Pull rod structure for stacker-reclaimer

A technology of tie rod structure and reclaimer, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve problems such as damage, unbalanced load on the upper part of the rotation, belt conveyor deviation, etc., achieve uniform wheel pressure distribution, increase stability, and improve The effect of partial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

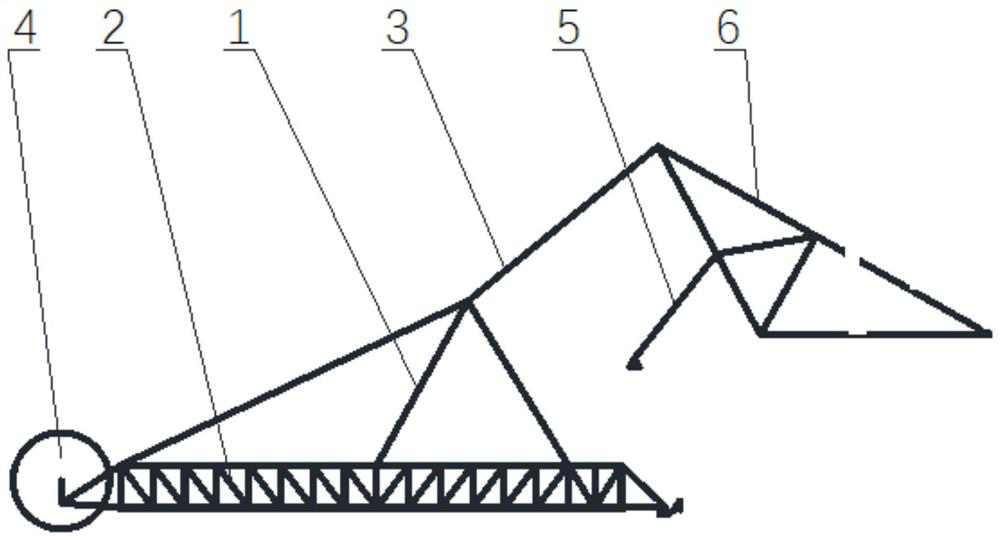

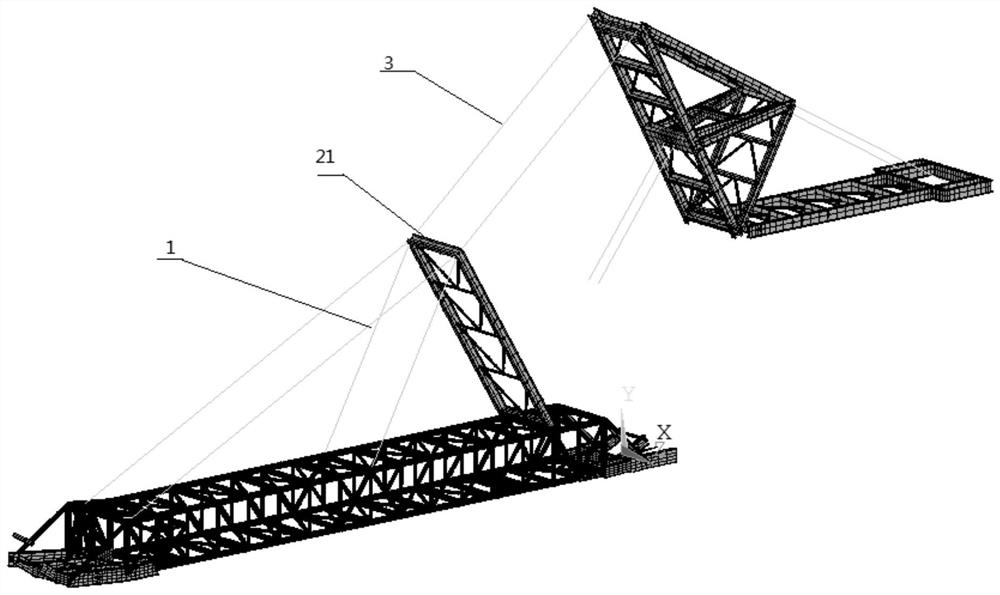

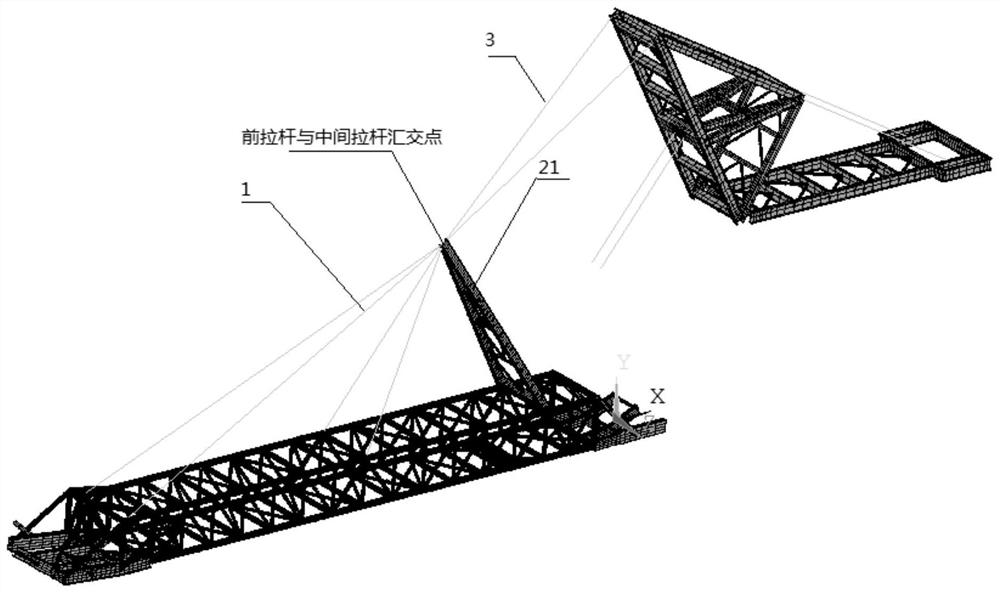

[0021] Such as figure 1 and image 3 As shown, the tie rod structure of the stacker-reclaimer in this embodiment includes at least one pair of front tie rods 1 and a pair of middle tie rods 3, the ends of the front tie rods 1 and the middle tie rods 3 meet at the front arm frame 2 connected to the stacker-reclaimer A pair of struts 21 on one end.

[0022] In this embodiment, 1 pair of front tie rods, 21 pairs of strut rods and 3 pairs of middle tie rods are all in the shape of "A", and the intersection ends of 1 pair of front tie rods, 21 pairs of strut rods and 3 pairs of middle tie rods are sharp corners of "A". .

[0023] In this embodiment, 1 pair of fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com