Desorption method of PSA oxygen making machine adsorption tower

An adsorption tower and desorption technology, applied in the field of oxygen production of a PSA oxygen generator, can solve problems such as affecting the oxygen yield, and achieve the effects of improving oxygen concentration, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

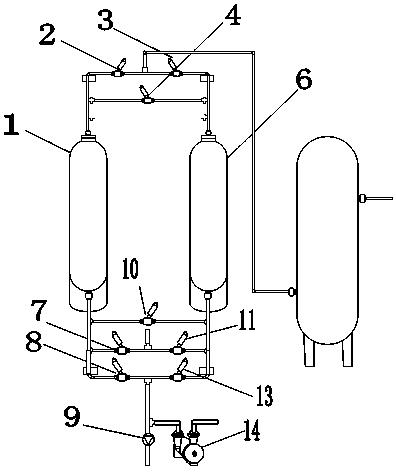

[0011] A desorption method for an adsorption tower of a PSA oxygen generator. Two exhaust pipes with a pipe diameter not smaller than the exhaust pipe are arranged on the exhaust pipe of the adsorption tower through a three-way valve, and one of the exhaust branch pipes is provided with an exhaust pipe. One-way valve 9, the initial stage of the desorption process is exhausted by the method of natural exhaust through the exhaust branch pipe equipped with exhaust one-way valve 9; another exhaust branch pipe is connected with negative pressure device 14, when the adsorption tower is in During the desorption process, exhaust gas naturally until the pressure drops to 0.04-0.06 MPa, preferably 0.05 MPa, and the negative pressure device 14 (open) works to quickly discharge the remaining gas in the adsorption tower. The opening working pressure of the negative pressure device 14 is determined according to the working time and pressure debugging of the specific PSA oxygen generator. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com