Fluorescent materials with aggregation-induced emission effect and circular polarization and preparation method of fluorescent materials

A technology for aggregation-induced luminescence and fluorescent materials, which is applied to the preparation of the fluorescent materials and the field of circularly polarized fluorescent materials, can solve the problems of low repetition rate and many uncontrollable factors, and achieve high solid-state luminous efficiency and remarkable aggregation-induced luminescence characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Mix 342mg (1.0mmol) 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dimethylaldehyde, 150μL (1.25mmol) 1,6-dibromohexane, 1.38g (10mmol) potassium carbonate was added to 25mL N,N-dimethylformamide, stirred and reacted at 80°C for 12 hours, the reaction solution was extracted with ethyl acetate and saturated brine, the organic phases were combined, and dry column chromatography (with The volume ratio of petroleum ether to ethyl acetate is 20:1 as the eluent) to obtain the compound of formula I.

[0059]

[0060] 2. Dissolve 52 mg (0.123 mmol) of the compound of formula I in 3 mL of ethanol, add 20 mg (0.3 mmol) of malononitrile and 50 μL of 1 mol / L sodium hydroxide in ethanol, stir and react at room temperature for 3 hours, and concentrate under reduced pressure Ethanol was removed, and column chromatography (using a mixture of petroleum ether and ethyl acetate at a volume ratio of 20:1 as the eluent) yielded the target compound with a yield of 54%.

[0061]

