Double-layer infrared film glass with anti-reflection, self-cleaning and radiation cooling functions and preparation method thereof

A radiation cooling and self-cleaning technology, which is applied in the field of energy-saving building materials, can solve the problems of increasing infrared radiation and modulating infrared absorption, and achieves the effect of simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

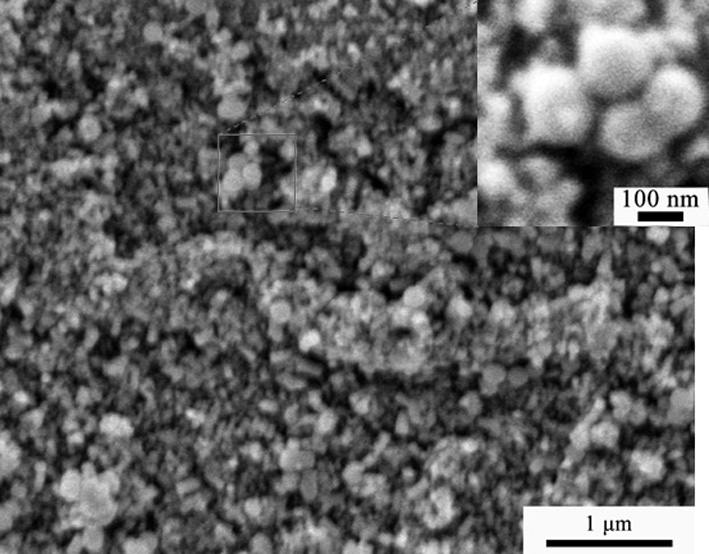

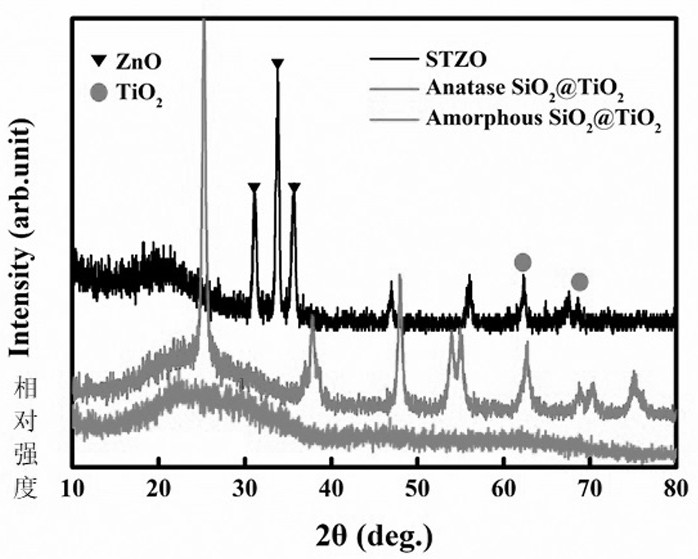

Image

Examples

Embodiment 1

[0039] A method for preparing a double-layer infrared film material with anti-reflection, self-cleaning and radiation cooling functions, comprising the following steps:

[0040] a) Preparation of silica nanospheres:

[0041] Preparation of solution A: Mix the three according to the ratio of ammonia water: ethanol: water volume ratio of 3:16:24, and prepare an 8 mol / L solution.

[0042] Preparation of solution B: prepare ethyl orthosilicate solution according to the ratio of ethyl orthosilicate:ethanol volume ratio 1:23.

[0043]Solution A was mixed with solution B and stirred at room temperature for 2 h. After the reaction was completed, it was centrifuged and washed with ethanol to finally obtain silica nanospheres with a particle size of 200 nm.

[0044] b) Preparation of titania-coated silica core-shell structure:

[0045] Preparation of solution A: According to the mass ratio of silica nanospheres and hydroxypropyl cellulose of 1:1, introduce silica nanospheres and hydr...

Embodiment 2

[0055] A method for preparing a double-layer infrared film material with anti-reflection, self-cleaning and radiation cooling functions, comprising the following steps:

[0056] a) Preparation of silica nanospheres:

[0057] Preparation of solution A: Mix the three according to the ratio of ammonia water: ethanol: water volume ratio of 3:16:24, and prepare an 8 mol / L solution.

[0058] Preparation of solution B: prepare ethyl orthosilicate solution according to the ratio of ethyl orthosilicate:ethanol volume ratio 1:31.

[0059] Solution A was mixed with solution B and stirred at room temperature for 2 h. After the reaction was completed, it was centrifuged and washed with ethanol to finally obtain silica nanospheres with a particle size of 175 nm.

[0060] b) Preparation of titania-coated silica core-shell structure:

[0061] Preparation of solution A: According to the mass ratio of silica nanospheres and hydroxypropyl cellulose of 1:1, introduce silica nanospheres and hyd...

Embodiment 3

[0069] A method for preparing a double-layer infrared film material with anti-reflection, self-cleaning and radiation cooling functions, comprising the following steps:

[0070] a) Preparation of silica nanospheres:

[0071] Preparation of solution A: Mix the three according to the ratio of ammonia water: ethanol: water volume ratio of 3:16:24, and prepare an 8 mol / L solution.

[0072] Preparation of solution B: prepare ethyl orthosilicate solution according to the ratio of ethyl orthosilicate:ethanol volume ratio 1:46.

[0073] Solution A was mixed with solution B and stirred at room temperature for 2 h. After the reaction was completed, it was centrifuged and washed with ethanol to finally obtain silica nanospheres with a particle diameter of 150 nm.

[0074] b) Preparation of titania-coated silica core-shell structure:

[0075] Preparation of solution A: According to the mass ratio of silica nanospheres and hydroxypropyl cellulose of 1:1, introduce silica nanospheres and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com