Hybrid vehicle energy recovery system and recovery method

A hybrid vehicle and hybrid system technology, applied in electric vehicles, braking safety systems, electric braking systems, etc., can solve problems affecting the user's driving experience, torque fluctuations, etc., to increase energy recovery power, reduce Battery temperature rise rate, the effect of reducing battery temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

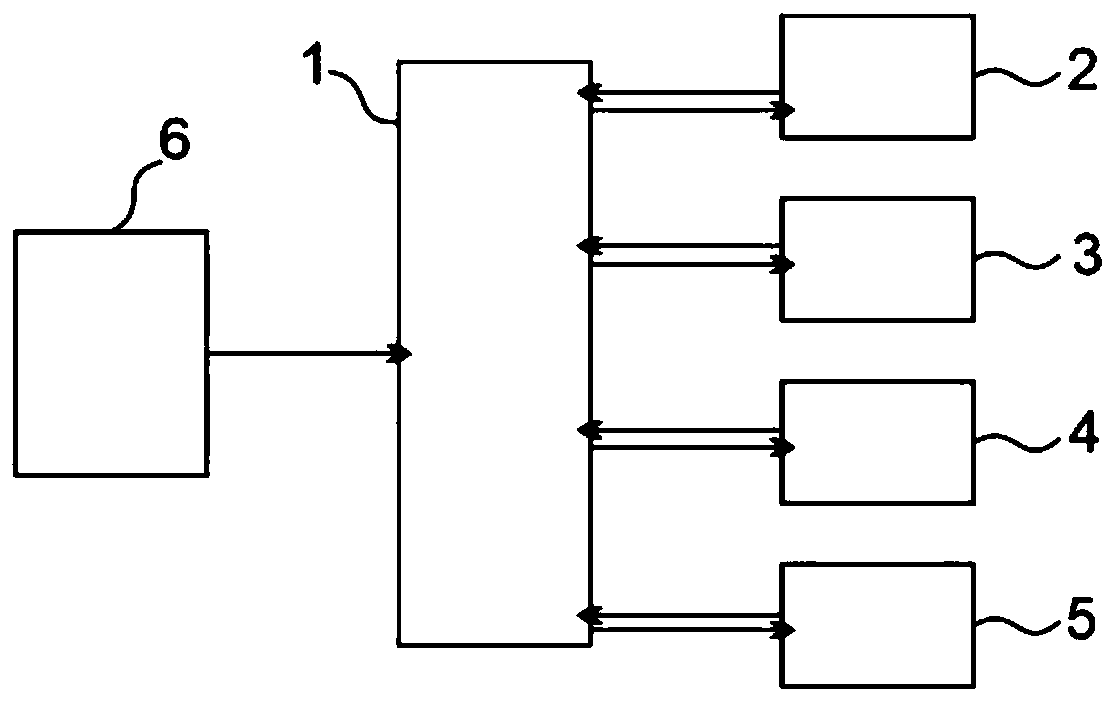

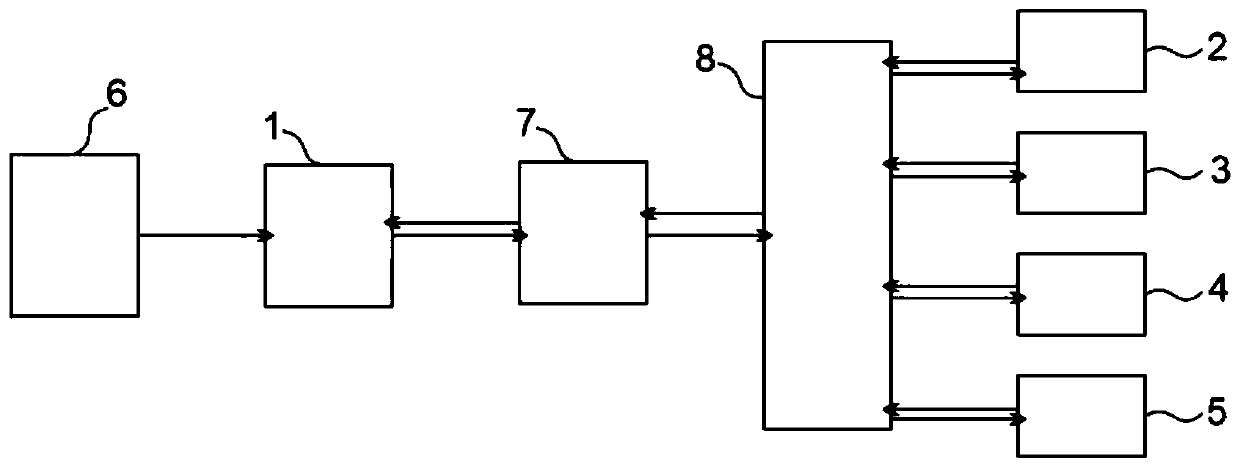

[0053] Such as Figure 1 to Figure 4 Shown: a hybrid electric vehicle energy recovery system, including a main control module 1, a motor control module 2, a battery management system 3, a braking module 4, an information receiving module 8 and a brake pedal travel sensor 6;

[0054] The main control module 1 is used to collect the detection data of the brake pedal stroke sensor 6, and send the information to the motor control module 2 according to the current state information of the motor received by the information receiving module 8 and the internal information of the battery pack. Whether to carry out energy recovery and recovery power demand information instructions, send information instructions to the battery management system 3 whether the main relay of the battery pack is allowed to be opened or closed; Dynamic ability;

[0055] The motor control module 2 diagnoses the current state of the motor in real time, and performs energy recovery or maintains the original sta...

