Thin-wall display card type wireless positioning terminal casing

A wireless positioning and terminal housing technology, which is applied to semiconductor devices of light-emitting elements, electrical equipment shells/cabinets/drawers, lighting devices, etc., can solve the problems of increased assembly processes, increased production costs of wireless positioning terminals, and low work efficiency. , to achieve the effect of reducing overall strength, reducing production costs and assembly costs, and reducing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

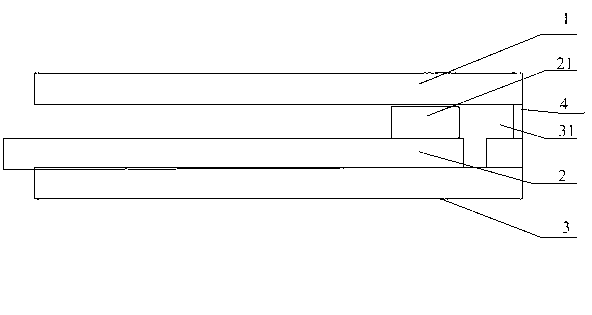

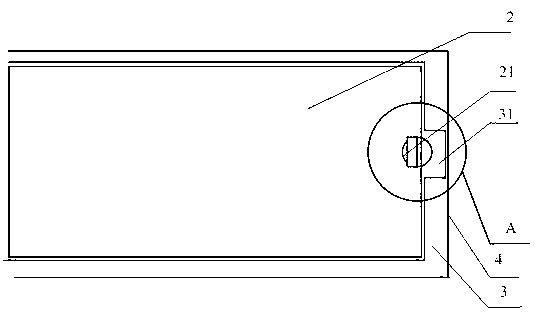

[0025] Such as figure 1 , 2 , 3 shown.

[0026] The thin-walled display card-type wireless positioning terminal housing is mainly composed of an upper cover plate 1, a lower cover plate 3, and a circuit board 2 arranged between the upper cover plate 1 and the lower cover plate 3, and the circuit board 2 is provided with There is an LED lamp 21 , and the upper cover 1 is fastened and connected with the lower cover 3 through the shell wall 4 connected on the plane of the lower cover 3 .

[0027] The LED lamp 21 is arranged near the housing wall 4 .

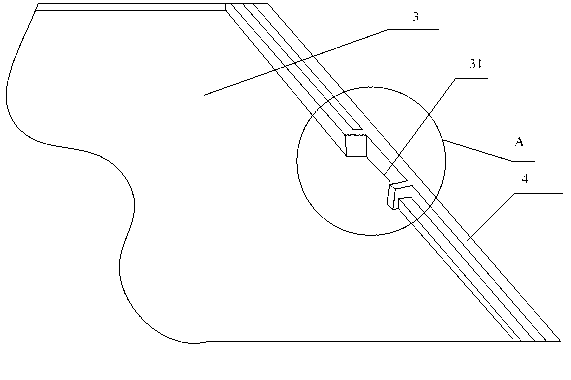

[0028] The lower cover 3 is provided with a thin-walled groove 31 close to the shell wall 4 of the LED lamp 21 , and the lamp cap of the LED lamp 21 is disposed inside the thin-walled groove 31 .

[0029] 4. The thin-wall display card type wireless positioning terminal housing according to claim 3, wherein the groove depth of the thin-wall groove 31 is 10mm.

[0030] The wall thickness of the housing wall 4 of the lower cover pl...

Embodiment 2

[0033] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that a convex lens 5 is embedded inside the thin-walled groove 31 , and the convex lens 5 is arranged between the housing wall 4 and the lamp cap of the LED lamp 21 .

[0034] Due to the influence of the light transmission effect of the housing wall 4 , in view of this technical problem, the present invention also inlays a convex lens 5 inside the thin-walled groove 31 , and the convex lens 5 is arranged between the housing wall 4 and the lamp cap of the LED lamp 21 . In this way, the light emitted by the lamp head of the LED lamp 21 gathers the light at one point through the function of the convex lens 5, and the focal point of the convex lens 5 just hits the housing wall 4, so that the source light brightness of the housing wall 4 increases. And solve the problem of poor light transmission effect of the housing wall 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com