Nickel-catalyzed nano-magnesium negative electrode material for magnesium-lithium double-salt battery and preparation method of negative electrode material

A negative electrode material and nickel catalysis technology, which is applied in the field of nickel catalyzed nano-magnesium negative electrode material and preparation, can solve the problems of restricting the development of magnesium-lithium double-salt batteries and reducing the kinetic process of battery charge and discharge, so as to improve the activity and ion diffusion kinetics. properties, improved kinetic properties, increased activity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

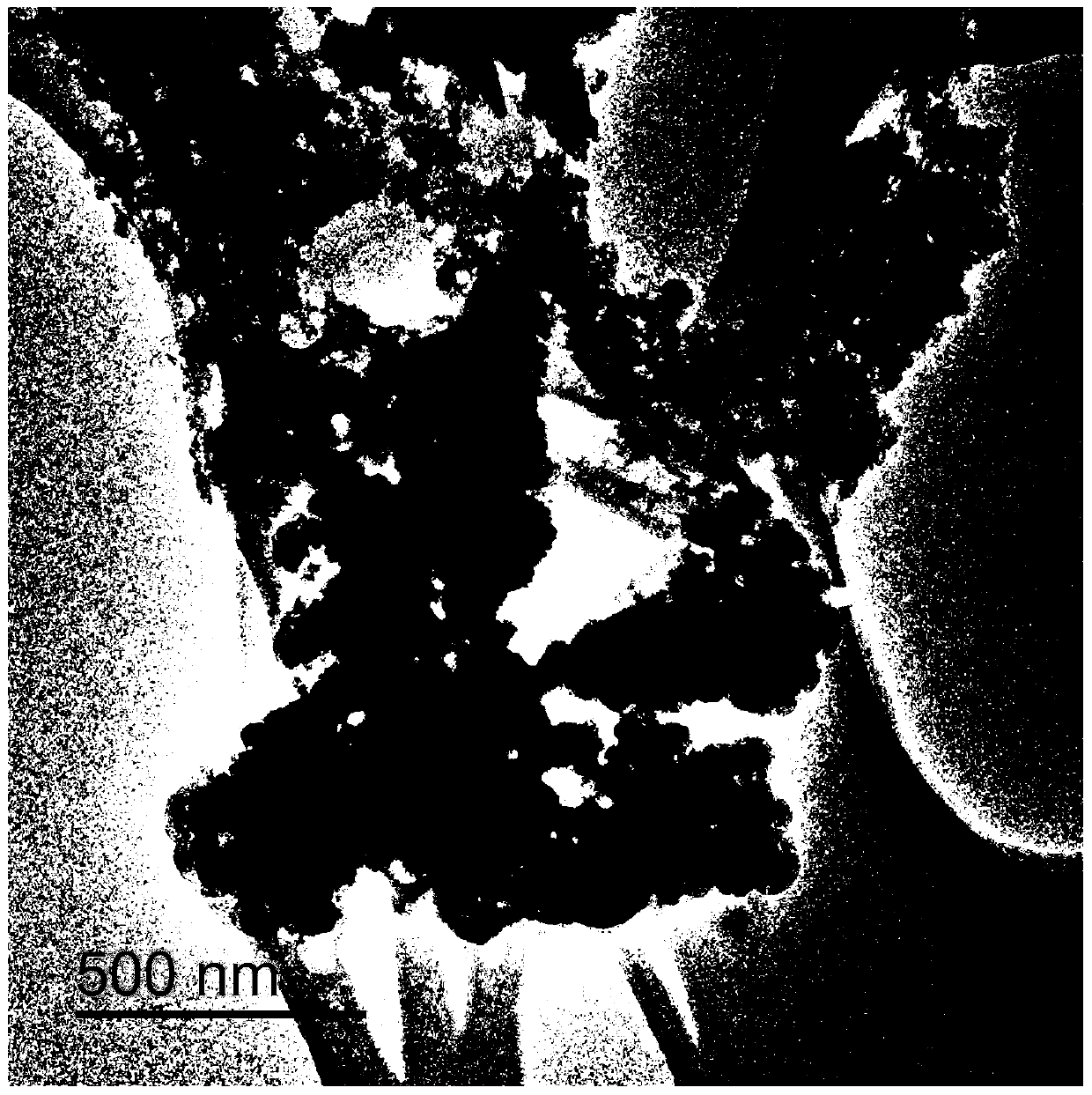

Image

Examples

Embodiment 1

[0034] A method for preparing a nickel-catalyzed nano-magnesium negative electrode for a magnesium-lithium double-salt battery, comprising the following steps;

[0035] Step 1, preparation of Mg-Ni nano alloy particles:

[0036] 1) 1g anhydrous MgCl 2 and 0.08g NiCl 2 Add it into 160ml of tetrahydrofuran (THF), and stir the mixed solution on a magnetic stirrer at 60°C for 1h to obtain a small amount of sky blue solution; add 4g of naphthalene and 0.2g of lithium flakes to 40ml of THF, and stir vigorously on a magnetic stirrer for 2h to obtain Dark green (black) naphthyl lithium solution.

[0037] 2) MgCl 2 and NiCl 2 The mixed solution was added dropwise to the naphthyllithium solution and stirred for 24h. 1) and 2) are both completed in an ultra-purified glove box, and the water and oxygen content in the modified environment are both ≤0.1PPM;

[0038] 3) The product is subjected to centrifugation at a speed of 12,000. Wash three times with THF after centrifugation.

...

Embodiment 2

[0049] A method for preparing a negative electrode material for a magnesium-lithium double-salt battery, comprising the following steps;

[0050] Step 1, preparation of Mg-Ni nano alloy particles:

[0051] 1) 1.52g anhydrous MgCl 2 and 0.0932g NiCl 2 Add it to 160ml of tetrahydrofuran (THF), and stir the mixed solution on a magnetic stirrer at 65°C for 1h to obtain a small amount of sky blue solution; add 4.3g of naphthalene and 0.235g of lithium flakes to 40ml of THF, and stir vigorously on a magnetic stirrer for 2h. A dark green (black) naphthyllithium solution was obtained.

[0052] 2) MgCl 2 and NiCl 2 The mixed solution was added dropwise to the naphthyllithium solution and stirred for 24h. 1) and 2) are both completed in an ultra-purified glove box, and the water and oxygen content in the modified environment are both ≤0.1PPM;

[0053]3) The product is subjected to centrifugation at a speed of 12,000. Wash three times with THF after centrifugation.

[0054] 4) Th...

Embodiment 3

[0064] A method for preparing a negative electrode material for a magnesium-lithium double-salt battery, comprising the following steps;

[0065] Step 1, preparation of Mg-Ni nano alloy particles:

[0066] 1) 2g anhydrous MgCl 2 and 0.1g NiCl 2 Add it into 160ml of tetrahydrofuran (THF), and stir the mixed solution on a magnetic stirrer at 70°C for 1h to obtain a small amount of sky blue solution; add 5g of naphthalene and 0.3g of lithium flakes to 40ml of THF, and stir vigorously on a magnetic stirrer for 2h to obtain Dark green (black) naphthyl lithium solution.

[0067] 2) MgCl 2 and NiCl 2 The mixed solution was added dropwise to the naphthyllithium solution and stirred for 24h. 1) and 2) are both completed in an ultra-purified glove box, and the water and oxygen content in the modified environment are both ≤0.1PPM;

[0068] 3) The product is subjected to centrifugation at a speed of 12,000. Wash three times with THF after centrifugation.

[0069] 4) The samples af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com