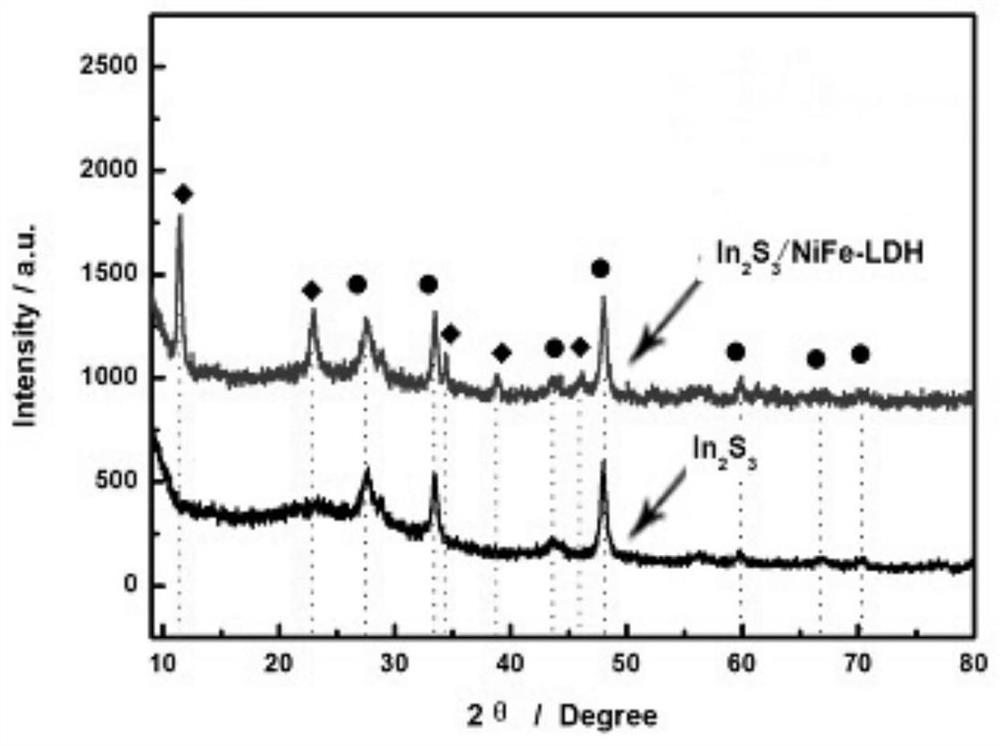

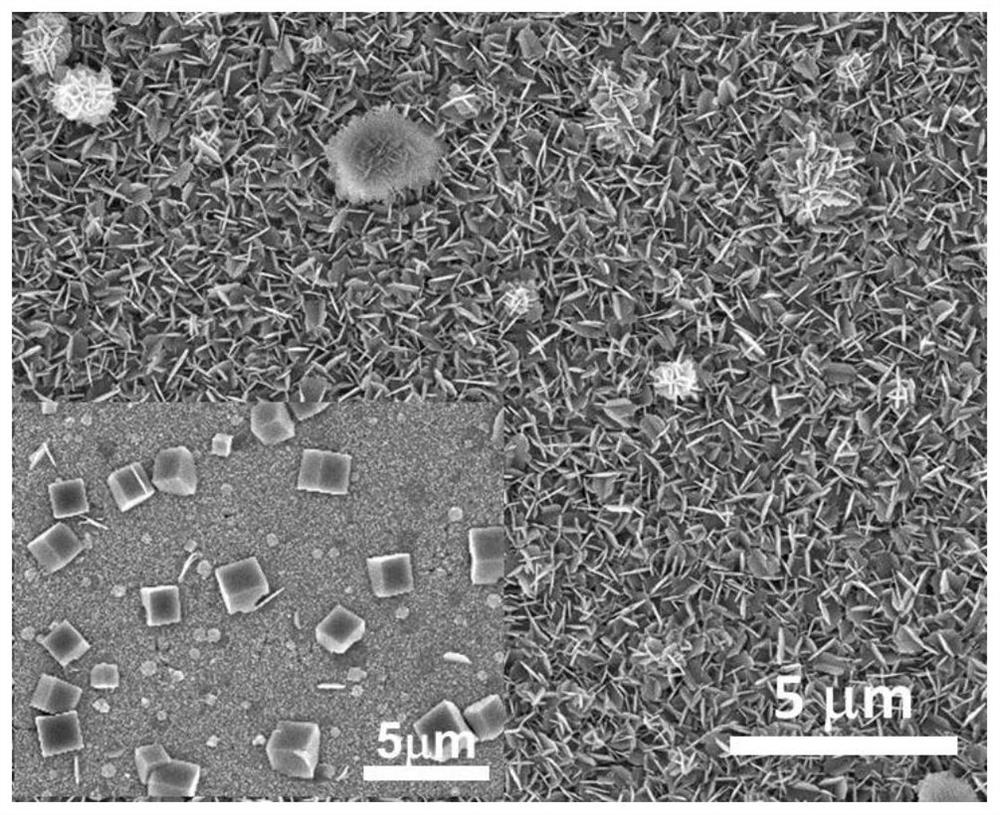

[0032] (1) Add 5.7 parts of citric acid monohydrate to 20 parts of deionized water, after fully dissolving, add 1 part of indium chloride, stir and dissolve to form an indium citrate complex solution. Dissolve 1.36 parts of thioacetamide in 20 parts of deionized water to form a thioacetamide solution. The thioacetamide solution was slowly added dropwise to the indium citrate complex solution under stirring to form a mixed solution, and transferred to the reaction kettle, and at the same time, a 10×30 mm FTO conductive glass cleaned with acetone and deionized water was placed vertically , sealed and reacted at 80° C. for 8 hours to obtain a conductive glass deposited with an indium sulfide film. The thickness of the indium sulfide film is 0.8-1 micron, and it is composed of cubic phase indium sulfide crystals with a particle size of 100-500 nm and sporadically distributed cubic phase indium sulfide crystals with a particle size of 1-2 microns;

[0033] (2) Dissolve 2.16 parts ...

Embodiment 2

[0036] (1) Add 5.7 parts of citric acid monohydrate to 20 parts of deionized water, after fully dissolving, add 1 part of indium chloride, stir and dissolve to form an indium citrate complex solution. Dissolve 1.36 parts of thioacetamide in 20 parts of deionized water to form a thioacetamide solution. The thioacetamide solution was slowly added dropwise to the indium citrate complex solution under stirring to form a mixed solution, and transferred to the reaction kettle, and