A tunnel bottom plate lining concrete temperature crack control anti-cracking K value design method

A technology of concrete temperature and design method, applied in the direction of calculation, instrumentation, electrical digital data processing, etc., can solve the problems of large error of strong constraint method, artificiality of coefficient value, no calculation and analysis of temperature stress, etc., and achieve small calculation error , Calculation formula simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

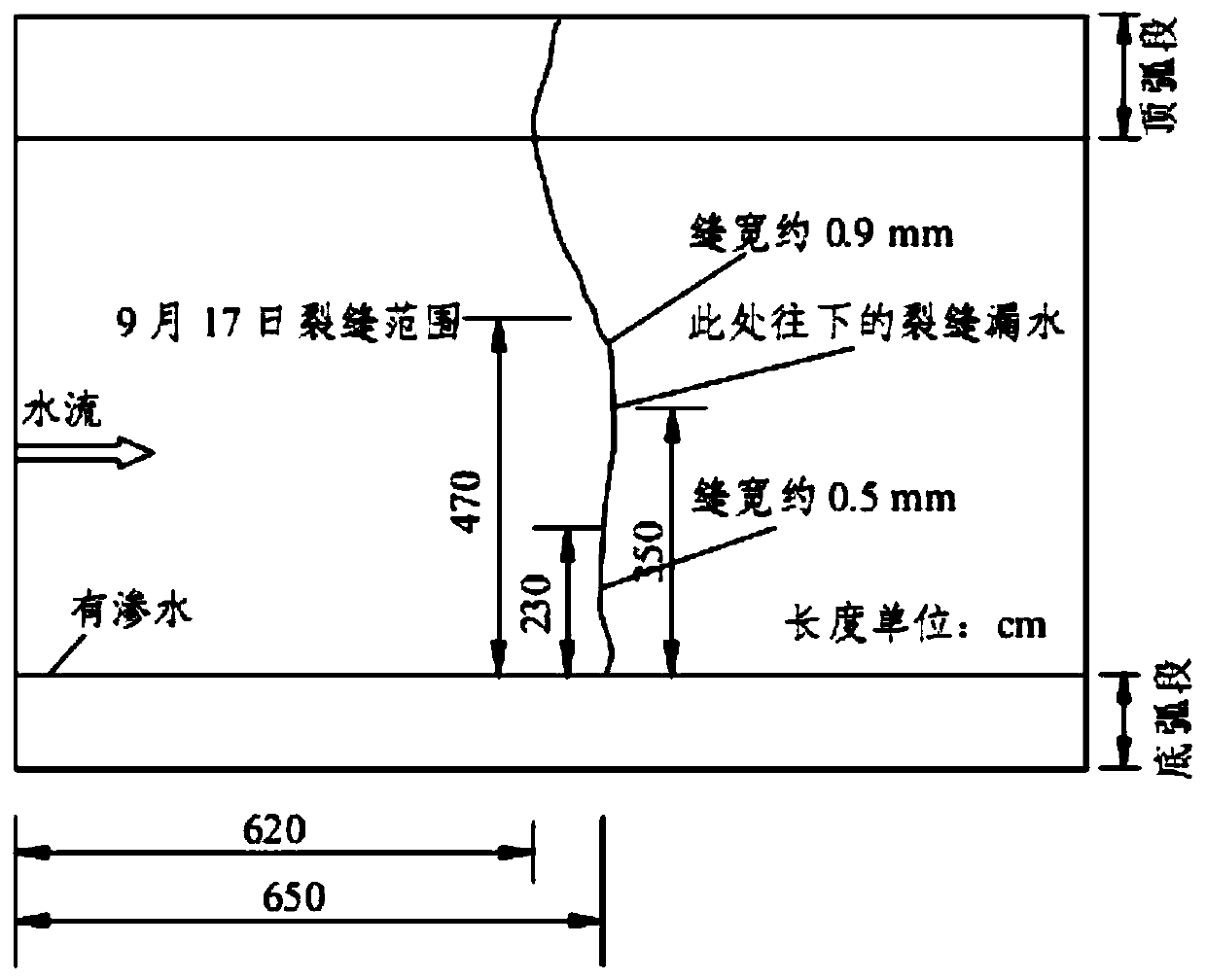

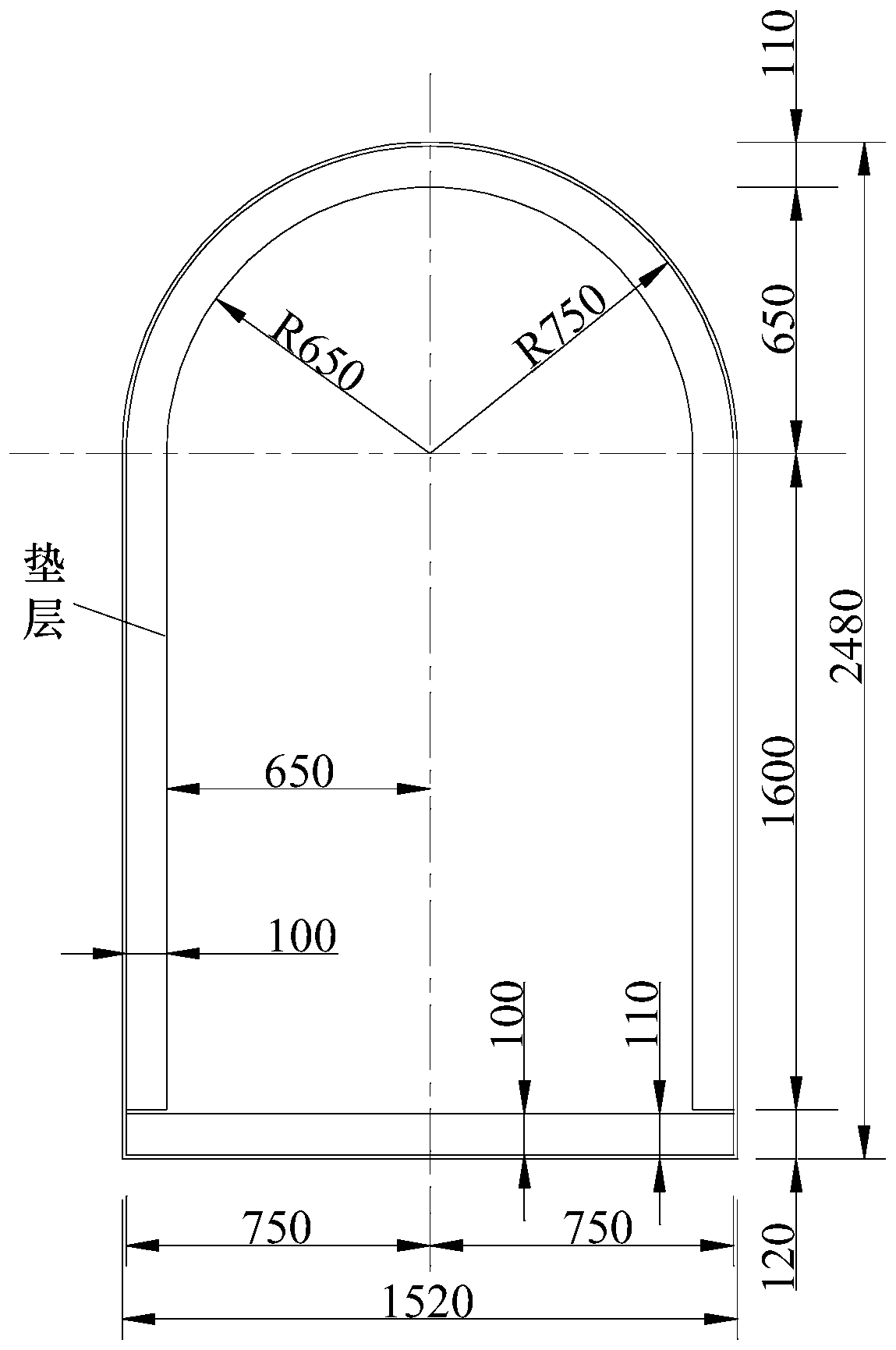

[0087] F2-type 1.0m-thick lining in the non-pressure section of the flood discharge tunnel in the type III1 surrounding rock area of the city gate tunnel

[0088] The 1.0m-thick F2 lining in the Class III1 surrounding rock area is the structural section with the largest number of Chengmen-type tunnels in the non-pressure section of the flood discharge tunnel, and it is difficult to control the temperature and crack resistance.

[0089] like Figure 5 As shown, the method for designing the temperature crack control crack resistance K value of the tunnel floor lining concrete provided in this embodiment includes the following steps:

[0090] Step 1. Collect the data used in the design and calculation of temperature crack control of the concrete lining of the city gate tunnel floor:

[0091] Lining structure design data, lining structure section, concrete strength grade; environmental data, deformation modulus of surrounding rock under geological conditions, annual variation ...

Embodiment 2

[0107] F4-type lining in the non-pressure section of the flood discharge tunnel in the type III2 surrounding rock area of the city gate tunnel

[0108] (1) The basic information is the same as above. In order to reduce the space, only a brief introduction to the summer temperature control calculation results in the design stage and construction real-time control stage.

[0109] (2) Analyze and determine the temperature control anti-cracking target and the allowable value of the anti-cracking safety factor [K]

[0110] The Xiluodu flood discharge tunnel is a first-class structure with high flow velocity and great damage caused by cracks during the operation period. Referring to similar engineering experience, according to Table 1, the temperature-controlled crack resistance target of the lining concrete is grade 1 crack resistance, and the allowable value of the anti-crack safety factor [K] is 1.6.

[0111] (3) Design of temperature control and anti-cracking scheme in desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com