Hardware electromechanical switch for improving safety

An electromechanical switch and safety technology, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problem of damage to the pin joint stiffness of the configuration board and the support board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with examples.

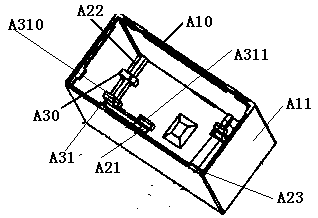

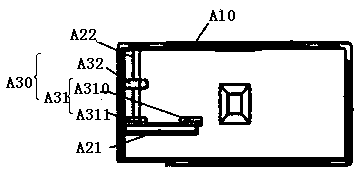

[0023] Such as Figure 1-Figure 2 As shown, the metal electromechanical switch with improved safety in this embodiment includes a cover body A10 and a configuration plate; here, the configuration plate includes a pin joint plate A21 and a reference glass bronze plate A22; the pin joint plate A21 penetrates the cover body A10 Behind the side panels A11 of the side panels, they are respectively located in the hollow chamber of the cover body 110;

[0024] The stabilizing device A30 equipped on the side panel A11 of the cover body A10 of the hardware electromechanical switch can be a barrier plate structure; the stabilizing device A30 can include a barrier plate A31; The position of the connecting range of the glass bronze plate A22, and the head wall of the side surface A12 of the side surface A12 facing the cover body A10 with the pin joint plate A21;

[0025] The stabilizing device A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com