Steam ejector

A technology of ejector and steam, which is applied in jet pumps, machines/engines, non-volume pumps, etc., and can solve the problem of low energy efficiency of steam ejectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the drawings and embodiments.

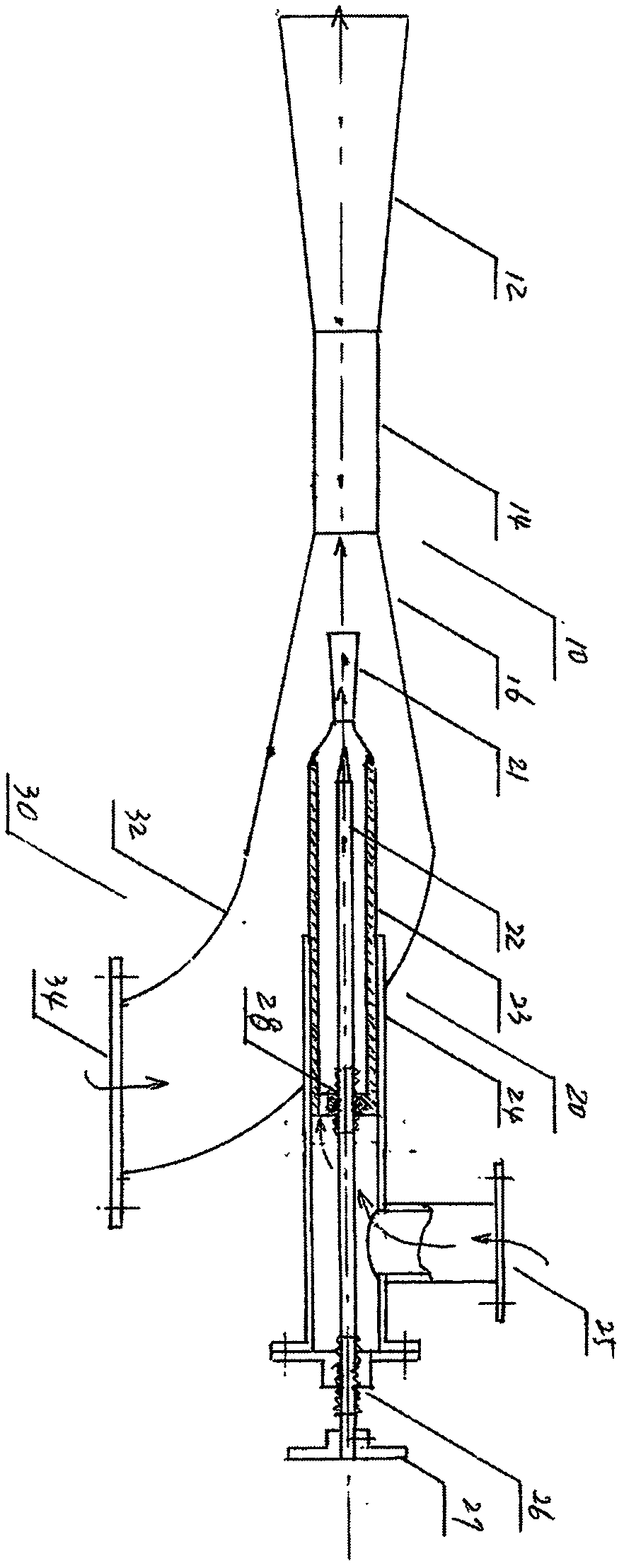

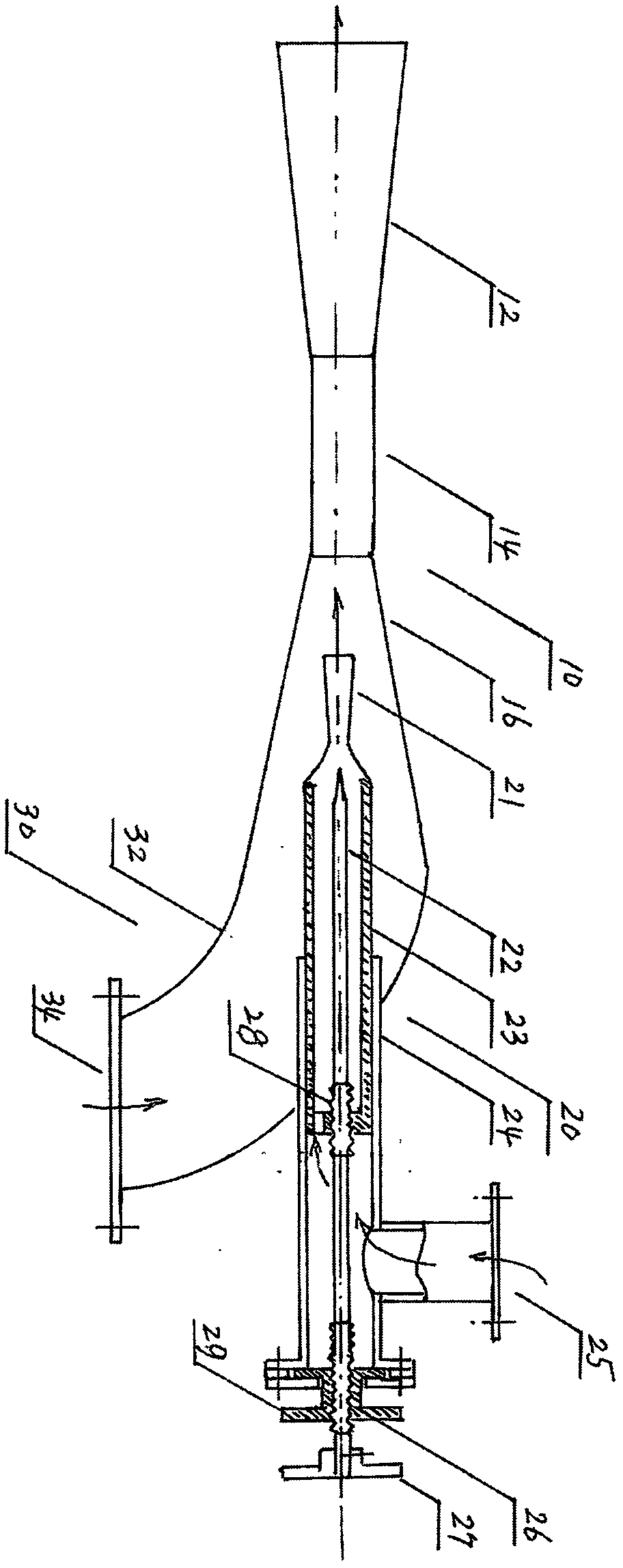

[0028] figure 1 The overall picture of the existing steam ejector is given.

[0029] The existing steam ejector is mainly composed of three parts: a diffuser tube 10, a nozzle 20, and a suction chamber 30.

[0030] The structure of the diffuser tube 10 includes: a divergent outlet section 12, a throat 14 with a constant cross section, and a tapered inlet section 16.

[0031] The structure of the nozzle 20 includes: a nozzle outlet 21, a nozzle steam inlet pipe 23, a nozzle core shaft 22, a sleeve 24, a driving steam inlet 25, an end thread 26, a hand wheel 27, and a steam inlet pipe thread 28.

[0032] The smallest cross section between the nozzle outlet 21 and the nozzle steam inlet pipe 23 is the nozzle throat, and the front end of the nozzle throat is connected to the nozzle inlet. The nozzle mandrel 22 is adjusted by the hand wheel 27 and relies on the end thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com