Embodiment 2

[0077] Such as Figure 1 to Figure 4 Shown: a hybrid electric vehicle energy recovery system, including a main control module 1, a motor control module 2, a battery management system 3, a braking module 4, an information receiving module 8 and a brake pedal travel sensor 6;

[0078] The main control module 1 is used to collect the detection data of the brake pedal stroke sensor 6, and send the information to the motor control module 2 according to the current state information of the motor received by the information receiving module 8 and the internal information of the battery pack. Whether to carry out energy recovery and recovery power demand information instructions, send information instructions to the battery management system 3 whether the main relay of the battery pack is allowed to be opened or closed; Dynamic ability;

[0079] The motor control module 2 diagnoses the current state of the motor in real time, and performs energy recovery or maintains the original sta...

Embodiment 3

[0102] Embodiment 3: the difference with embodiment 1 or embodiment 2 is:

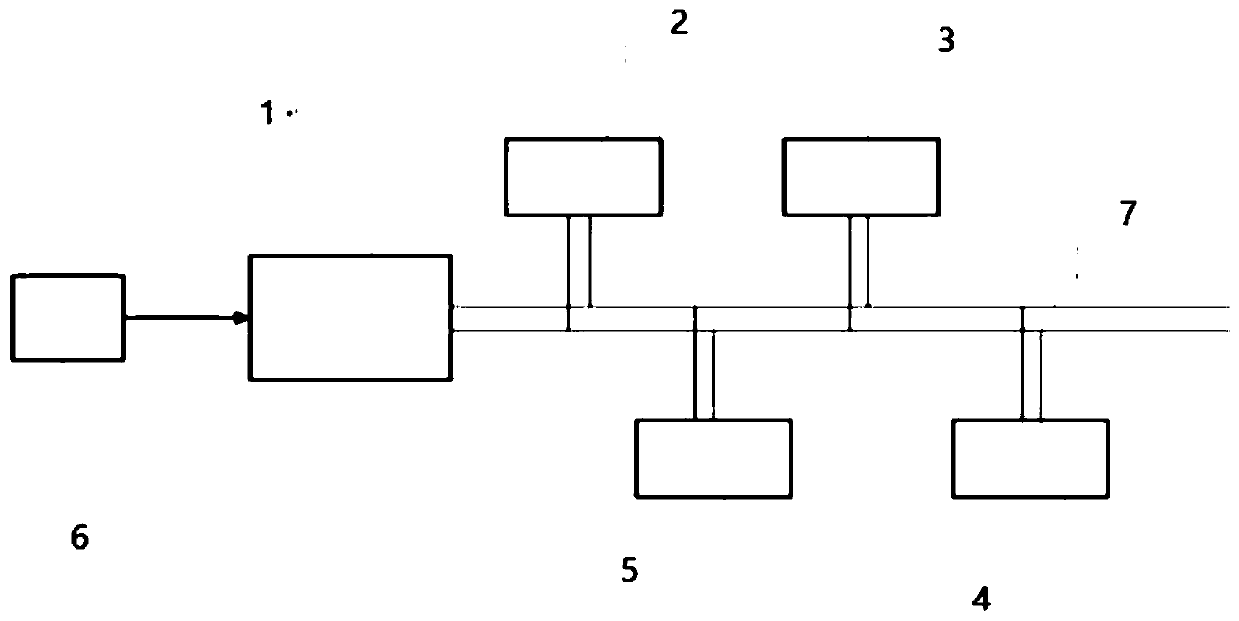

[0103] Specifically, other control modules 5 can be any control module in the above-mentioned technical solutions that can realize the functions in the book, or a third-party control module (such as instrument, multimedia, etc.) Send it to the main control module through the communication module 7.

[0104] Preferably, the communication module 7 is a CAN bus, and the brake pedal stroke sensor 6 is connected to the main control module 1 or other control modules 5 through hard wires.

[0105] In addition, the main control module 1 can also control and jump over other functions in the hybrid system according to driving demands.

[0106] The above-mentioned embodiment 1-embodiment 3 can all be used to monitor the working conditions of sudden braking, and the energy recovery can keep the braking torque corresponding to the current recovered power unchanged, minimizing the impact on the braking process; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com