Loose fiber continuous washing and finishing machine

A technology of loose fiber and finishing machine, which is applied in liquid/gas/vapor fiber/sliver/roving processing, textile material drum processing, textile material carrier processing, etc. Energy consumption and other issues, to achieve the effect of improving production connection efficiency, improving cleaning effect, and increasing concentration gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

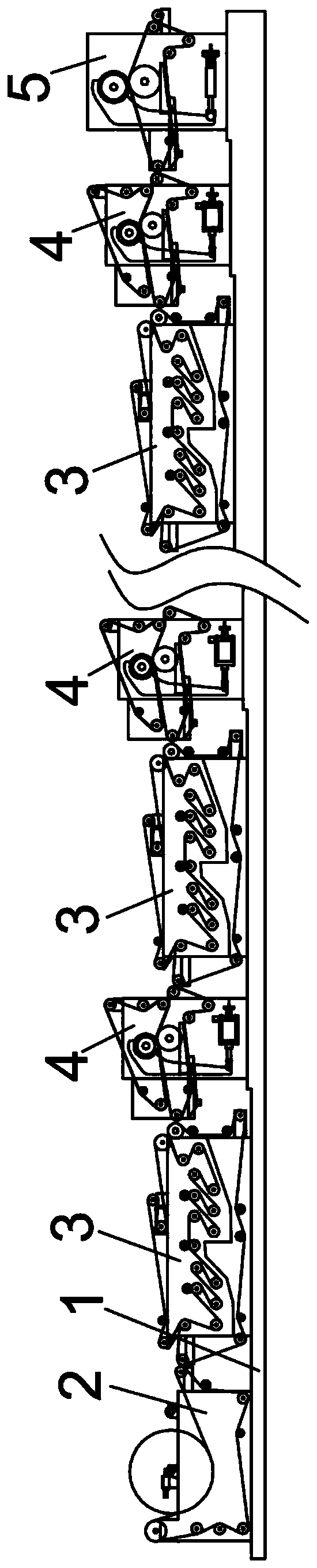

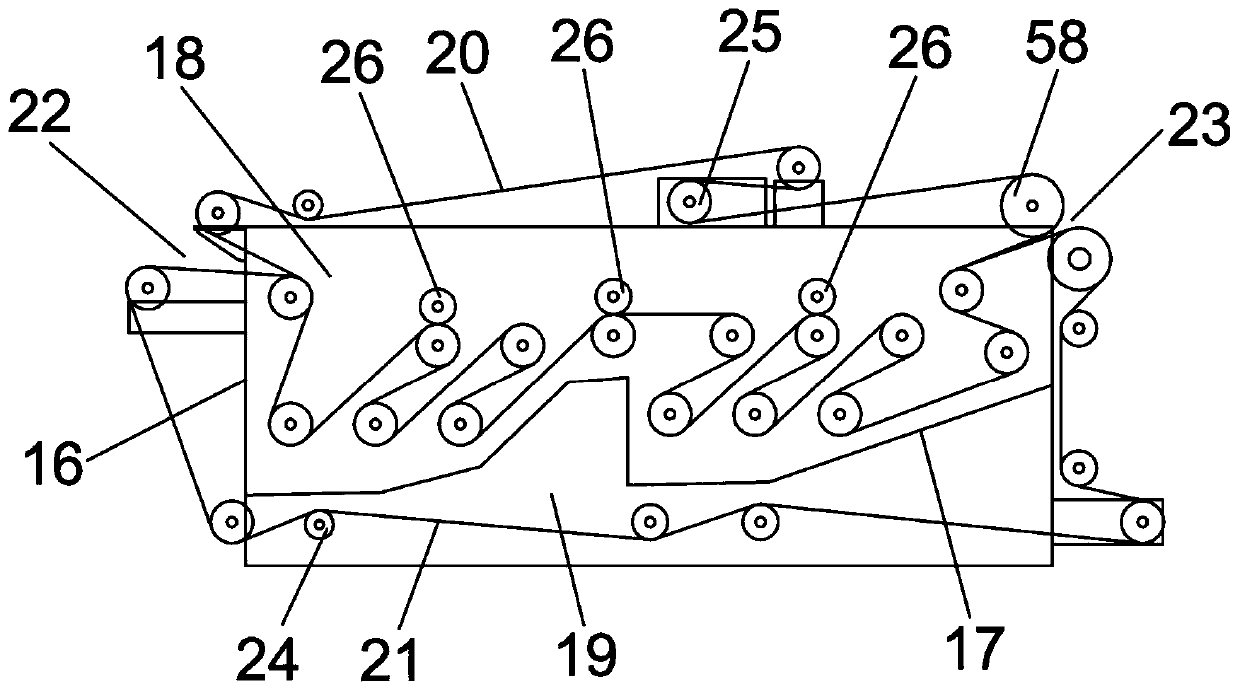

[0032] Embodiment: a kind of bulk fiber continuous washing finishing machine, as Figure 1-Figure 8 As shown, it includes a base (1), on which an unwinding device (2), a water washing device (3), a rolling device (4) and an extrusion The water device (5), the water washing device (3) and the rolling device (4) are provided in multiples, and the water washing device (3) and the rolling device (4) are arranged at intervals.

