Preparation method of a highly conductive tensile strain responsive material

A technology of tensile strain and high conductivity, which is applied in the field of preparation of highly conductive tensile strain response materials, can solve the problems of sensitivity and stability to be further improved, and achieve good axial conductivity, good flexibility and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

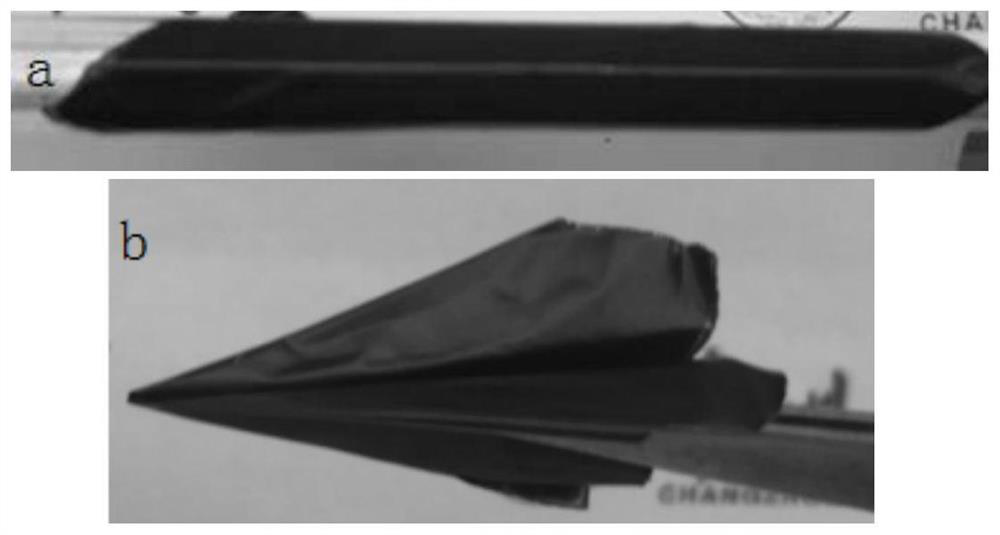

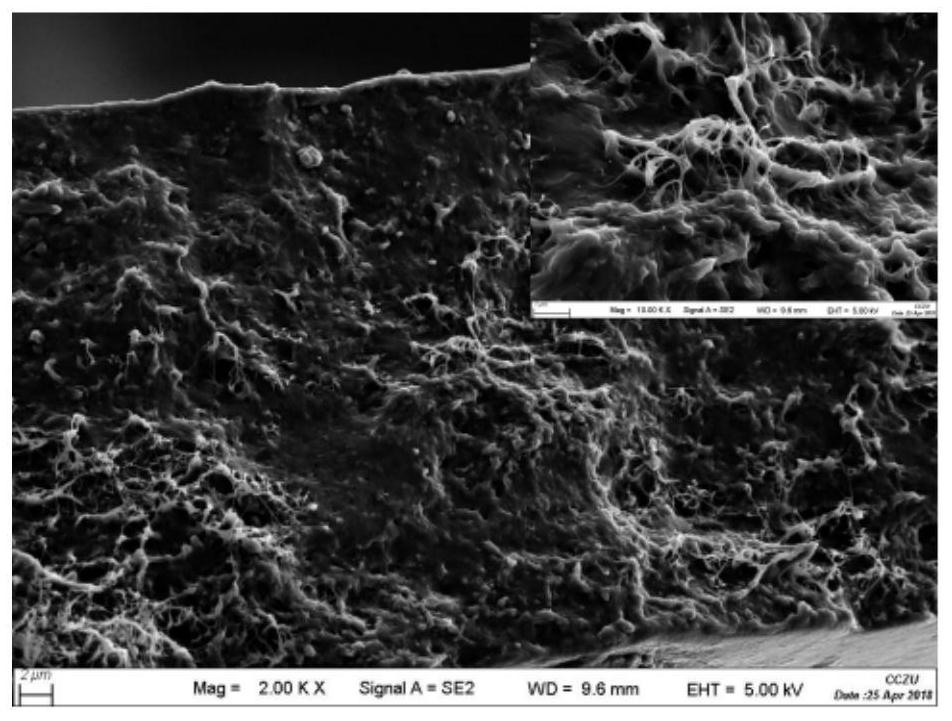

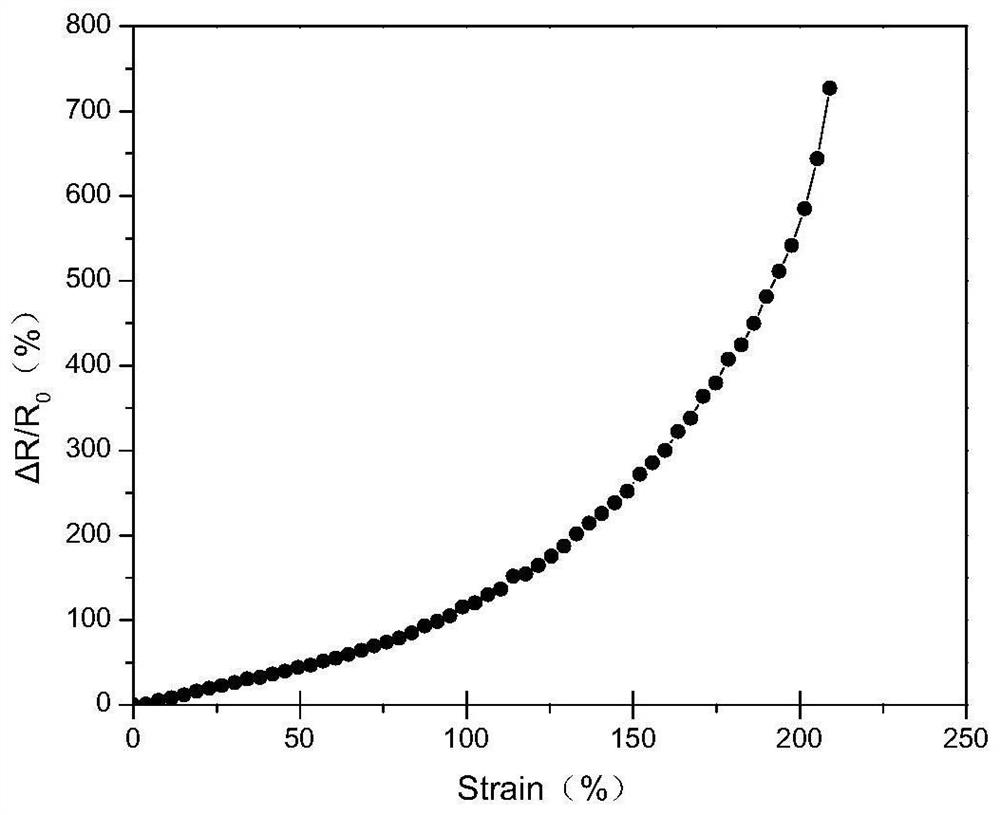

Image

Examples

Embodiment 1

[0029] (1) Preparation of reduced graphene oxide

[0030] Add the puffed expanded graphite and sodium nitrate in a mass ratio of 2:1 (1g of expanded graphite and 0.5g of sodium nitrate) into 110ml of sulfuric acid, and immediately transfer to an ice-water bath and stir for 0.5h after the addition. Then add 15g of potassium permanganate (the quality is according to (m (potassium permanganate): m (graphite) is 15:1), then add it in portions within 1h, with an interval of 3min each time, until the potassium permanganate is completely After the addition, react for 2 hours; start to heat up, and when the temperature rises to 35°C, stir for 0.5 hours, slowly drop 100ml of deionized water into the three-necked flask, and continue stirring for 0.5 hours after the addition; adjust the temperature to Stir at 98°C for 0.5h, oxidize under high temperature conditions, then add 400ml of preheated deionized water, then add 20ml of hydrogen peroxide, stir for a while, when the color gradually...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that spandex is used in step (2), and other processing means are consistent with embodiment 1. The electrical conductivity of the film material is 150 S / m, the elongation at break is 160%, and the resistance strain gage coefficient is 1.2.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is that multi-walled carbon nanotubes are used in step (2), and other processing methods are consistent with embodiment 1. The electrical conductivity of the film material is 100 S / m, the elongation at break is 130%, and the resistance strain gage coefficient is 3.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com