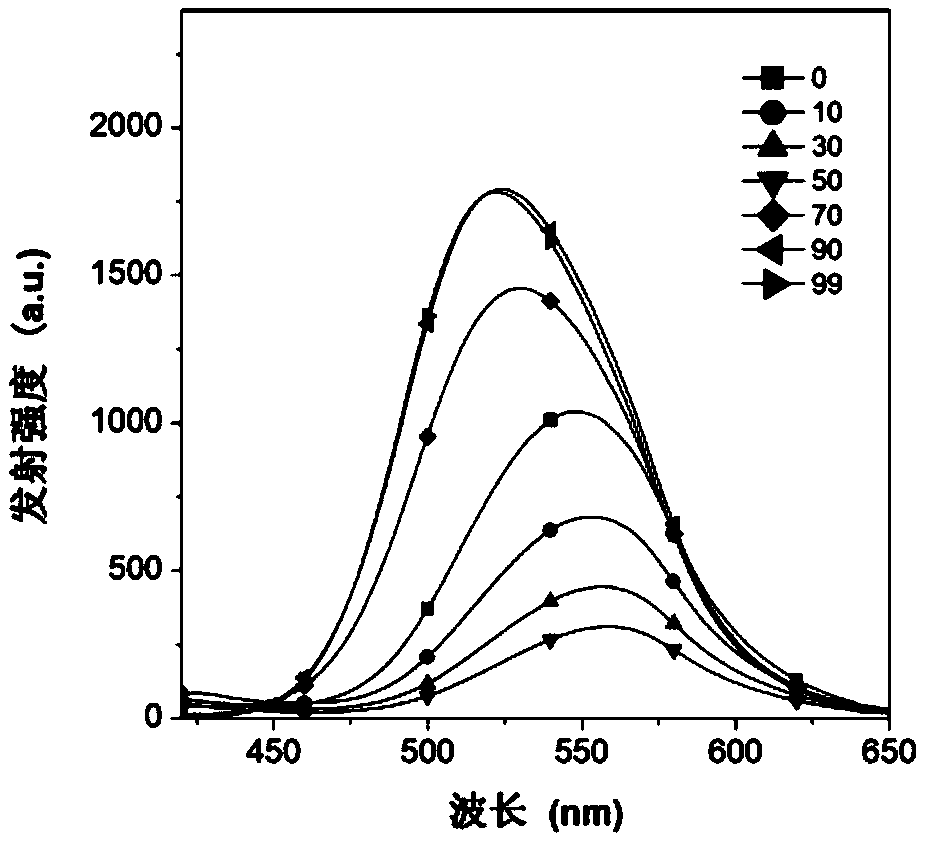

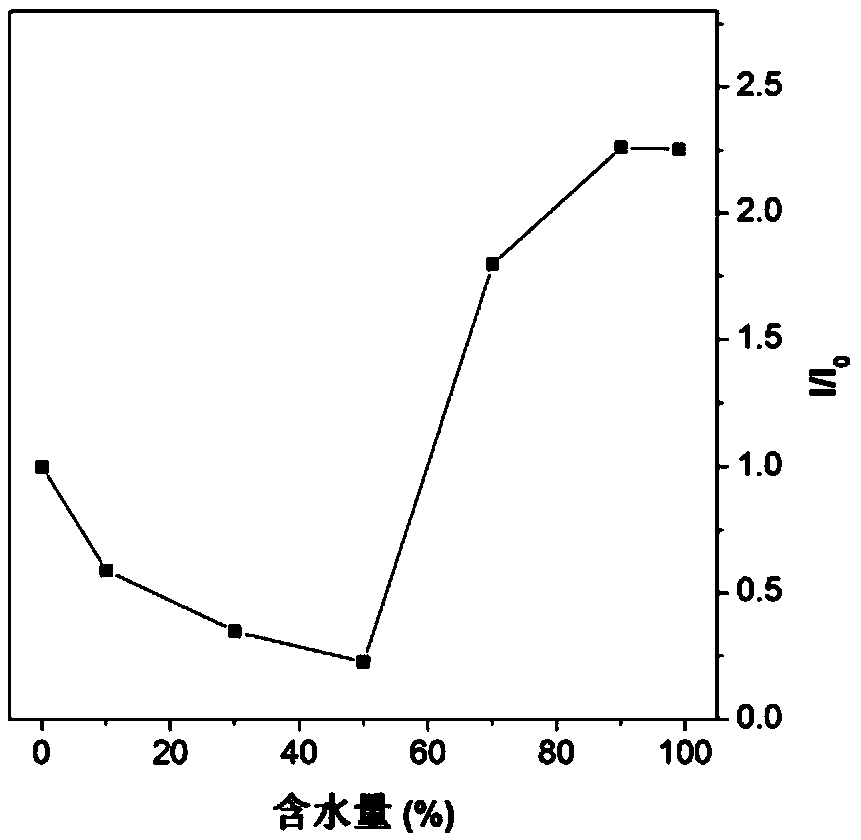

[0062] The...

Embodiment 2

[0064] 1. Add 250mg (0.5mmol) compound of formula II and 414mg (6mmol) potassium carbonate to 25mL N,N-dimethylformamide, mix well, and then use a peristaltic pump to the resulting solution at a flow rate of 0.4mL / h Add 5 mL of N,N-dimethylformamide solution containing 825 μL (0.5 mmol) of 1,6-diiodohexane, stir and react at 80°C for 12 hours, extract the reaction solution with ethyl acetate and saturated brine, and combine The organic phase was subjected to dry column chromatography (using a mixture of petroleum ether and ethyl acetate at a volume ratio of 20:1 as the eluent) to obtain the compound of formula III.

[0065]

[0066] 2. 58 mg (0.1 mmol) of the compound of formula III, 57.6 mg (0.3 mmol) of 4-trifluoromethylbenzeneboronic acid shown in formula IV-1, 5 mg (0.02 mmol) of palladium acetate, 6 mg (0.02 mmol) of triphenyl Add phosphine and 83 mg (0.6 mmol) of potassium carbonate to a mixture of 2 mL of ethylene glycol dimethyl ether and deionized water at a volume...