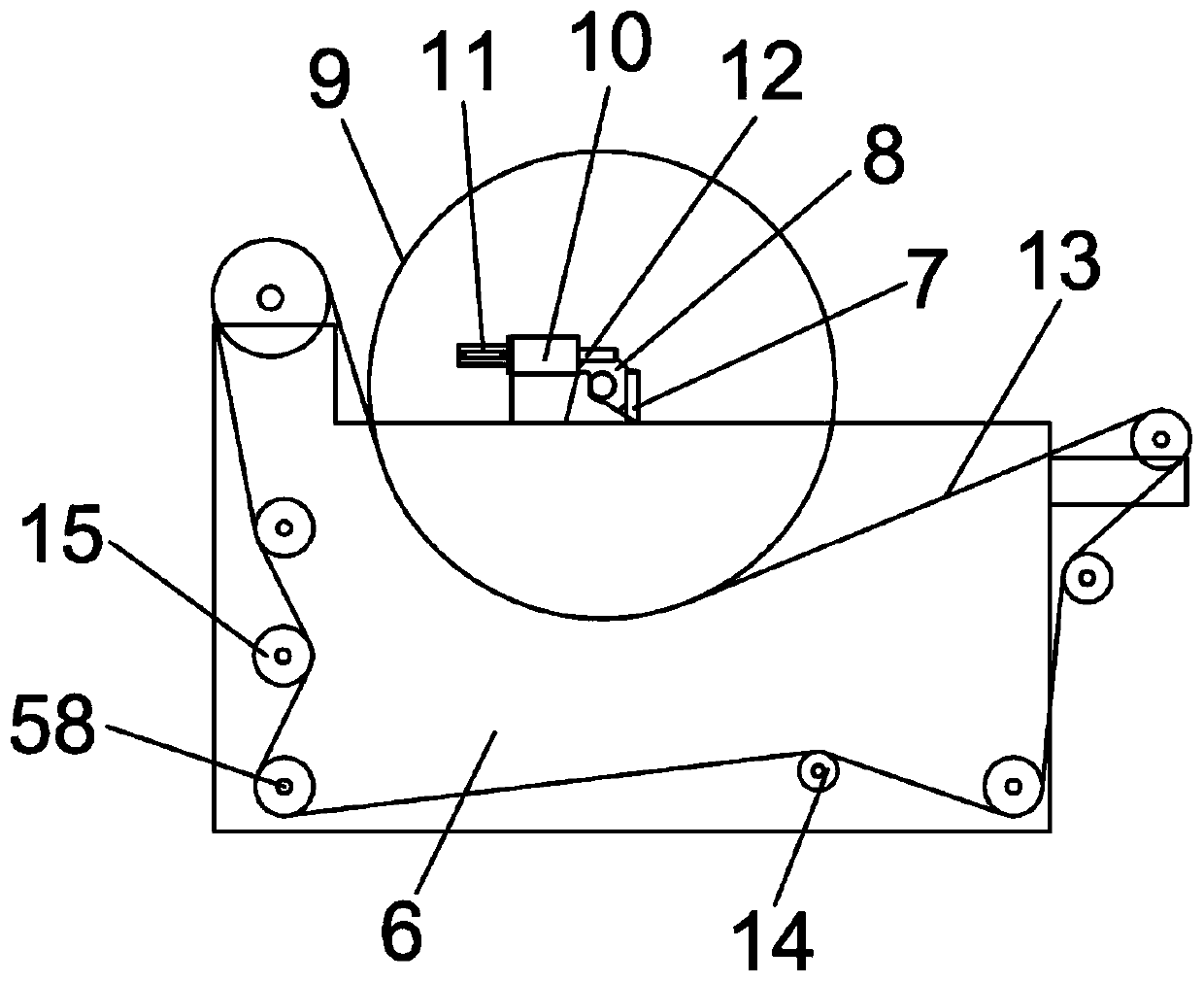

[0033] The unwinding device (2) comprises an unwinding frame (6) and a first conveying module matched with the unwinding frame (6), and the front and rear sides of the top of the unwinding frame (6) are provided with a mobile trolley ( 7), the mobile trolley (7) is connected to the drive cylinder, and is slidably connected to the top of the unwinding frame (6), and a roller (8) is arranged between the two mobile trolleys (7), and the roller ( 8) is loaded with a fiber roll (9), and the fiber roll (9) is wound from a fiber layer, and the front and rear side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com