Heat pump mixed working medium and application thereof

A mixed working medium and heat pump technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor high-temperature heating performance and inability to meet the temperature requirements of heating hot water, etc., and achieve extended life and suction specific volume Small, GWP reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

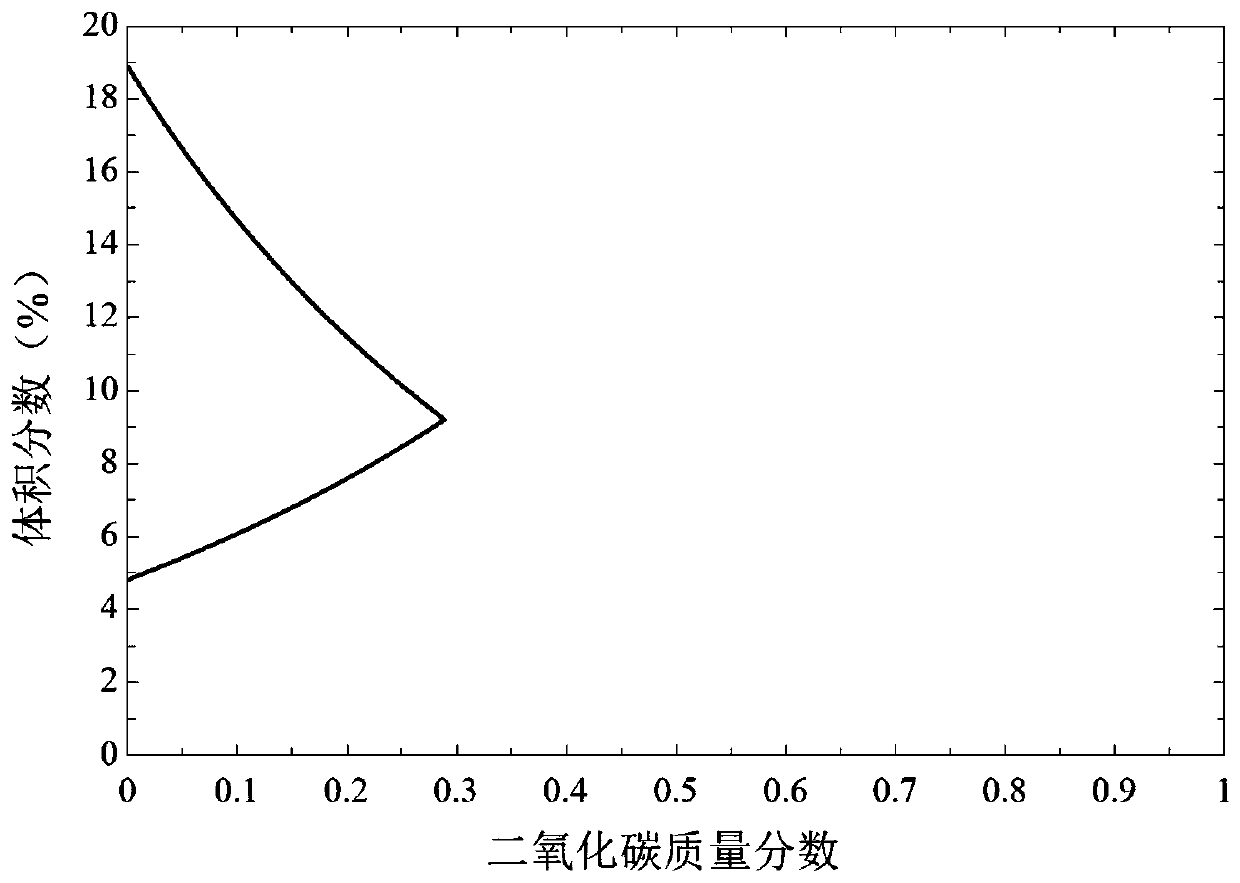

Image

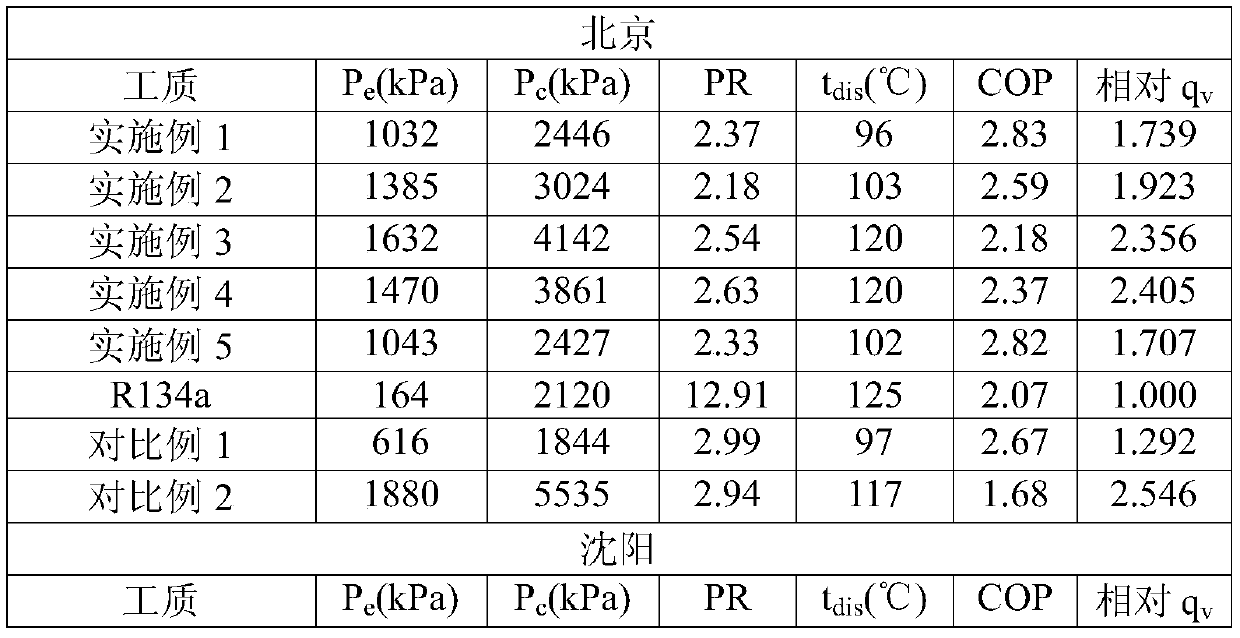

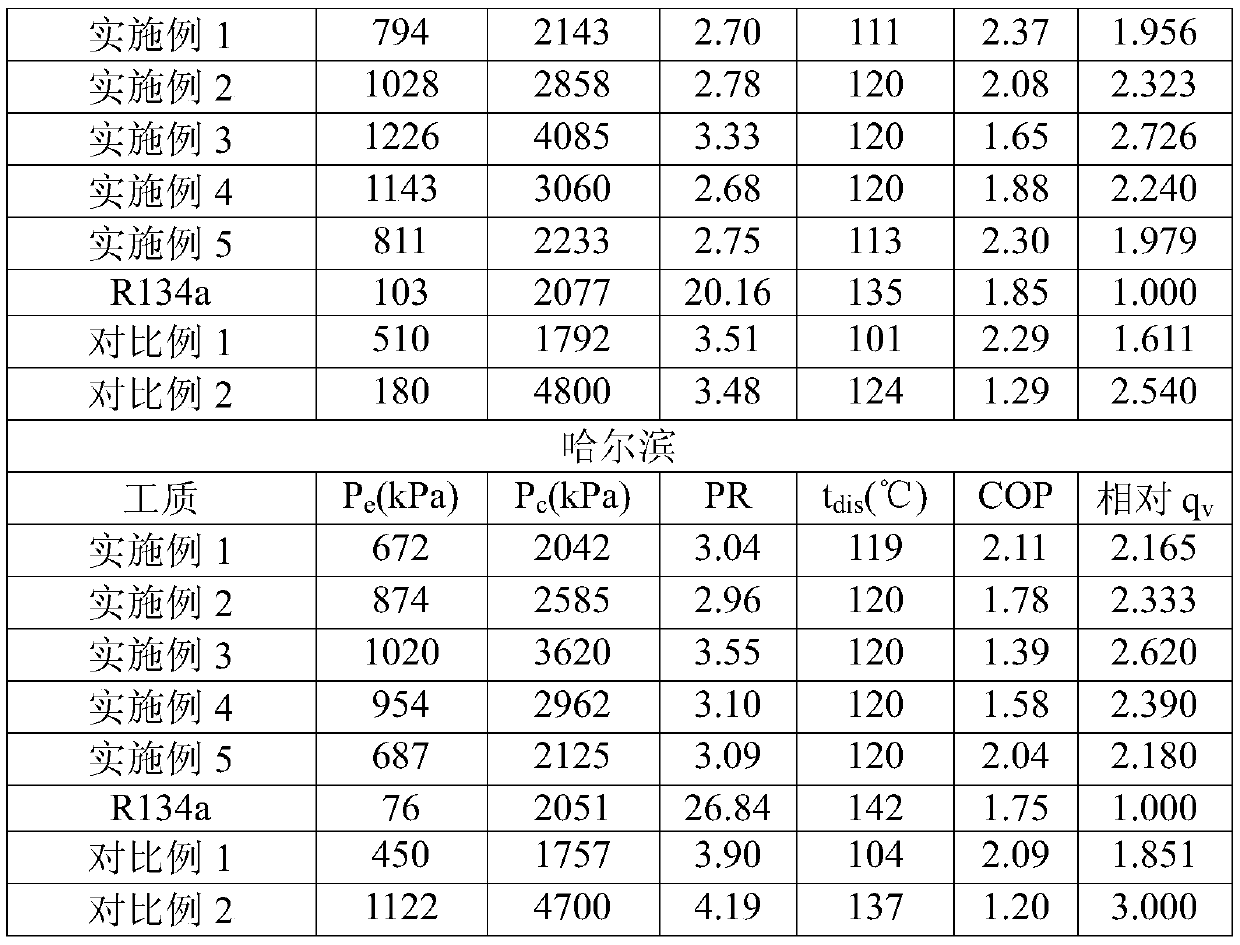

Examples

Embodiment 1

[0034] Physically mix cis-1,3,3,3-tetrafluoropropene and carbon dioxide in a liquid phase at a mass percentage of 55:45 to obtain a heat pump mixed working fluid.

Embodiment 2

[0036] Physically mix cis-1,3,3,3-tetrafluoropropene and carbon dioxide in a liquid phase at a mass percentage of 45:55 to obtain a heat pump mixed working fluid.

Embodiment 3

[0038] Physically mix cis-1,3,3,3-tetrafluoropropene and carbon dioxide in a liquid phase at a mass percentage of 35:65 to obtain a heat pump mixed working fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com