A pressure-limiting manual press

A press and pressure limiting technology, which is applied in the field of presses, can solve the problems of affecting the comfort, damaging the workpiece structure, and increasing the product scrap rate, so as to reduce the probability of processing errors, prevent excessive pressure, and prevent workpiece damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

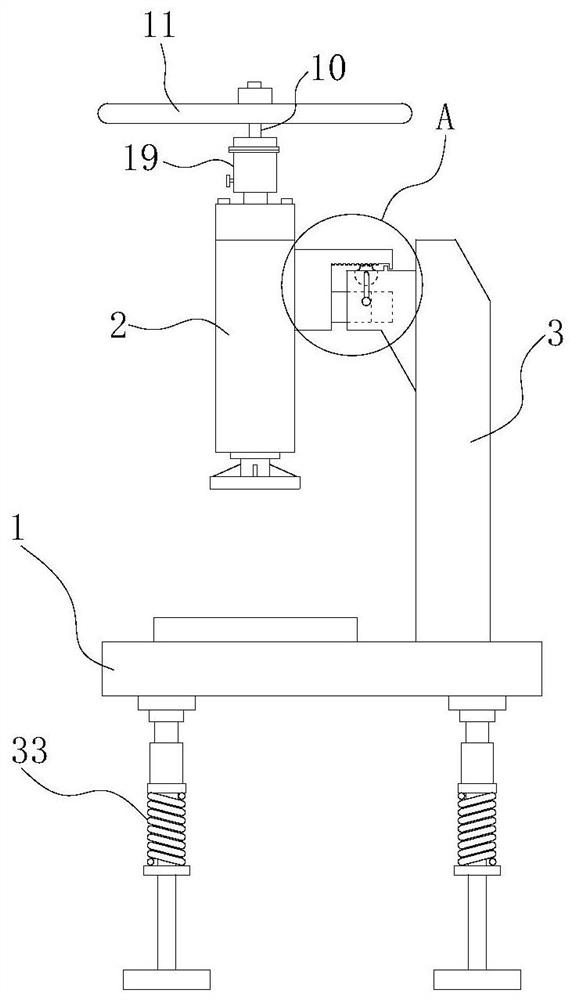

[0025] to combine Figure 1-9 The manual press shown is the same as the traditional manual press, and it mainly includes a base 1 and a pressing device 2. The pressing device 2 is erected above the base 1 through an inverted L-shaped support arm 3, and the pressing device 2 is provided with a pressing device. The head 7 is manually driven by the user to move downward toward the base 1 to realize extrusion processing of the workpiece on the base 1 . There are many specific types of the pressing device 2 , for example: screw driven, rack and pinion driven, lever driven and so on.

