Beam pumping unit-used direct-drive permanent magnet synchronous motor

A permanent magnet synchronous pumping unit technology, which is applied to synchronous motors, electromechanical devices, electric components, etc. Service life and other issues, to achieve compact layout, improve integrity, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

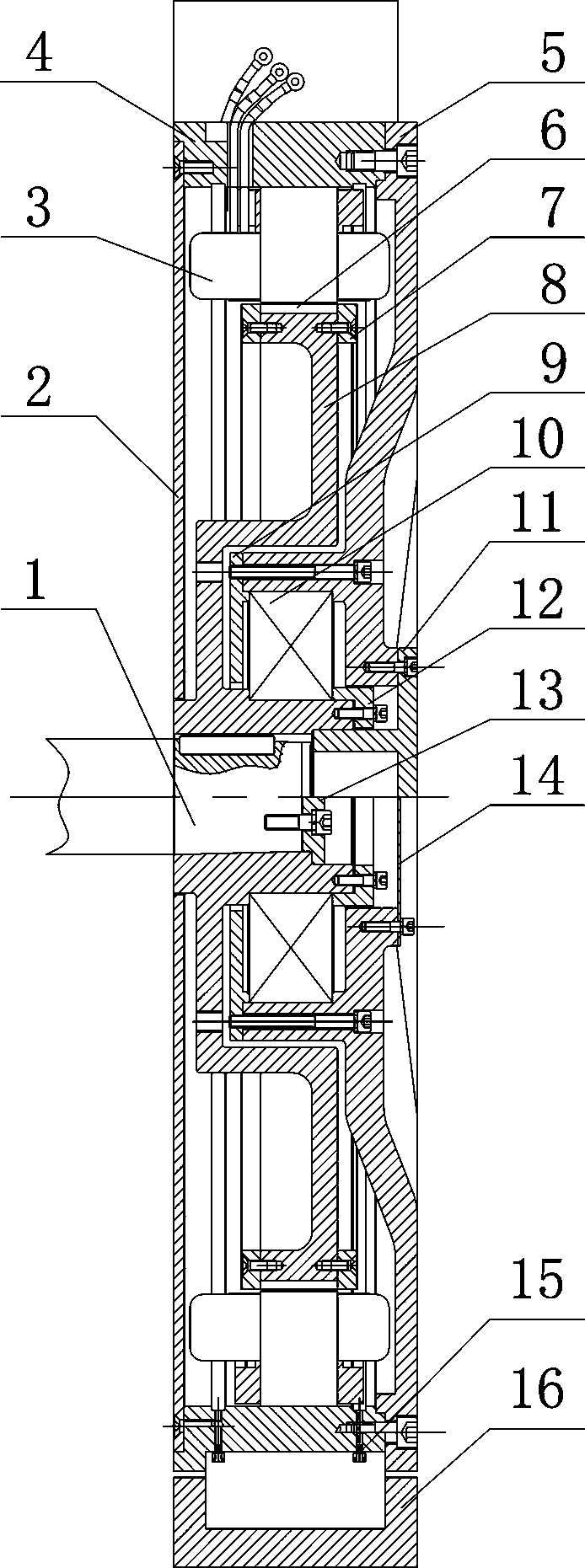

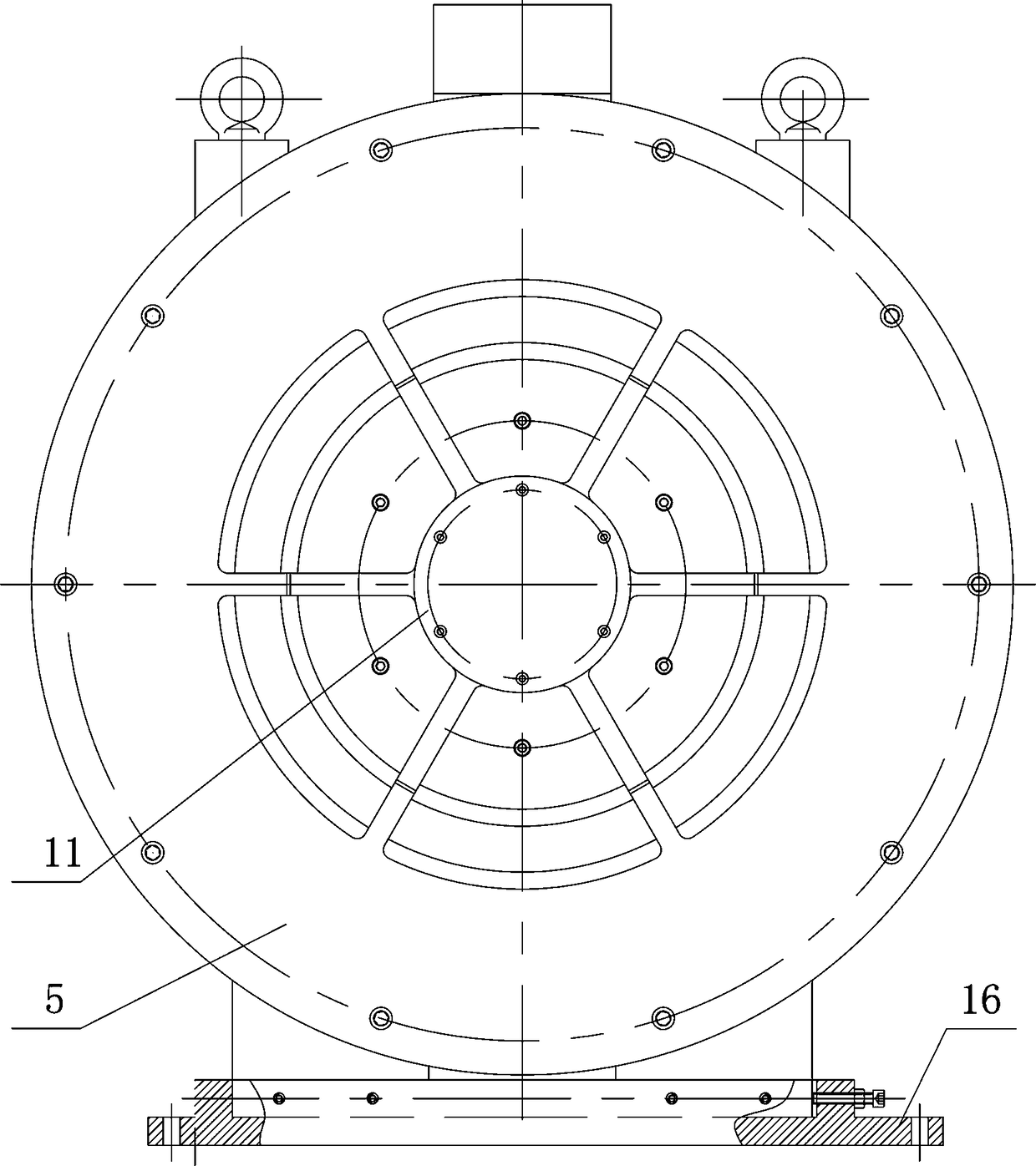

[0015] according to Figure 1~2 The specific structure of the present invention will be described in detail. The direct drive permanent magnet synchronous motor for the beam pumping unit includes a base 16 fixed on the platform of the beam pumping unit, a left end cover 2 and a right end cover 5 assembled on the stator assembly, the stator assembly and the direct reducer The rotor assembly and other components connected to the input shaft 1. The stator assembly is composed of a stator wire package 3 press-fitted in the casing 4. Drainage grooves are arranged on both sides of the stator wire package 3, and a drainage respirator 15 is connected to the bottom of the casing 4 at the drainage groove. The rotor sleeve 8 with the permanent magnet 6 attached to the surface of the rotor assembly is assembled in the shaft hole of the right end cover 5 of the casing 4 through the bearing 10, and the permanent magnet 6 is attached to the rotor sleeve by using the end plates 7 fixed on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com