Rigid sleeve valve pipe assembly and using method thereof

A sleeve valve tube and component technology, which is applied in the field of construction components for strengthening tunnel surrounding rock, can solve problems such as rubber valve falling off, achieve the effects of avoiding falling off, facilitating transportation and construction, and saving grouting slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

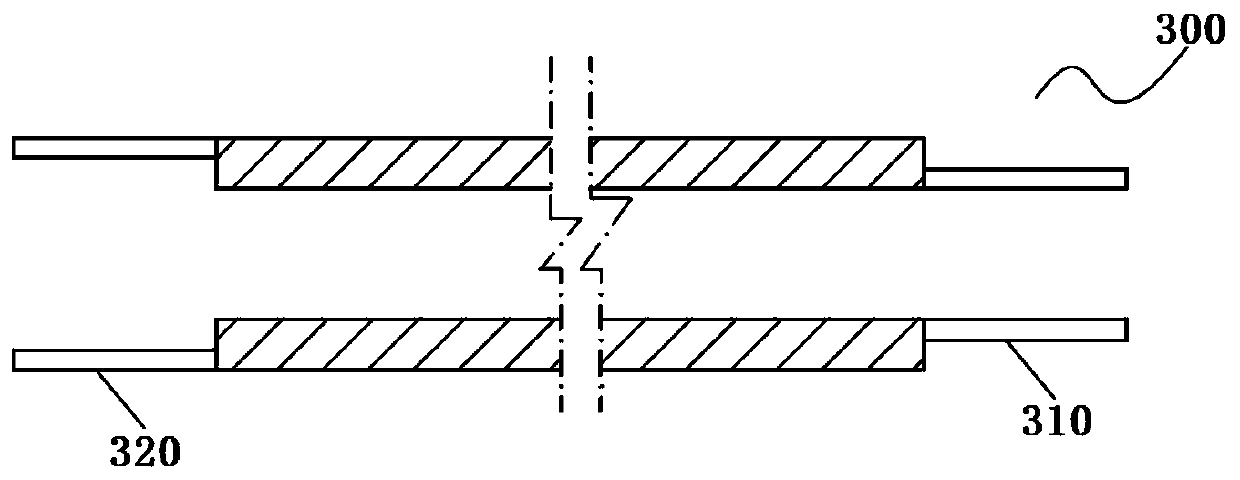

[0032] Next, the rigid sleeve valve tube assembly of the present invention and its usage method will be described in detail with reference to the accompanying drawings.

[0033] First, please refer to Figure 1A ~ Figure 1C , the rigid cuff tube assembly of the present invention includes a first-type cuff tube body 100 , a second-type cuff tube body 200 , and a third-type cuff tube body 300 . The first type sleeve valve body 100, the second type sleeve valve body 200, and the third type sleeve valve body 300 have the same pipe diameter size, and they are made of hot-rolled seamless steel tubes with a diameter of 42 mm and a wall thickness of 8 mm. Made of steel pipe.

[0034] Such as Figure 1A As shown, the length of the first type sleeve valve body 100 is 5 meters, the front end of the first type sleeve valve body 100 is closed, the length of the tip 110 is set to 10 cm, and the first type sleeve valve body 100 is far away from the tip One end of 110 is provided with inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com