Bevel gear and transmission mechanism with bevel gear

A technology of helical gears and gear shafts is applied in the field of helical gears and transmission mechanisms with the helical gears, which can solve the problems of inability to guarantee the meshing rigidity requirements, the decline of the use performance of the helical gears, the failure of aviation equipment, etc. Improved usability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

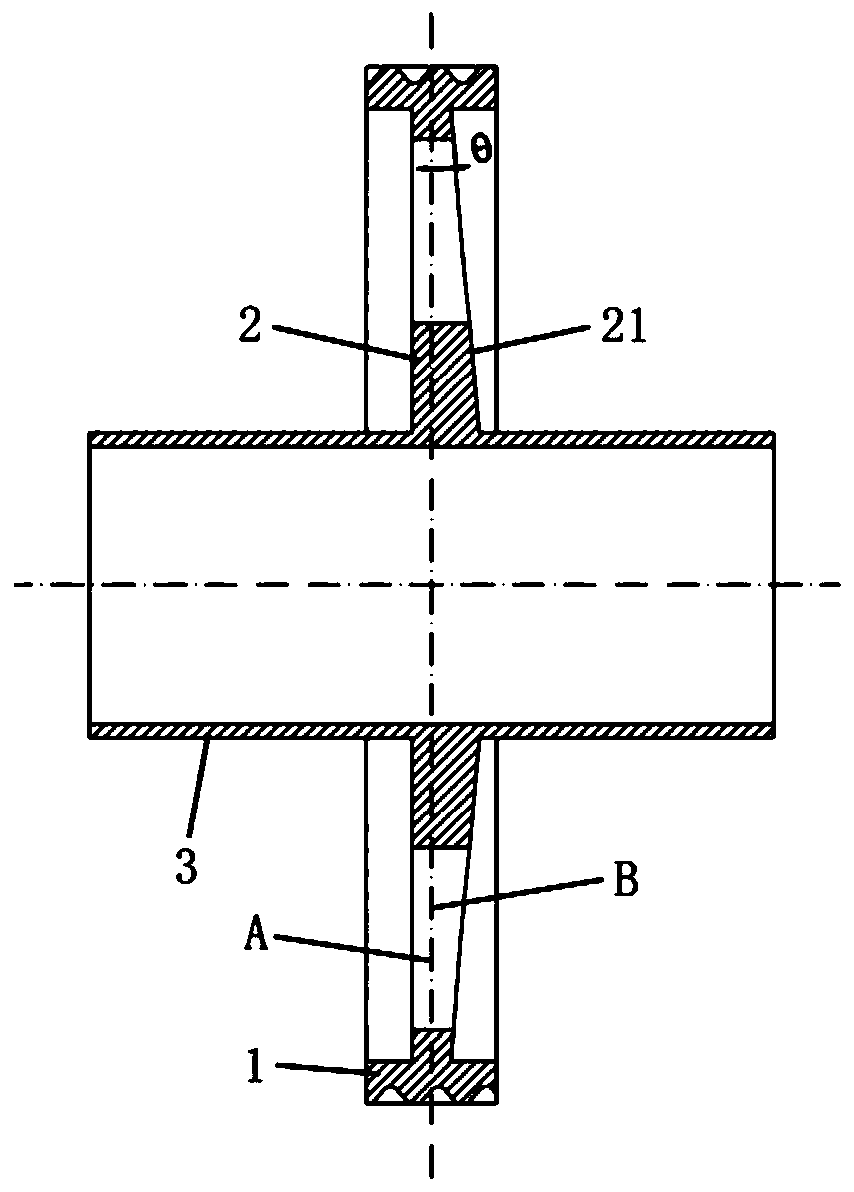

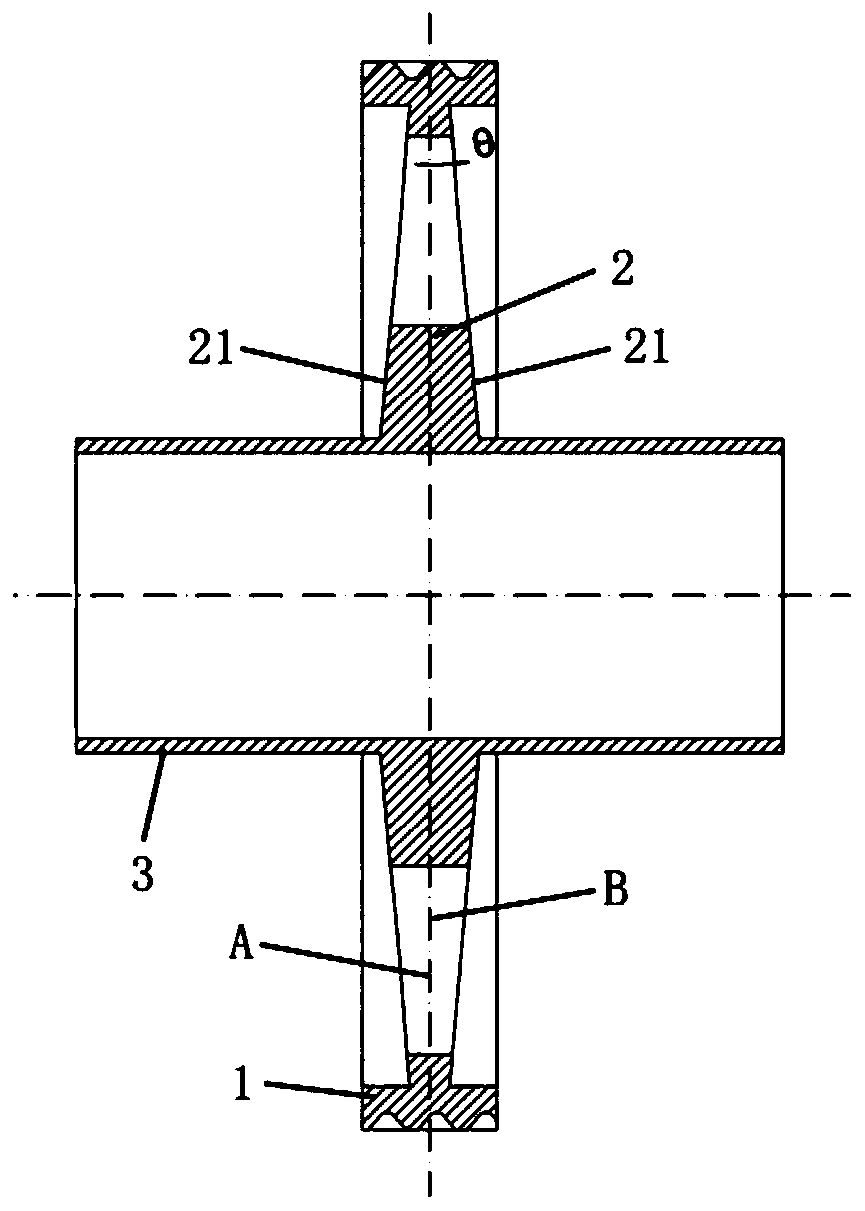

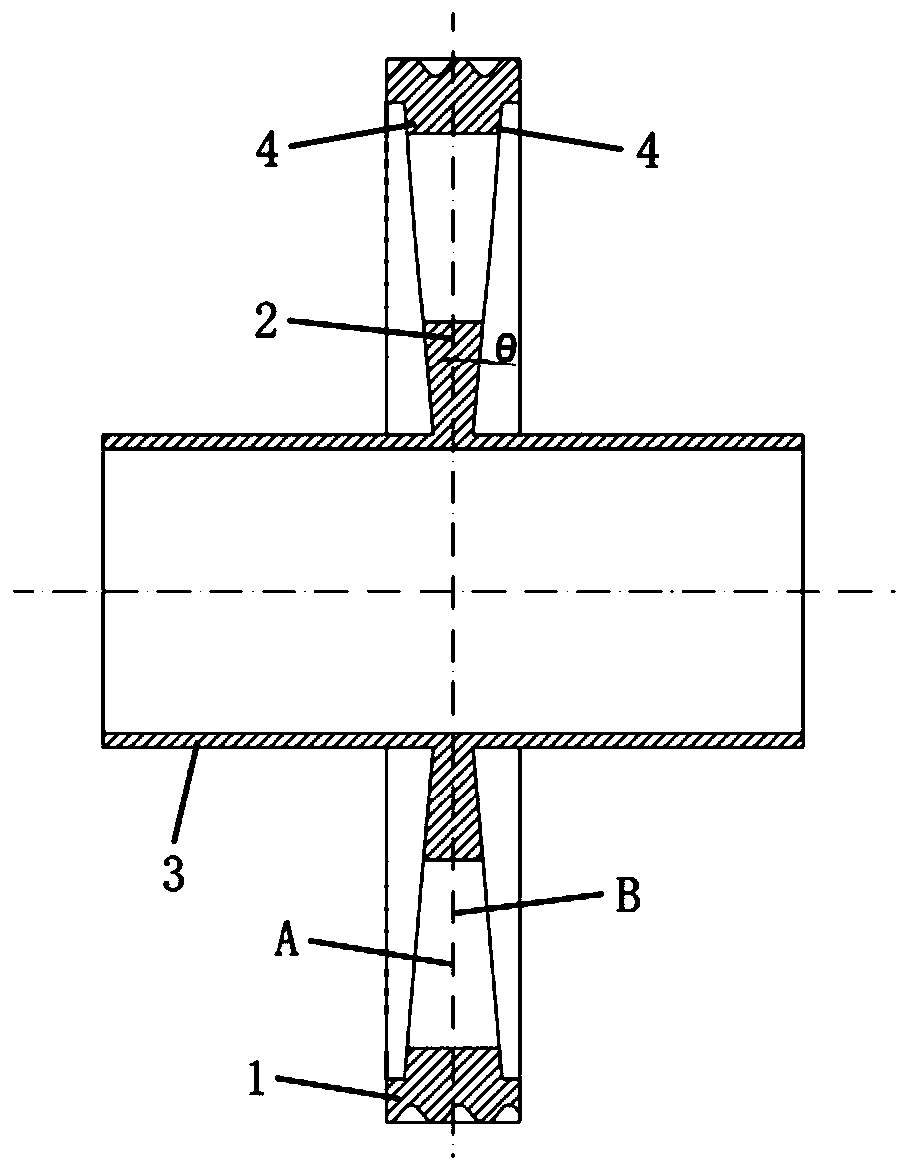

[0038] Such as Figure 18 with Figure 19 As shown, the helical gear of this embodiment includes a ring gear 1, a web 2 and a gear shaft 3 with a number of gear teeth 11. The gear shaft 3 penetrates the web 2 and is connected to the web 2, and one side of the web 2 is provided There is a reinforcement 21; a plane A perpendicular to the axis of the gear shaft 3 and bisecting the web 2 and a plane B perpendicular to the axis of the gear shaft 3 and bisecting each gear tooth 11, plane A relative to plane B in the axial direction of the gear shaft 3 Offset by a set distance, and the plane A and the reinforcement 21 are located on the same side of the plane B. The helical gear is provided with a reinforcement 21 on one side of the web 2, and at the same time, the plane A perpendicular to the axis of the gear shaft 3 and bisecting the web 2 is in the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com