at the same time, a 10×30 mm FTO conductive glass cleaned with acetone and deionized water was placed vertically , sealed and reacted at 80° C. for 8 hours to obtain a conductive glass deposited with an indium sulfide film. The thickness of the indium sulfide film is 0.8-1 micron, and it is composed of cubic phase indium sulfide crystals with a particle size of 100-500 nm and sporadically distributed cubic phase indium sulfide crystals with a particle size of 1-2 microns;

[0037] (2) Dissolve 2.16 parts ...

Embodiment 3

[0040] (1) Add 5.7 parts of citric acid monohydrate to 20 parts of deionized water, after fully dissolving, add 1 part of indium chloride, stir and dissolve to form an indium citrate complex solution. Dissolve 1.36 parts of thioacetamide in 20 parts of deionized water to form a thioacetamide solution. The thioacetamide solution was slowly added dropwise to the indium citrate complex solution under stirring to form a mixed solution, and transferred to the reaction kettle, and at the same time, a 10×30 mm FTO conductive glass cleaned with acetone and deionized water was placed vertically The sheet was sealed and reacted at 80°C for 8 hours to obtain a conductive glass deposited with an indium sulfide film. The thickness of the indium sulfide film is 0.8-1 micron, and it is composed of cubic phase indium sulfide crystals with a particle size of 100-500 nm and sporadically distributed cubic phase indium sulfide crystals with a particle size of 1-2 microns;

[0041] (2) Dissolve 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com