Normal-pressure phase change heat storage device

A phase change heat storage, atmospheric pressure technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., to achieve good application prospects, stable phase change process, and stable heat output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

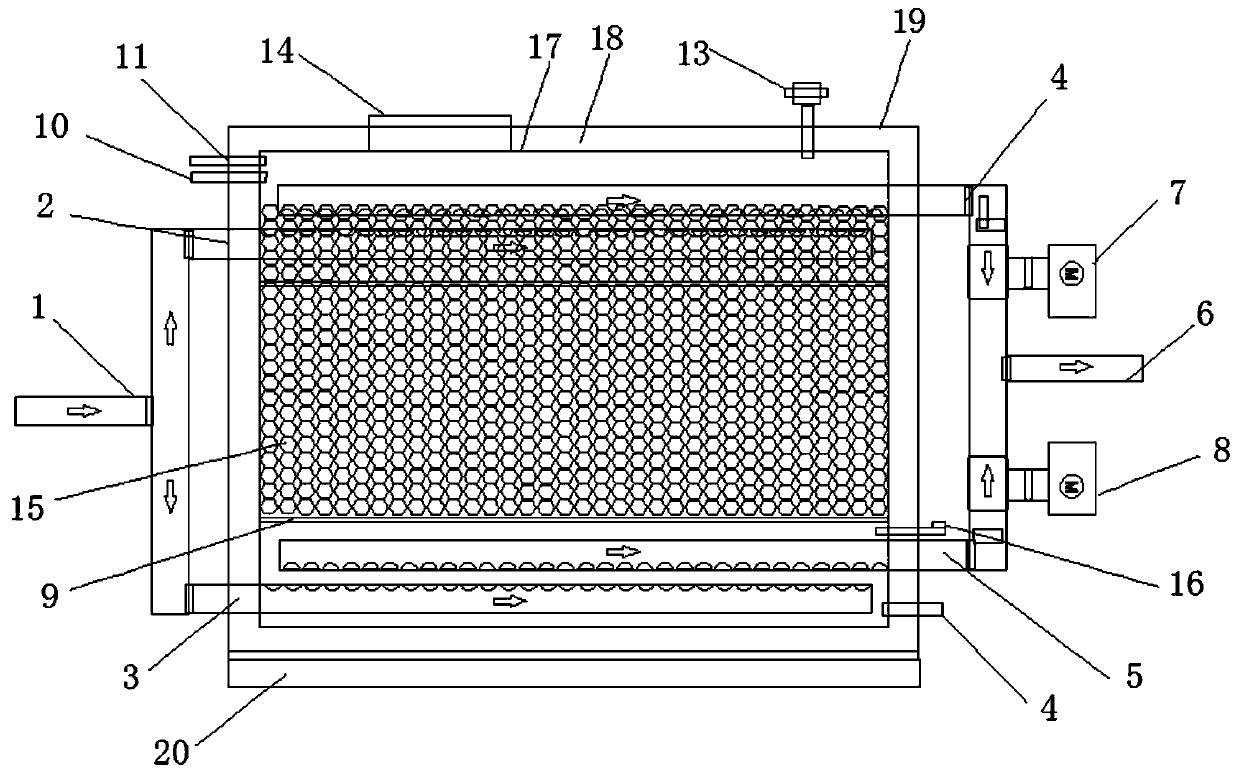

[0012] Such as figure 1 As shown, a kind of atmospheric pressure phase change heat storage device described in this embodiment, wherein: comprises main water inlet pipe 1, heat supply water inlet pipe 2, heat storage water inlet pipe 3, heat supply water outlet pipe 4, heat storage water outlet pipe 5, Main outlet pipe 6, heating electric two-way valve 7, heat storage electric two-way valve 8, partition 9, water supply port 10, overflow port 11, sewage outlet 12, exhaust hole 13, inspection port 14, energy storage ball 15. Liquid level sensor 16, liner 17, insulation layer 18, shell 19, base 20; the heat preservation layer 18 is set between the liner 17 and the shell 19, and the water outlet of the main water inlet pipe 1 is divided into upper and lower lines , the water outlet of one main water inlet pipe is connected to the water inlet of the heating water inlet pipe 2, the water outlet of the other main water inlet pipe is connected to the water inlet of the heat storage wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com