Axial force balance and sealing structure and high power density centrifugal fan

A technology with high power density and sealing structure, applied in the direction of engine sealing, mechanical equipment, radial flow pump, etc., can solve the problems of complex structure of axial force balance device and sealing device, achieve good dynamic characteristics and simplify the system Structure, high-speed rotation and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

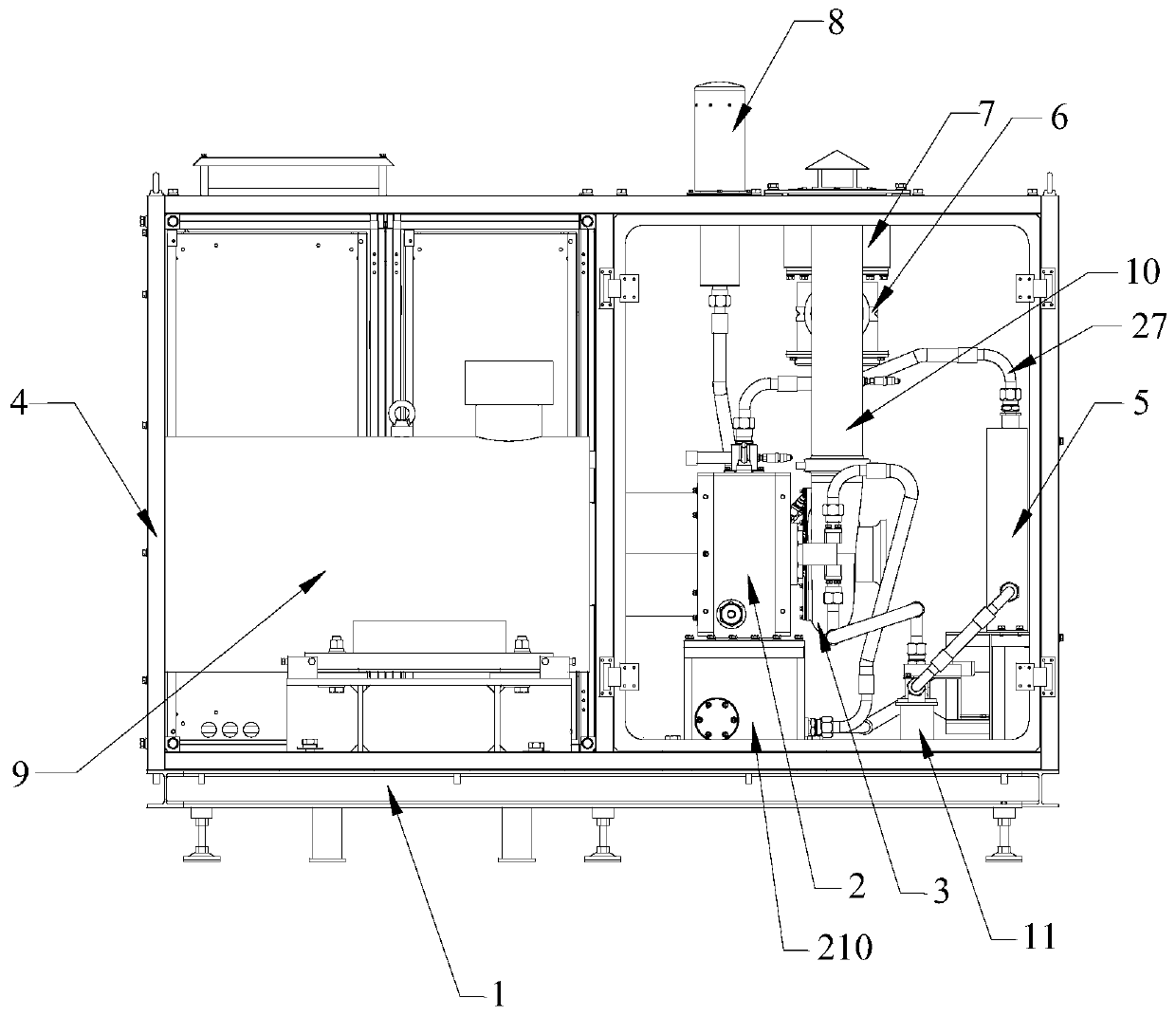

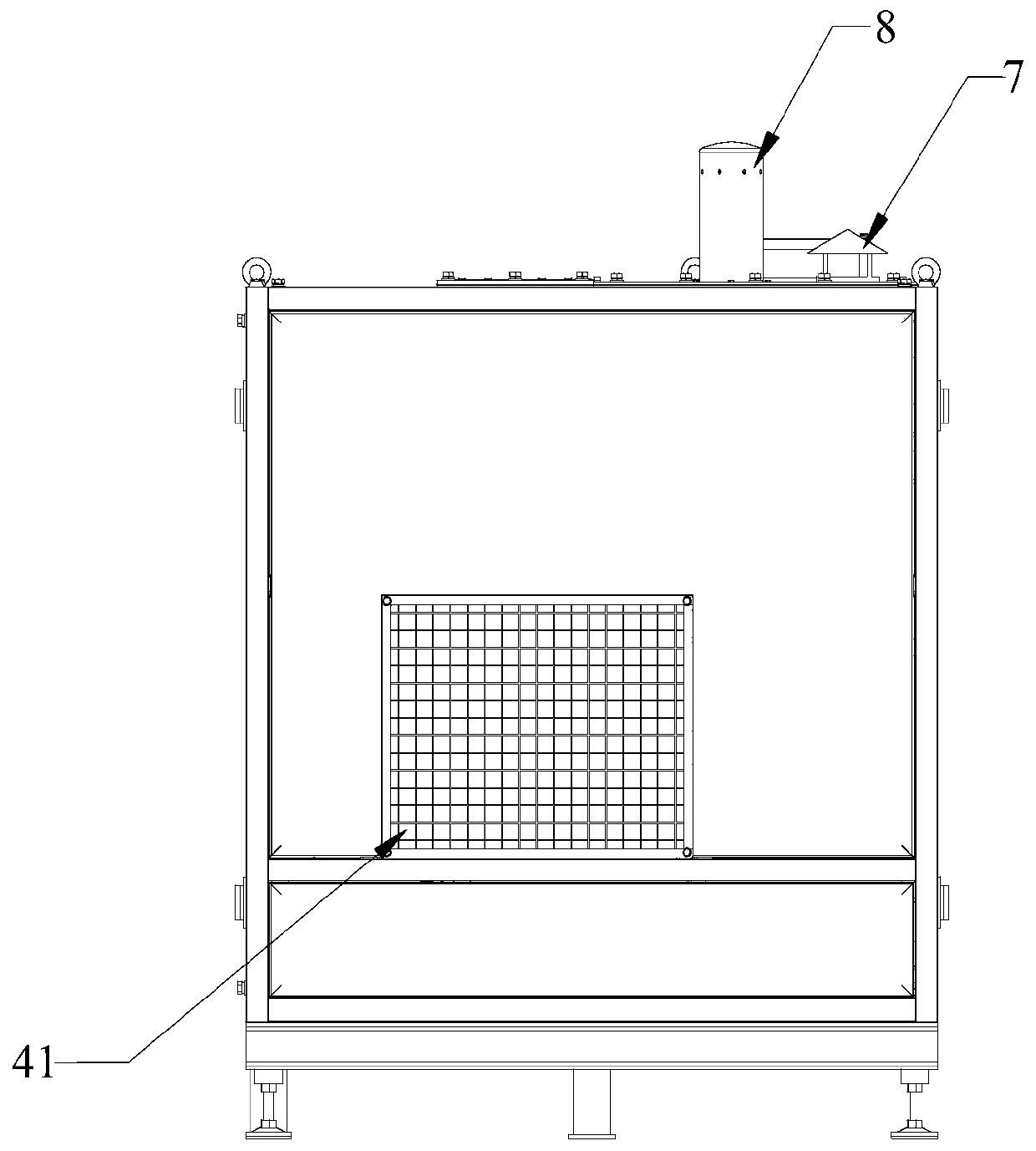

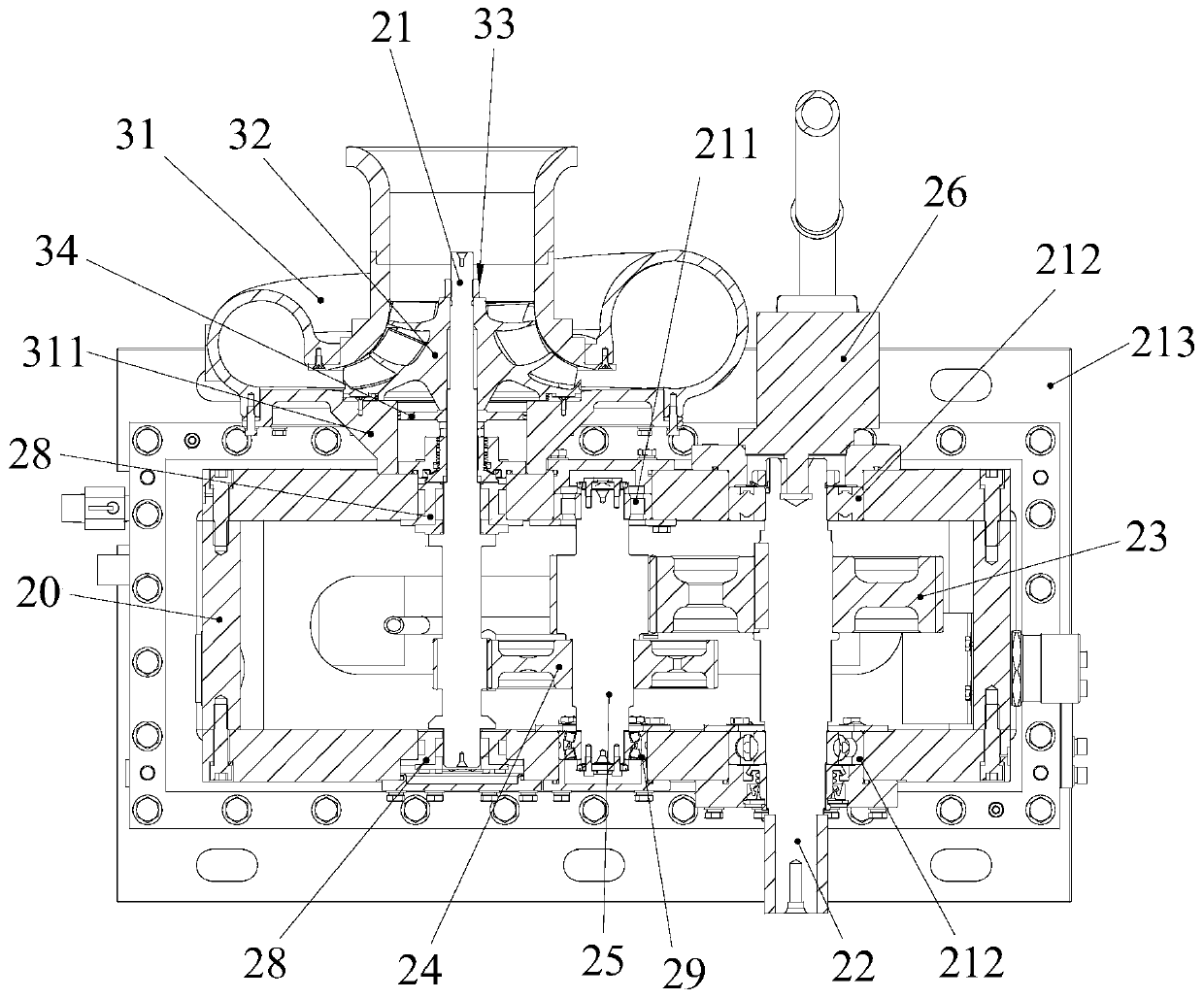

[0028] Such as figure 1 with figure 2 As shown, the preferred embodiment of the present invention provides a high power density centrifugal fan, which includes a base 1, a high-speed gearbox 2, a volute impeller assembly 3, a cabinet 4, an oil radiator 5, Vent valve 6, muffler assembly 7, oil-gas separation assembly 8, three-phase asynchronous motor 9, air outlet pipe 10 and oil filter 11, the cabinet body 4 is installed on the base 1, and the base 1 plays a supporting role, The cabinet 4 plays a role of safety protection, and the high-speed gear box 2, the volute impeller assembly 3, the oil radiator 5, the vent valve 6, the three-phase asynchronous motor 9, the air outlet pipeline 10 and the oil filter 11 are all Installed inside the cabinet body 4 , the nois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com