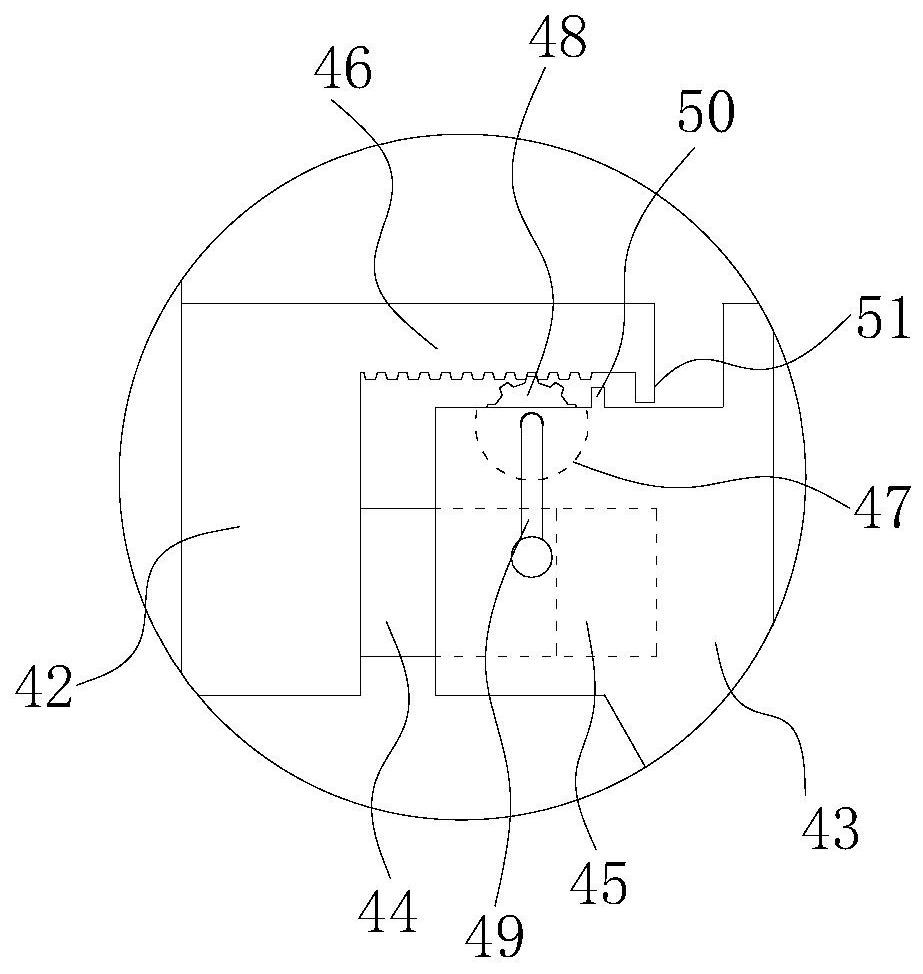

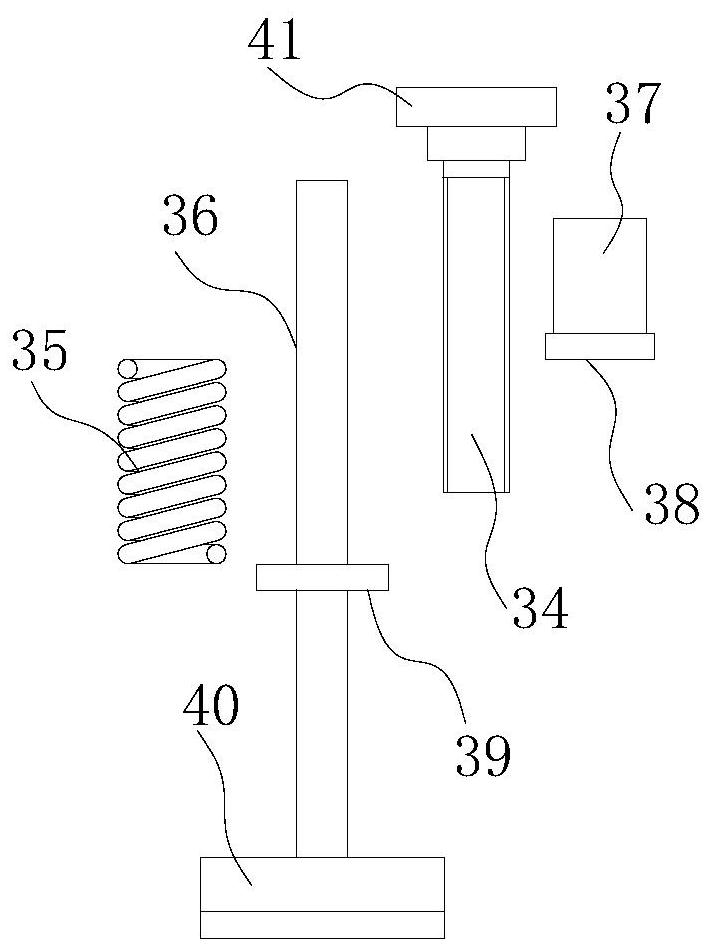

[0026] The improvement of the first aspect of the present invention is considered from the aspect of pressure limitation, and the screw-driven pressing device 2 is specifically improved. The screw-driven pressing device 2 is substantially the same as the pressing device 2 in the prior art, as Figure 4 As shown, the pressing device 2 includes a vertical mounting cylinder 4 and a screw 5 fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com