A high-pressure duster for food production with the function of cleaning and dehumidification

A high-pressure spraying and functional technology, applied in the fields of dough processing, food science, spraying device, etc., can solve the problems of affecting food hygiene and safety, the inner wall of the spray pipe is wet, and the flour absorbs moisture and sticks, so as to achieve a clean powder spraying process and avoid problems. The effect of remaining inside and eliminating the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

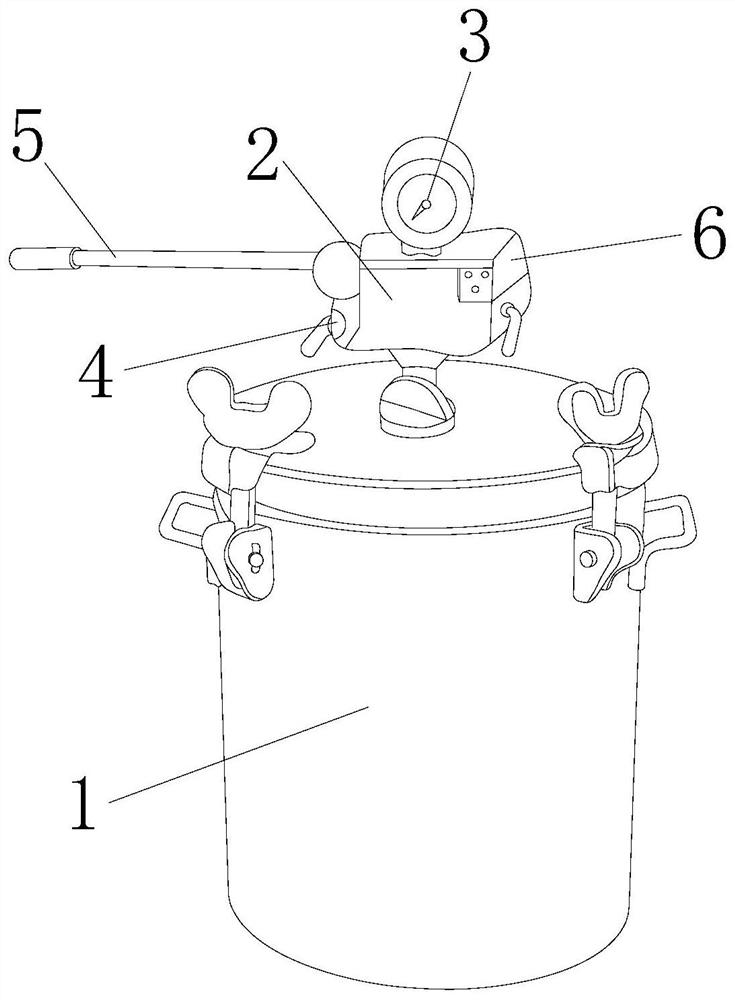

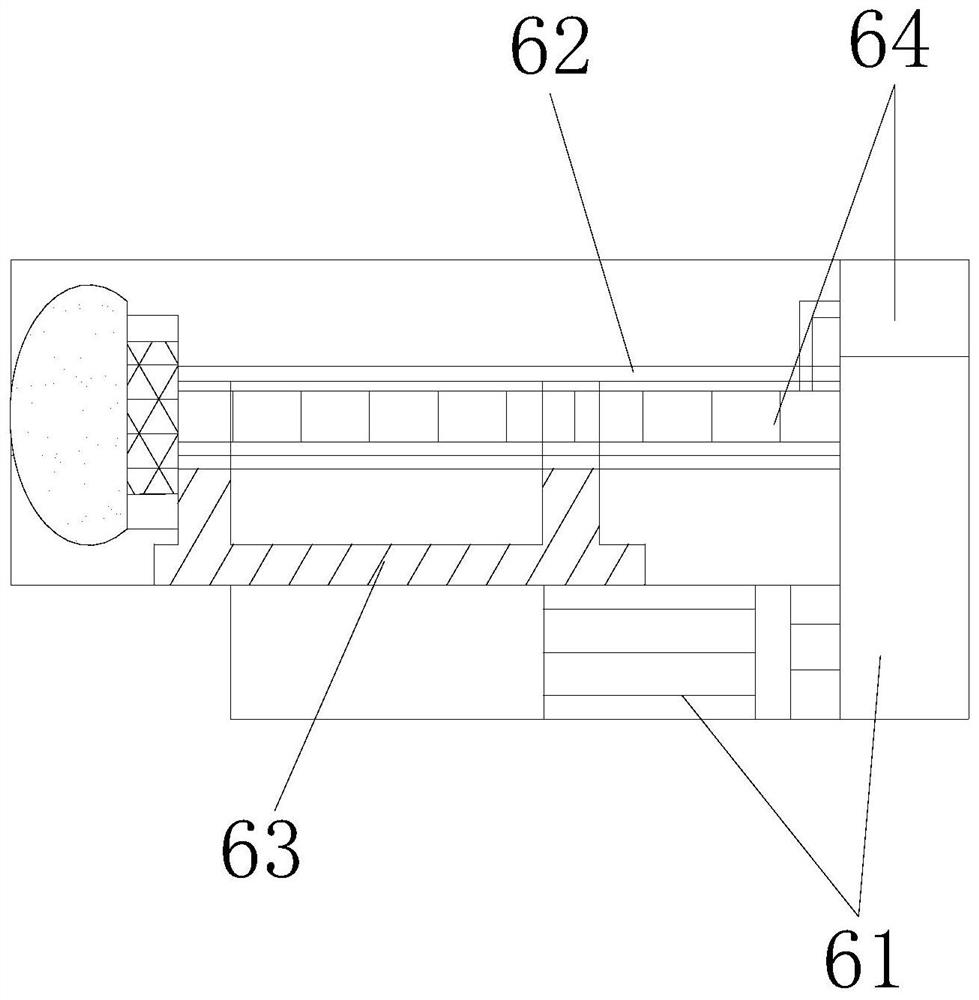

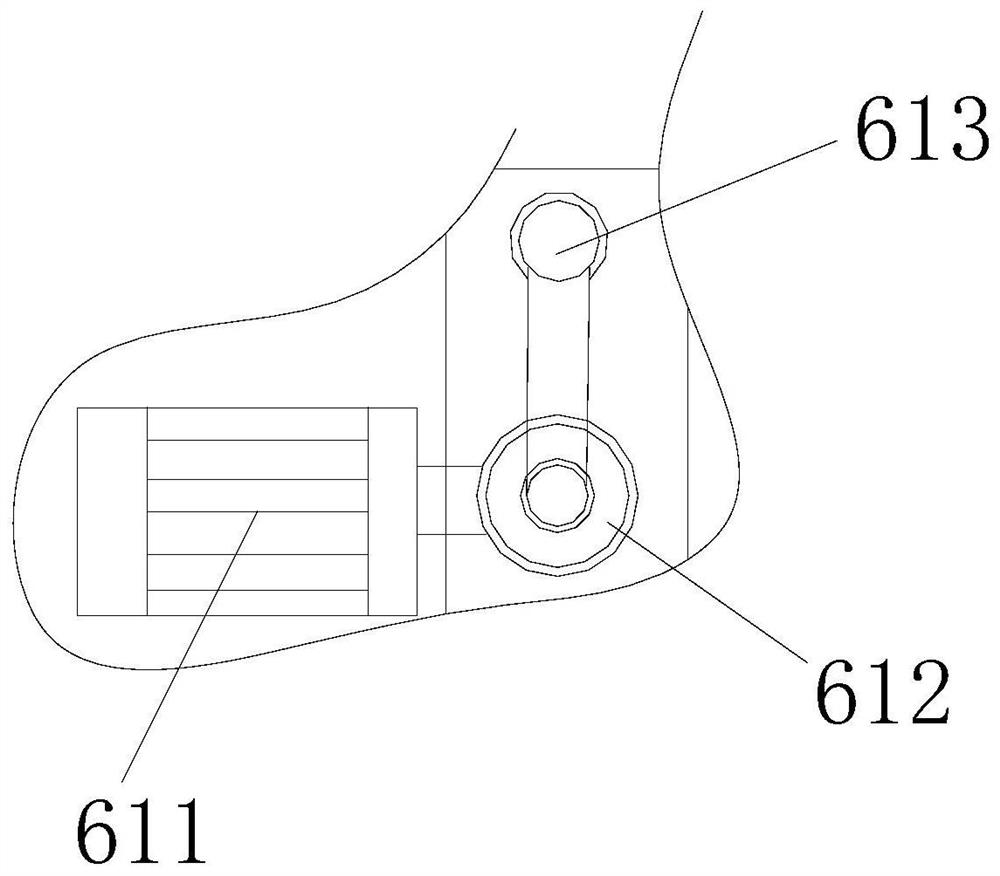

[0028] see Figure 1-Figure 2 , the present invention provides a technical solution: a high-pressure duster for food production with the function of cleaning and dehumidifying. . Drying and cleaning device 6, the top surface of the flour pressure storage tank 1 is welded to the bottom surface of the pulse control box 2, the top of the pulse control box 2 is fixed with a barometer 3, and the side surface is also provided with an air source valve 4 With the nozzle 5, the nozzle 5 is fixedly installed above the air source valve 4, the inside of the pulse control box 2 is provided with a drying cleaning device 6, and the drying cleaning device 6 and the nozzle 5 are on the same horizontal line; The drying and cleaning device 6 is composed of a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com