Electric steaming pot

An electric steamer and steam technology, which is applied to steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of slow steam speed, low outlet steam temperature, and long heating time, and achieve short pipeline loops and high steam volume. Big, fast steam effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

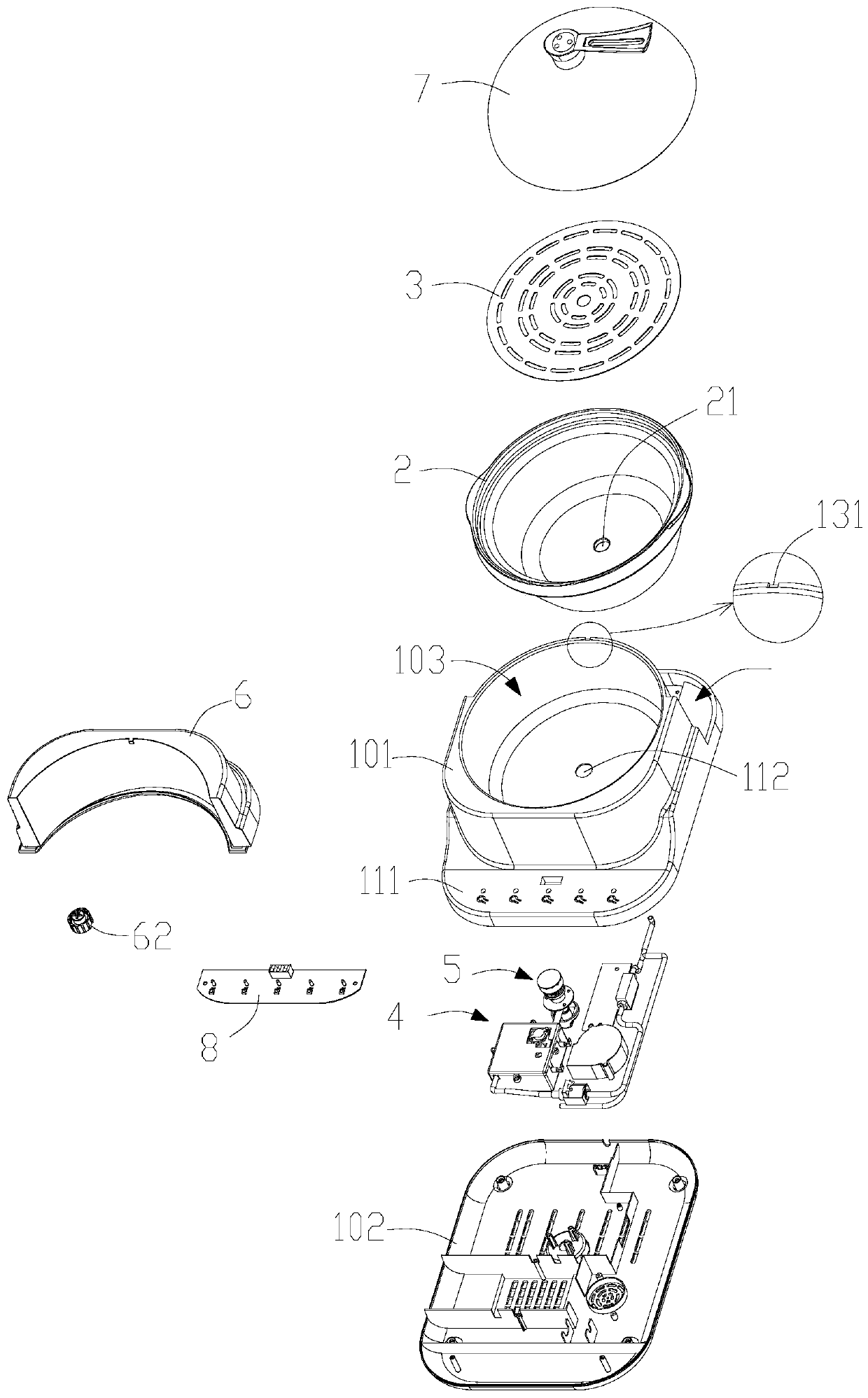

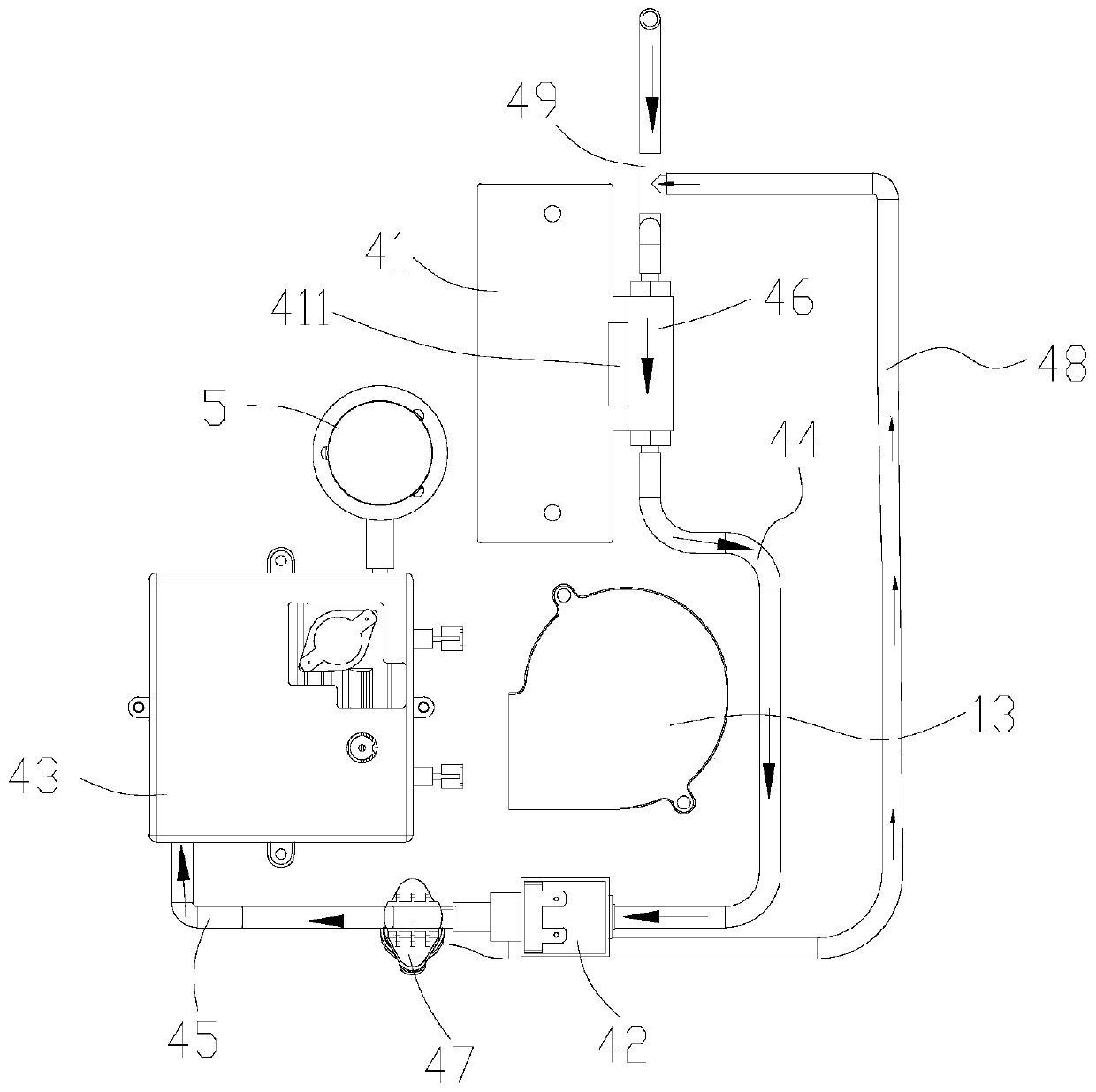

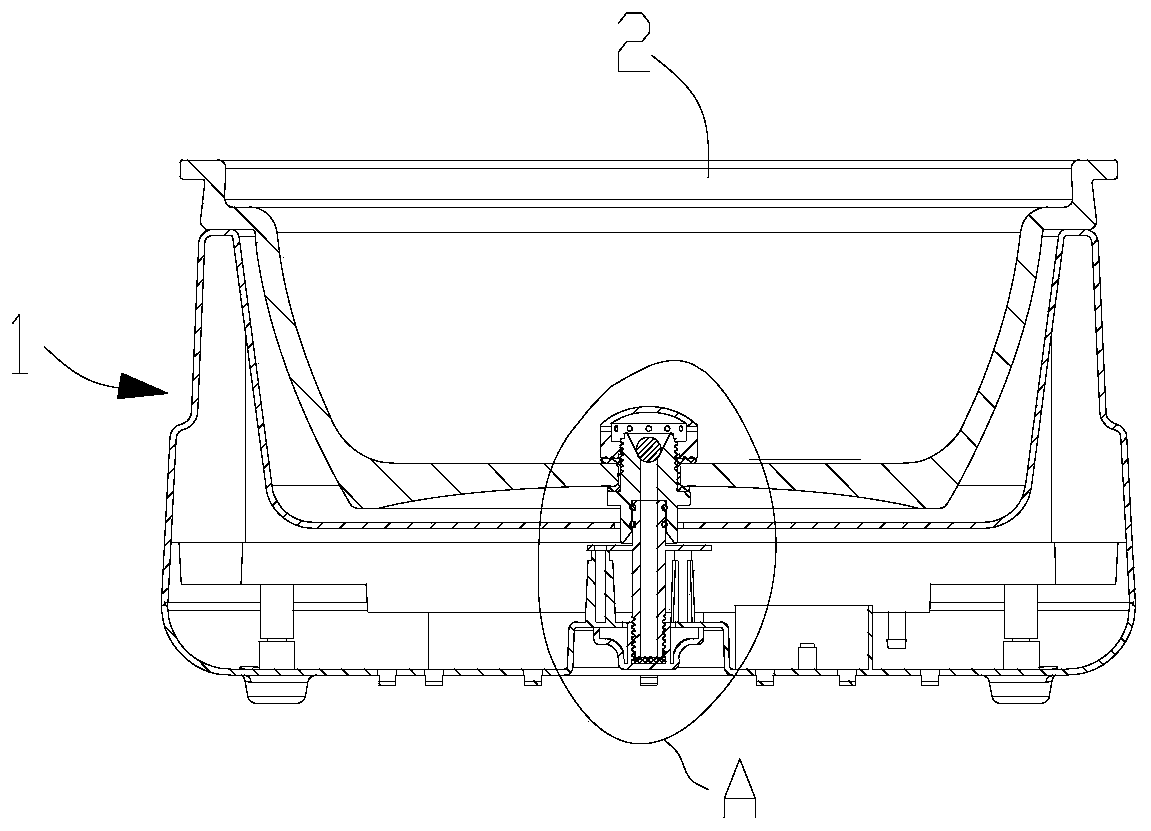

[0041] see Figure 1 to Figure 23 , an electric steamer, which includes a housing 1, a pot body 2, a steaming plate 3, a steam assembly 4, a nozzle assembly 5 and a water tank 6, the housing 1 is provided with a pot groove 103 with an upper side opening, and the pot body 2 Installed in the pot tank 103, the steam plate 3 is set in the pot body 2, the steam assembly 4 and the spray head assembly 5 are set inside the casing 1, and the water tank 6 is set in the casing 1; the steam assembly 4 includes a power board 41, a water pump 42 and a steam generator 43, the water pump 42 and the steam generator 43 are electrically connected to the power board 41, and the water inlet of the water pump 42 is connected to the The water tank 6 is connected through the first pipe body 44, the water outlet of the water pump 42 is connected with the water inlet of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com