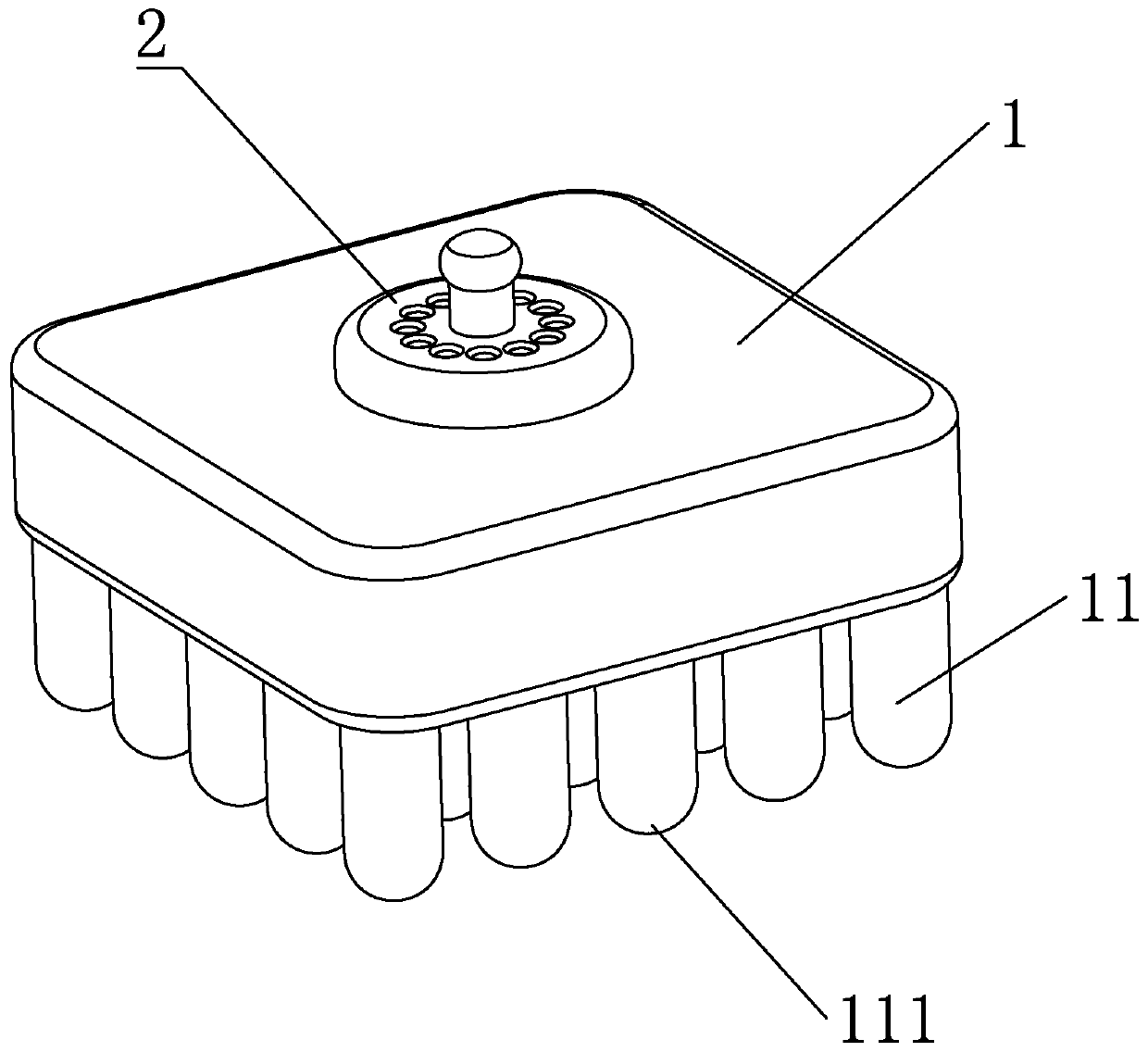

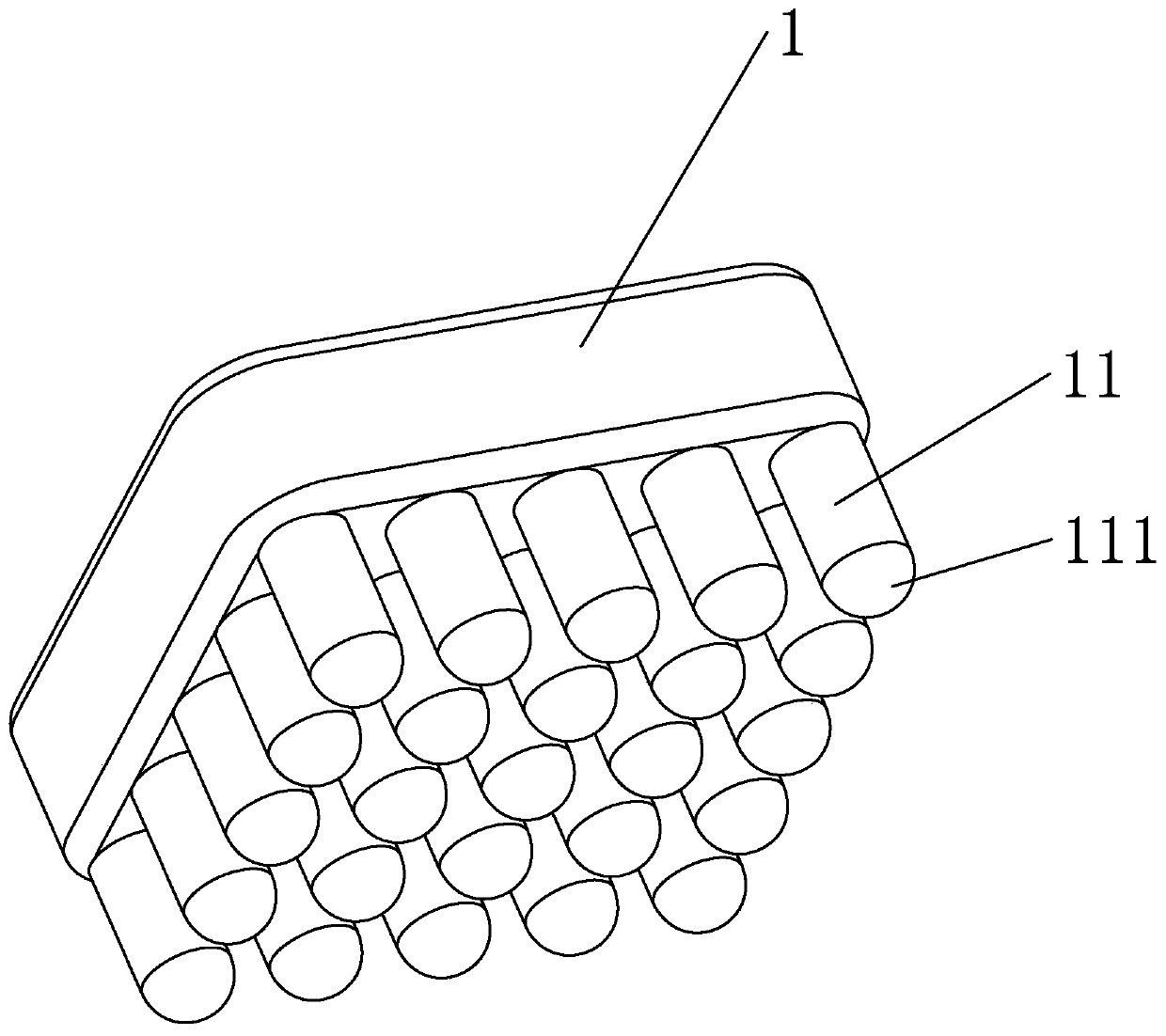

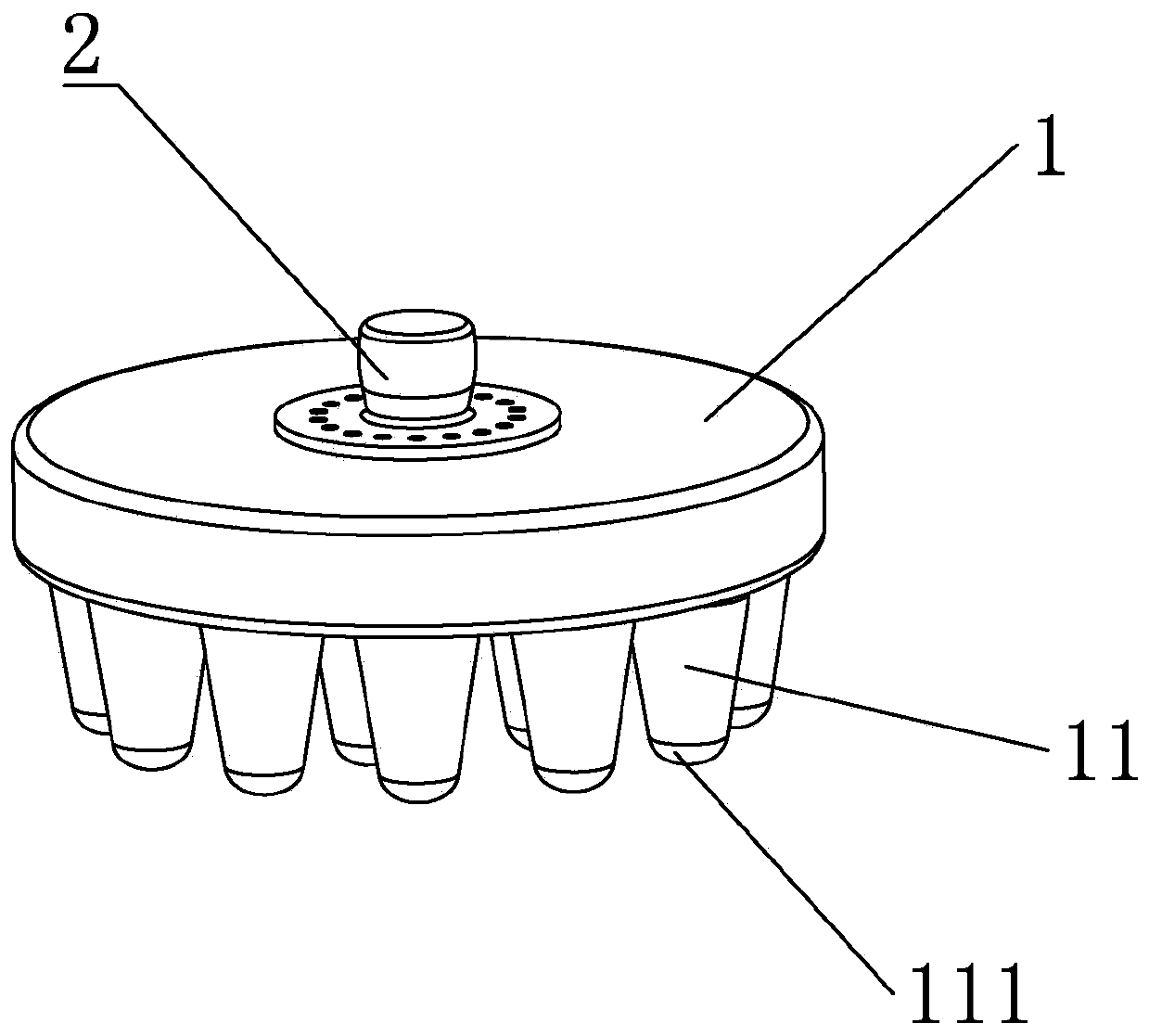

Contact impedance small flexible dry electrode and preparation method thereof

A contact impedance and flexible electrode technology, applied in the field of medical devices, can solve the problems of poor signal stability, easy air-drying of conductive gel, high production cost, etc., achieve excellent conductivity and flexibility, realize daily activity monitoring, and good geometric adaptation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Mixing: Mix silicone rubber particles and nano-silver powder at a ratio of 100%: 30%, and stir evenly, move to the electrode mold and pressurize and heat for 1 minute to form it. The forming pressure is 45kg / cm 2 , the forming temperature is 165°C;

[0048] (2) Vulcanization: In the electrode mold, keep the molding pressure at 45kg / cm 2 , Vulcanize for 30 minutes at a molding temperature of 120°C to obtain a semi-finished product;