Embodiment 3

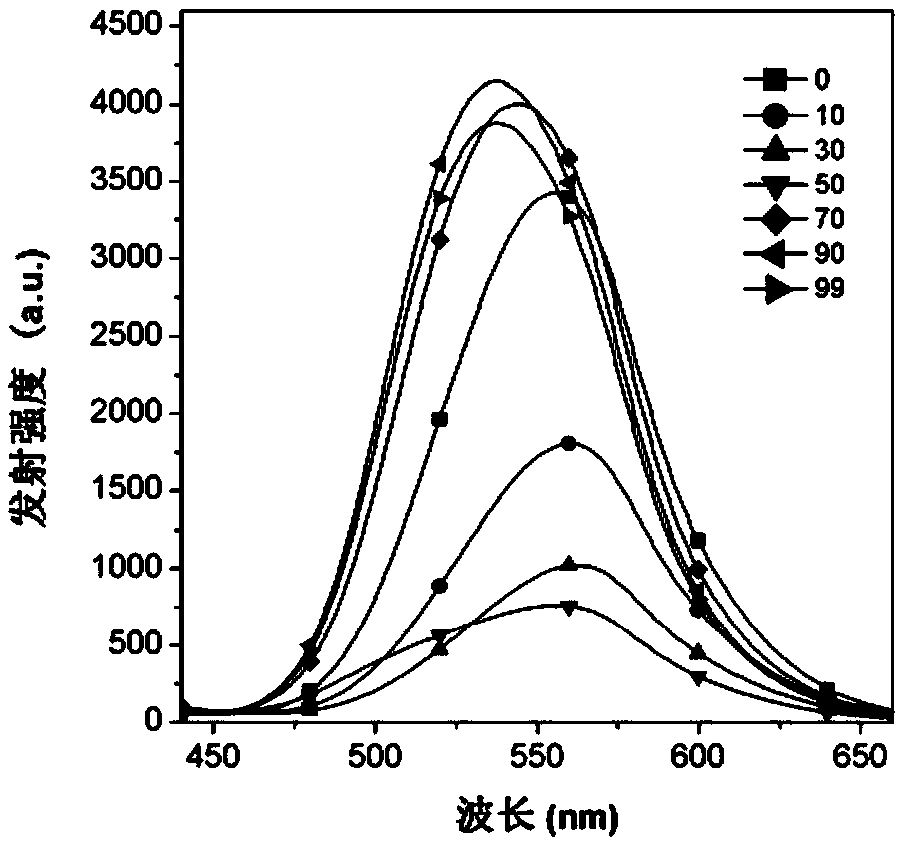

[0072] In this example, the 4-trifluoromethylphenylboronic acid in Example 2 was replaced with an equimolar amount of phenylboronic acid, and the other steps were the same as in Example 2 to obtain a fluorescent material with the following structural formula, with a yield of 70%.

[0073]

[0074] The structural characterization data of the resulting product are: 1 H-NMR (600MHz, CDCl 3 )δ (ppm): 9.00 (s, 2H), 8.54 (s, 2H, Ar H), 8.22 (s, 2H, Ar H), 7.76 (d, 2H, J=8.9Hz, Ar H), 7.69 ( d, 4H, J=7.7Hz, Ar H), 7.50(t, 4H, J=7.6Hz, Ar H), 7.43-7.38(m, 4H, Ar H), 4.06-4.01(m, 2H, CH 2 ),3.74-3.69(m,2H,CH 2 ),1.77-1.74(m,2H,CH 2 ),1.52-1.47(m,2H,CH 2 ),1.39-1.34(m,2H,CH 2 ),1.11-1.08(m,2H,CH 2 ); 13 C-NMR (151MHz, CDCl 3 )δ(ppm):156.12,151.21,139.67,139.64,134.42,132.33,130.33,130.11,129.25,128.23,127.64,127.36,126.19,125.57,122.54,113.97,112.90,84.01,70.83,28.72,22.70;HRMS( ESI-TOF)m / z:[M+Na] + C 46 h 32 N 4 o 2 Na + Theoretical value 695.2417, measured value 695....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com