Ready-to-eat rice soak solution and high-quality ready-to-eat soft rice preparation method

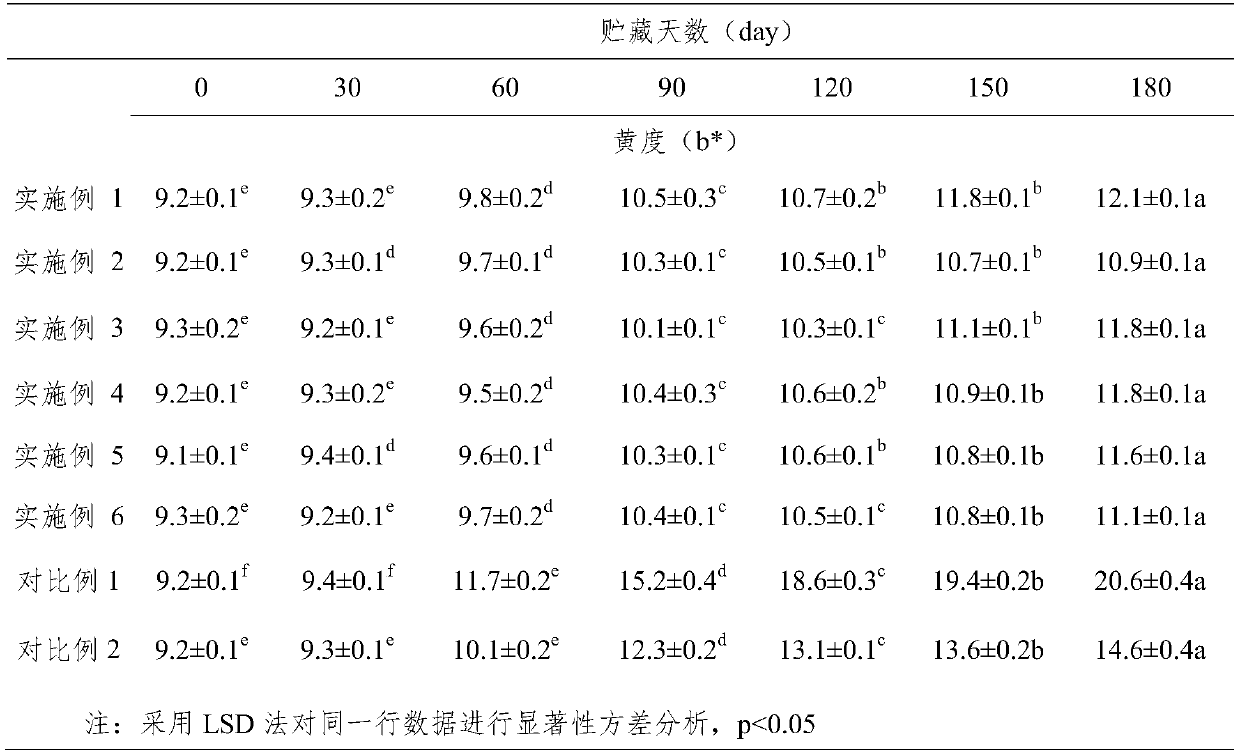

A technology for soaking liquid and soft rice is applied in the preparation of high-quality instant soft rice. The field of instant rice soaking liquid can solve problems such as yellowing during storage, and achieve the effects of reducing soaking process, inhibiting yellowing phenomenon, and enhancing the aroma of rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the instant rice soaking liquid of the present invention is formed by adding Brevibacterium flavum into rice washing water and fermenting. It can also be prepared by fermenting rice washing water with other kinds of microorganisms.

[0041] The preparation method of the instant rice soaking liquid of the present invention is preferably as follows: mixing rice washing water and Brevibacterium flavum at a weight ratio of 1800:1 to 2200:1; Stir once every 10-15 hours; finish the fermentation when the pH of the rice washing water is 4.8-5.0 to obtain a fermentation liquid; filter the fermentation liquid with a filter cloth of 100-140 mesh to obtain a soaking liquid.

[0042] Preferably, the content of L-tyrosine in the soaking solution is set to be ≥0.1 mg / mL.

[0043] The preparation method of instant soft rice of the present invention, it comprises the following steps:

[0044]S1: wash the rice at least once, separate the rice and collect the r...

Embodiment 1

[0055] The preparation method of instant soft rice, its step is:

[0056] S1: Preparation of raw rice: pearl rice and jasmine rice are used as raw rice, mixed evenly at a mass ratio of 9:1, to ensure that the amylose content of the rice is between 15% and the broken rice rate is 20%.

[0057] S2: Washing of raw rice: Lift the rice to the rice warehouse, use a rice washing machine to wash the rice twice within 5 minutes, drain the washed rice quickly, and collect the rice washing water.

[0058] S3: Preparation of soaking solution: add food-grade Brevibacterium flavum to the rice washing water at a weight ratio of 1800:1, then place the rice washing water in a cool and ventilated place at 23°C for open-air fermentation, and stir once every 10 hours , until the pH of the fermented liquid is 4.8, the L-tyrosine content is 0.1 mg / mL, boil and heat for less than 5 minutes to end the fermentation, and filter the fermented liquid with a 100-mesh filter cloth, the fermentation time is...

Embodiment 2

[0064] The preparation method of instant soft rice, its step is:

[0065] S1: Preparation of raw rice: Pearl rice and jasmine rice are used as raw rice, mixed evenly at a mass ratio of 9:1, to ensure that the amylose content of the rice is 20%, and the broken rice rate is 15%.

[0066] S2: Washing of raw rice: Lift the rice into the rice warehouse, use the rice washing machine to wash the rice twice within 5 minutes, drain the washed rice quickly, and collect the rice washing water.

[0067] S3: Preparation of soaking solution: add food-grade Brevibacterium flavum to the rice washing water at a weight ratio of 2200:1, then place the rice washing water in a cool and ventilated place at 25°C for open-air fermentation, and stir once every 15 hours , until the pH of the fermentation broth=5.0, the L-tyrosine content is 0.3mg / mL, the fermentation time is about 30h, and the fermentation is completed by boiling and heating for less than 5 minutes, and the fermentation broth is filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com