A deformable straw drainage body and a method of vacuum dewatering and special-shaped pile solidification and reinforcement for silt foundation anti-silting

A technology of silt foundation and drainage body, applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve the problems of limited water permeability of straw drainage body, limited water permeability of drainage body, and high grouting pressure, etc., to achieve Low fluidity requirements, reduced construction difficulty, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

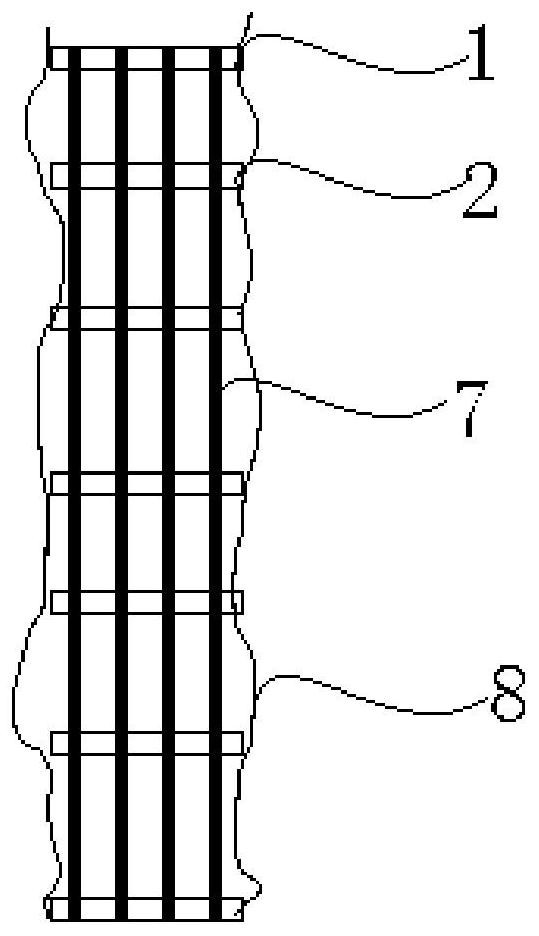

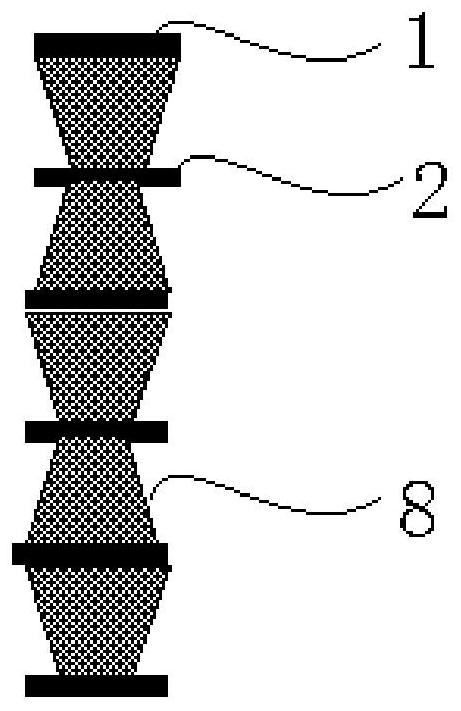

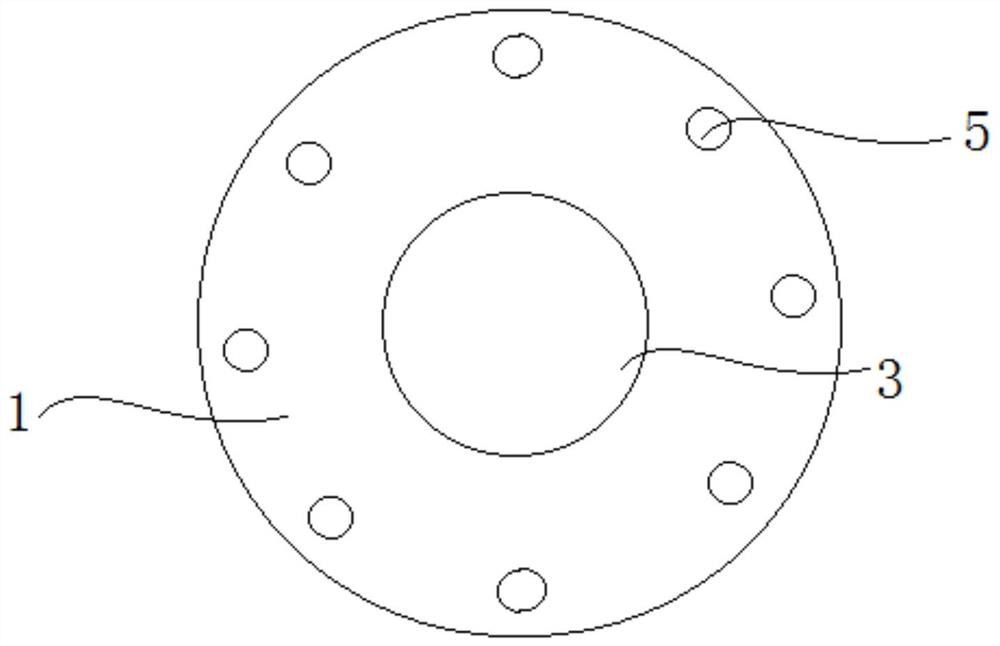

[0041]The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0042] Such as Figure 1-Figure 5 As shown, the present invention includes the following characteristic parts: 1 is a positioning plate, 2 is a sliding plate, 3 is a positioning water hole, 4 is a sliding water hole, 5 is a positioning rope hole, 6 is a sliding groove, 7 is a straw rope, 8 is permeable filter cloth.

[0043] A deformable straw drainage body of the present invention comprises at least two positioning plates arranged coaxially, a sliding plate is arranged between two adjacent positioning plates, and the centers of the sliding plate and the positioning plate are on the same axis;

[0044] The center of the aforementioned positioning plate is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com