Nitrogen spring structure

A nitrogen gas spring and cylinder technology, used in springs, springs/shock absorbers, gas shock absorbers, etc., can solve problems such as cylinder bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

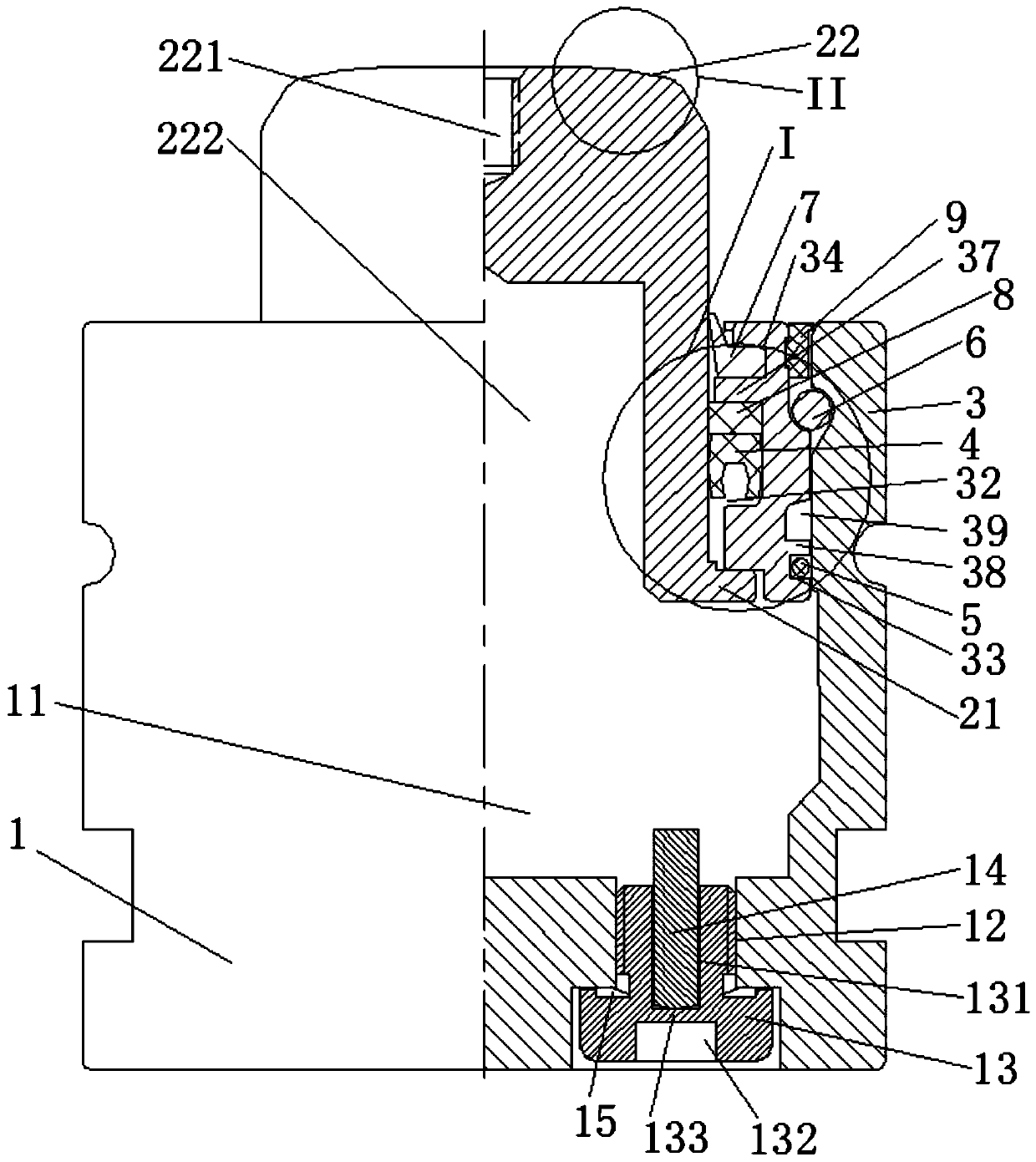

[0030] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

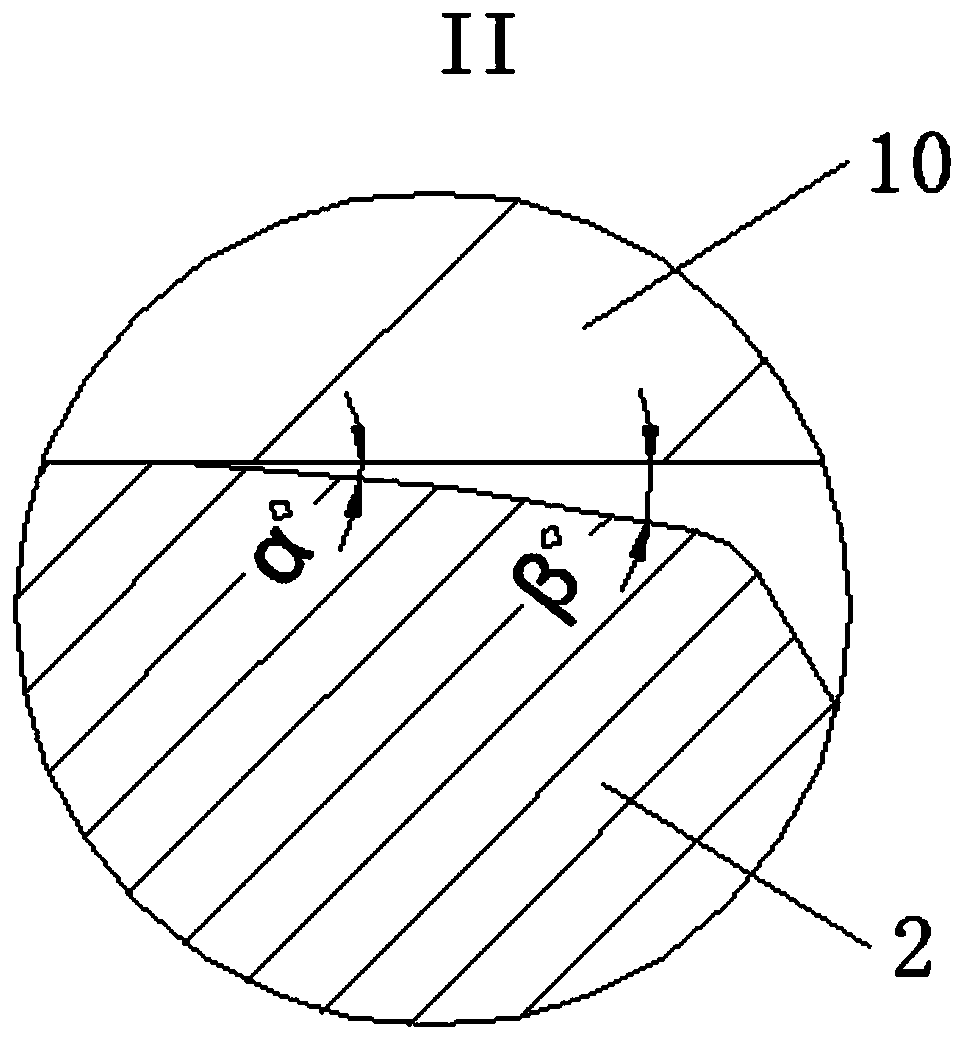

[0031] see figure 1 , 2 As shown, a nitrogen gas spring structure includes a cylinder body 1, a plunger rod 2 and an intermediate sleeve 3, the cylinder body 1 is provided with a cylinder hole 11, and the intermediate sleeve 3 is sealed and connected to the upper part of the inner wall of the cylinder hole 11, and the column The plug rod 2 is slidingly connected with the inner hole of the middle sleeve 3 in a sealing manner, and the cylinder hole 11 of the cylinder body 1 is filled with high-pressure nitrogen gas. The boss 21 , and the outer first step 211 has a thickness smaller than the second step 212 , and is also smaller than the thickness of the stopper boss 31 . Ensure that the thinnest first step 211 breaks first, and the second step 212 can resist the limiting boss 37 during the flying out process. And the inner wall of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com