Lithium battery diaphragm and preparation method thereof

A lithium battery diaphragm and film surface technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of low lithium ion migration number and low ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Based on the same inventive concept, an embodiment of the present invention also provides a method for preparing a lithium battery separator, the method comprising:

[0037] Add the inorganic oxide precursor to the alumina dispersion, stir for 2-4 hours, add a binder and a second organic additive, and continue stirring for 3-4 hours to obtain a core-shell structure inorganic oxide slurry;

[0038] The inorganic oxide slurry with the core-shell structure is coated on the surface of the porous polyolefin base film, and dried to prepare a lithium battery diaphragm.

[0039] In the present application, in parts by weight, the alumina dispersion is 80-90 parts, the inorganic oxide precursor is 0.4-5 parts, the binder is 3-6 parts, and the organic additive Makes 3-4 servings.

[0040] In the present application, the adhesive is a polyacrylic adhesive, including any one of polymethylacrylate, polyethylacrylate, and polyacrylamide, and the second organic additive includes a we...

Embodiment 1

[0044] (1) Calculated by weight, take 45 parts of micron alumina particles, mix 0.398 parts of polyoxyethylene neutral surfactant with 54.602 parts of deionized water, pre-disperse on a mechanical mixer for 10 minutes, and then grind on a grinder for 30 minutes , filtered and iron removed to obtain an alumina dispersion.

[0045] (2) Take 88.88 parts of alumina dispersion, add 4g ethanol, 0.8g tetraethyl orthosilicate, stir for 2-4 hours, add 6 parts of polyacrylic acid, 3.7 parts of polyoxyethylene neutral surfactant, stir for 3- After 4 hours, a coating slurry of a core-shell structure oxide was obtained.

[0046] (3) Apply the coating slurry to the surface of a 12-micron PE diaphragm by scraping, and dry it at 60 degrees Celsius for 1 hour to obtain a single-sided coated SiO 2 @Al 2 o 3 / PE separator, the thickness of the inorganic layer is 4 microns.

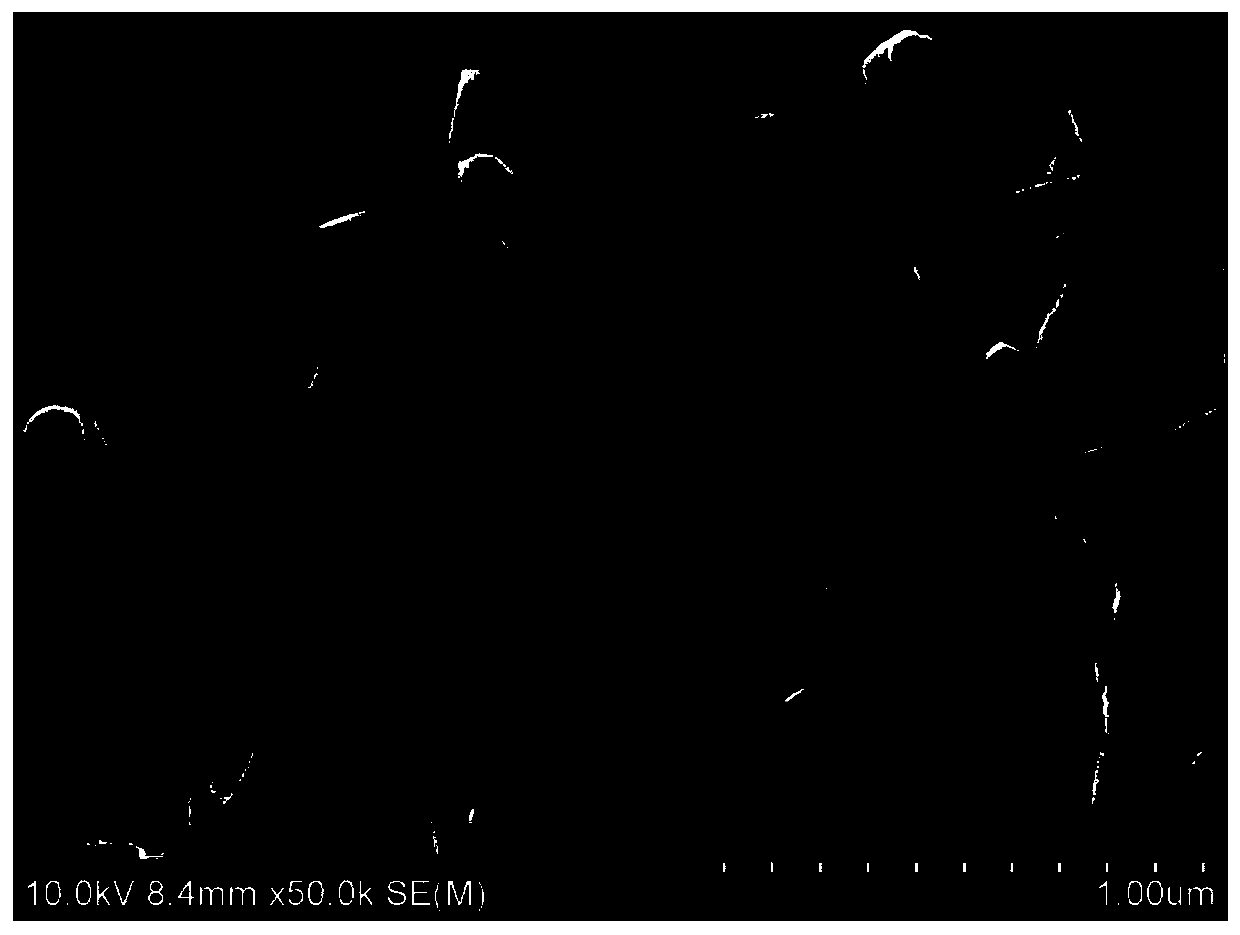

[0047]Coat one side with SiO 2 @Al 2 o 3 / PE diaphragm for morphology characterization, air permeability, electrica...

Embodiment 2

[0049] (1) Calculated by weight, take 45 parts of micron alumina particles, mix 0.398 parts of polyoxyethylene neutral surfactant with 54.602 parts of deionized water, pre-disperse on a mechanical mixer for 10 minutes, and then grind on a grinder for 30 minutes , filtered and iron removed to obtain an alumina dispersion.

[0050] (2) Take 88.88 parts of alumina dispersion, add 4g ethanol, 1.4g tetraethyl orthosilicate, stir for 2-4 hours, add 6 parts of polyacrylic acid, 3.7 parts of polyoxyethylene neutral surfactant, stir for 3- After 4 hours, a coating slurry of a core-shell structure oxide was obtained.

[0051] (3) Coat the coating slurry on the surface of a 12-micron PE diaphragm by scrape coating, and dry it at 60 degrees Celsius for 1 hour to obtain a single-sided coated SiO 2 @Al 2 o 3 / PE separator, the thickness of the inorganic layer is 4 microns.

[0052] Coat one side with SiO 2 @Al 2 o 3 / PE diaphragm for morphology characterization, air permeability, ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com