Method for desorbing heavy metal ions on surface of plastic

A technology of heavy metal ions and metal ions, applied in the field of environmental pollution control, can solve problems such as affecting environmental organisms, hindering the regeneration and utilization of microplastics, and affecting human health, and achieves the effects of low acid corrosion, simple operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

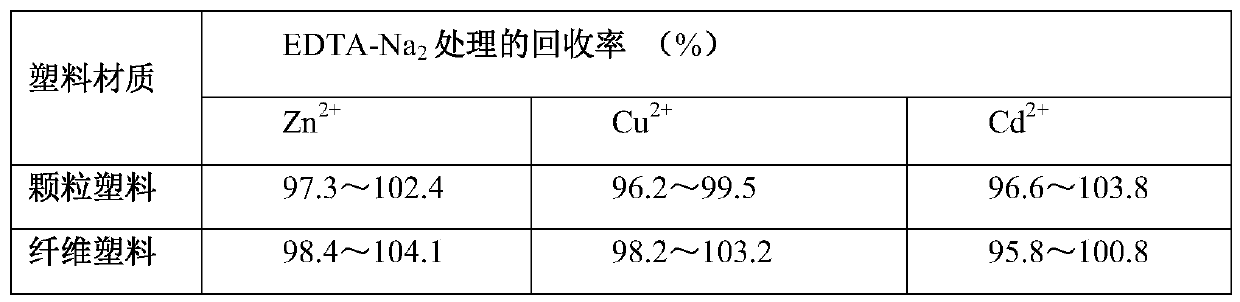

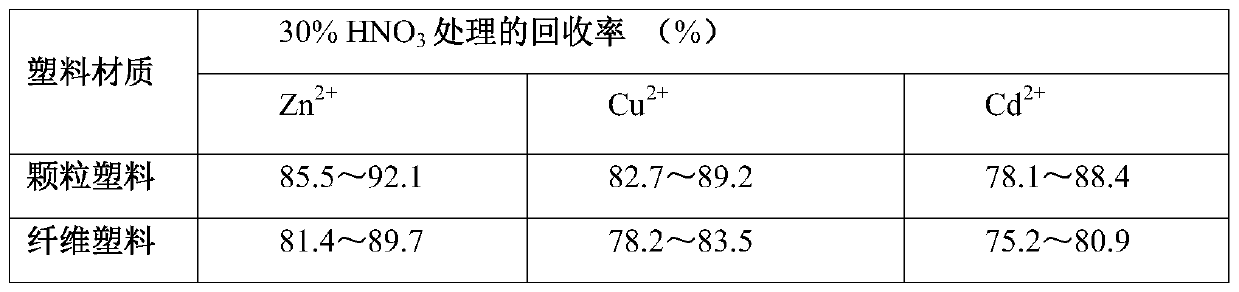

[0022] Embodiment 1 desorption experiment:

[0023] (1) The aging plastic comes from the plastic playground of the school that is often exposed to wind and sun. For a more accurate test of the desorption effect of the present invention, the collected plastics were desorbed with 5wt% HNO 3 After ultrasonic cleaning for 30 minutes, vacuum filter and wash with ultrapure water several times to remove various metal elements that may be adsorbed. Vacuum dried and cleaned plastics are visually classified into: granular plastics and fibrous plastics.

[0024] (2) Accurately weigh zinc sulfate, copper sulfate and chromium sulfate, respectively configure the standard solutions of zinc ions, copper ions and cadmium ions (C 0 , mg / L). Accurately weigh the mass as M 0 The granular plastics and cellulose plastics treated in step (1) are added to the above-mentioned zinc ions, copper ions and cadmium ions respectively, and shake overnight at 160r / min and 30°C in the dark to make the zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com