[0049] (3) Heating: Bake the semi-finished product obtained by vulcanization at 210°C for 1.5 hours, and then cool to room temperature;

[0050] (4) Cleaning: the semi-finished product after heating and baking is cleaned with 0.2mol / L sodium chloride solution, and the flexible electrode body is obtained after drying;

[0051] (5) Assembling: fix the electrical connectors on the flexible electrode body, it is obtained.

Embodiment 2

[0053] (1) Mixing: Mix silicone rubber particles and double-layer graphene at a ratio of 100%: 25%, and stir evenly, move to the electrode mold and pressurize and heat for 2 minutes to form it. The forming pressure is 50kg / cm 2 , the molding temperature is 150°C;

[0054] (2) Vulcanization: In the electrode mold, keep the molding pressure at 50kg / cm 2 , vulcanize for 40 minutes at a molding temperature of 110°C to obtain a semi-finished product;

[0055] (3) Heating: Bake the semi-finished product obtained by vulcanization at 200°C for 2 hours, and then cool to room temperature;

[0056] (4) Cleaning: wash the semi-finished product after heating and baking with 1.0mol / L sodium chloride solution, and dry it to obtain a flexible electrode body;

[0057] (5) Assembling: fix the electrical connectors on the flexible electrode body, it is obtained.

Embodiment 3

[0059] (1) Mixing: Mix silicone rubber particles and nano-silver powder at a ratio of 100%: 20%, and stir evenly, move to the electrode mold and pressurize and heat for 1.5 minutes to form it. The forming pressure is 60kg / cm 2 , the molding temperature is 170°C;

[0060] (2) Vulcanization: In the electrode mold, keep the molding pressure at 60kg / cm 2 , vulcanize for 30 minutes at a molding temperature of 110°C to obtain a semi-finished product;

[0061] (3) Heating: Bake the semi-finished product obtained by vulcanization at 220°C for 1 hour, and then cool to room temperature;

[0062] (4) Cleaning: wash the semi-finished product after heating and baking with 0.2mol / L sodium oxalate solution, and dry it to obtain the flexible electrode body;

[0063] (5) Assembling: fix the electrical connectors on the flexible electrode body, it is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com