A planetary gear drive electric servo screw press with helical teeth and few tooth differences

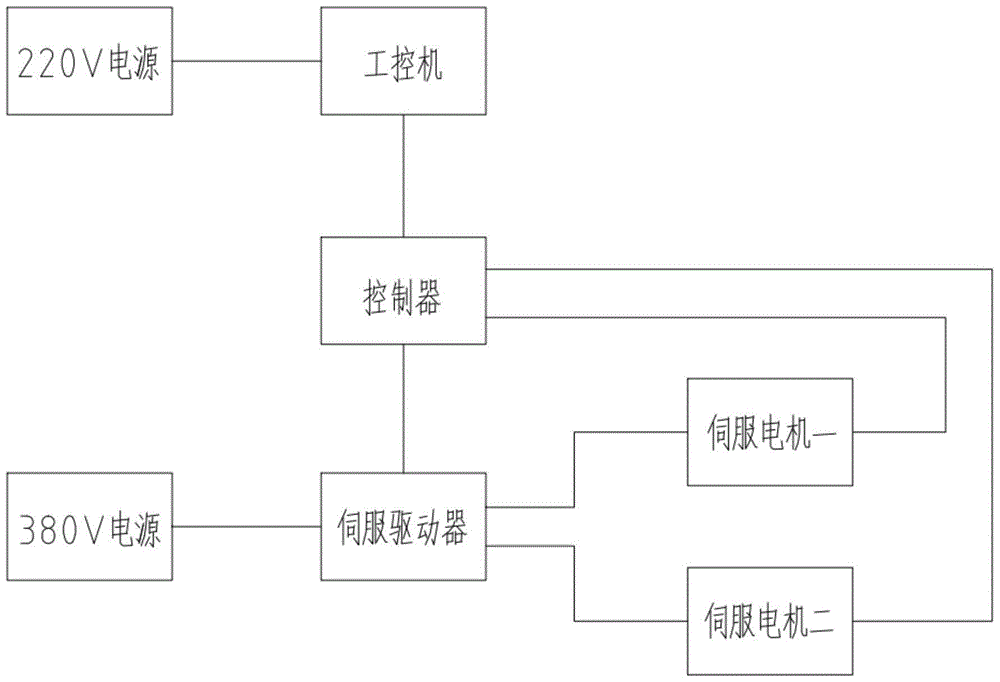

A planetary and screw press technology with less tooth difference, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problem that the servo performance and power performance of the direct drive motor are too high, it is difficult to meet the market demand of screw presses, and the life of the motor It can reduce the impact of the power grid, improve the partial load, and reduce the power demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be explained in detail below with reference to the accompanying drawings and embodiments.

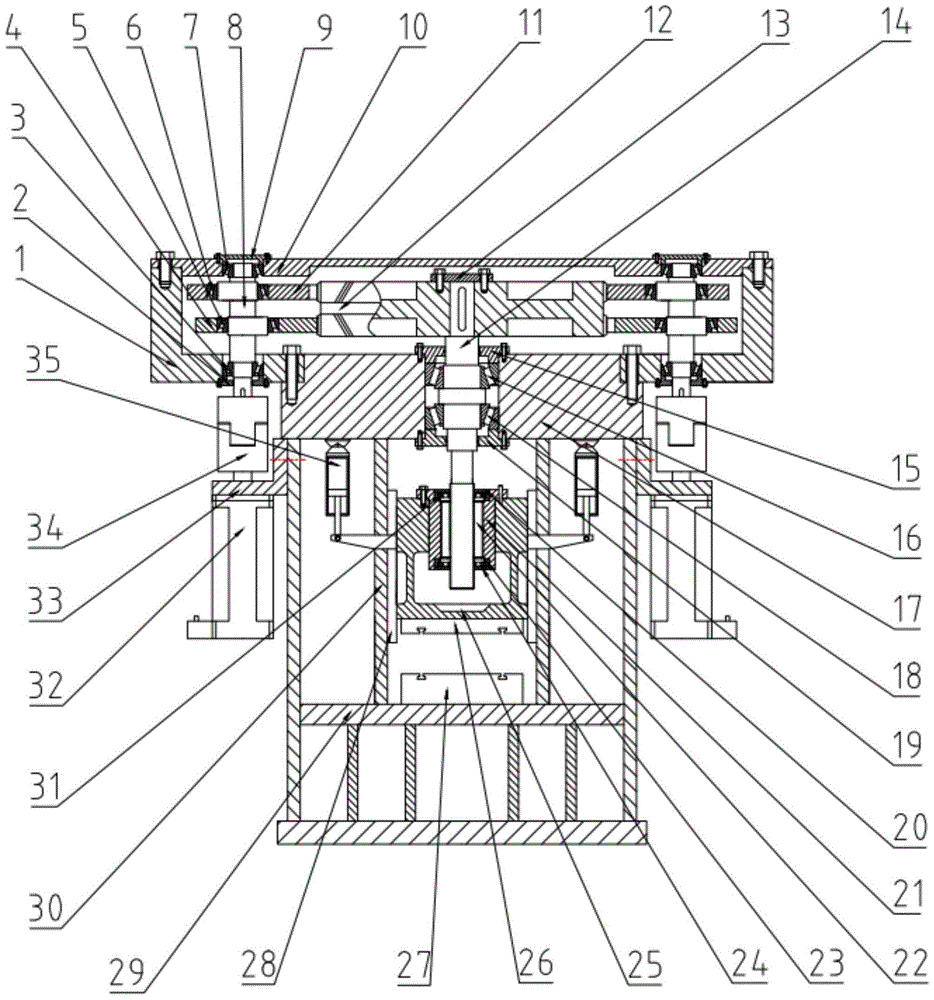

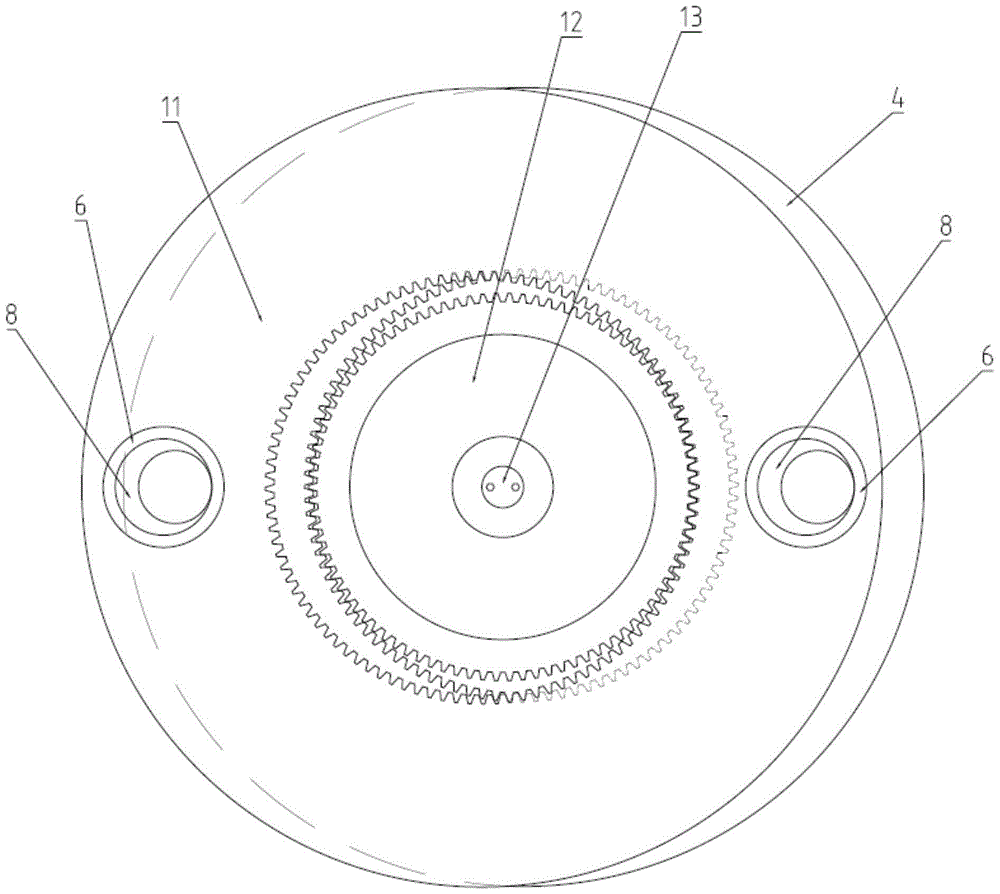

[0014] refer to figure 1 with figure 2 , an electric servo screw press with helical teeth and less tooth difference planetary gear transmission, including a fuselage 30, the bottom of the fuselage 30 is connected to the base 29, the upper part of the fuselage 30 is connected to the upper top plate 17, and two servo motors 32 pass through the motor base 33 Installed on two sides of the fuselage 30 respectively, the output shaft of the servo motor 32 is connected with the driving crankshaft 8 of the planetary gear transmission part of the helical tooth and small tooth difference through the coupling 34, and one end of the driving crankshaft 8 passes through the first bearing 3 and the first cover plate 2 Supported on the reducer casing 1, the reducer casing 1 is fixed on the upper top plate 17 by screws; the other end of the driving crankshaft 8 is supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com