Ceramic membrane, modifying method thereof, filter and filter system

A filtration system and ceramic membrane technology, used in hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of filter blockage, poor catalyst and moisture effect, and reduced gas flux, etc., to improve service life, large flux, and low The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

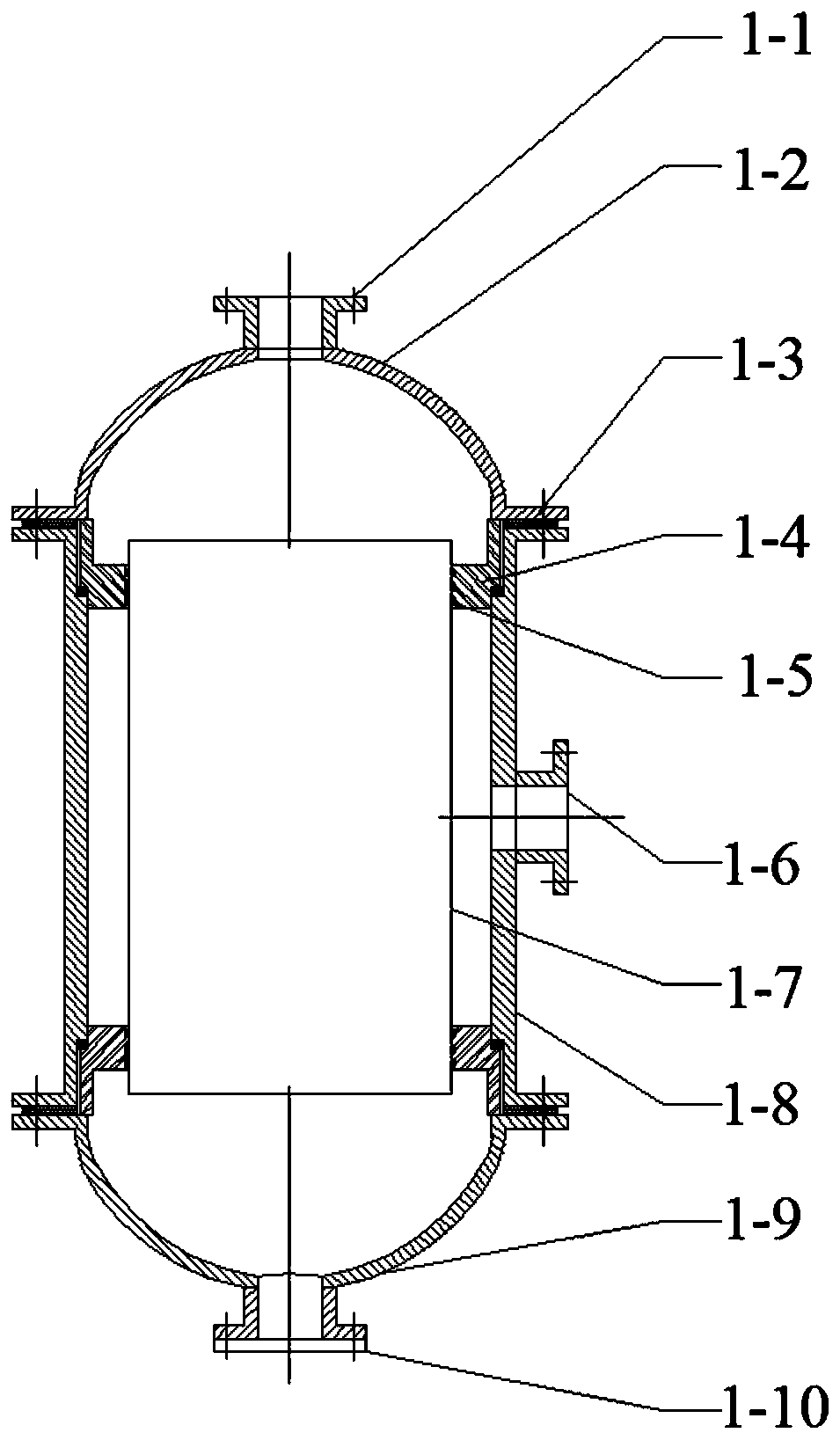

[0047] This embodiment provides a filter, see figure 2 , including ceramic membrane cylinder 1-7, upper membrane cover 1-2, lower membrane cover 1-9 and membrane shell 1-8, the upper membrane cover and the lower membrane cover are arranged at opposite ends of the membrane shell, and also include,

[0048] The gasket 1-3 is arranged between the upper membrane cover 1-2 and one end of the membrane shell 1-8, and between the lower membrane cover 1-9 and the opposite end of the membrane shell 1-8;

[0049] The snap rings 1-4 are respectively clipped on the inner walls of the opposite ends of the membrane shell 1-8, and the two ends of the ceramic membrane tube 1-7 are suitable to be sleeved on the snap ring 1-4 and are its fixed;

[0050] The O-shaped sealing ring 1-5 is arranged between the snap ring 1-4 and the ceramic membrane tube 1-7, so that the snap ring 1-4, the inner wall of the membrane shell 1-8, the ceramic membrane tube 1- A sealed space for containing hydrogen is ...

Embodiment 2

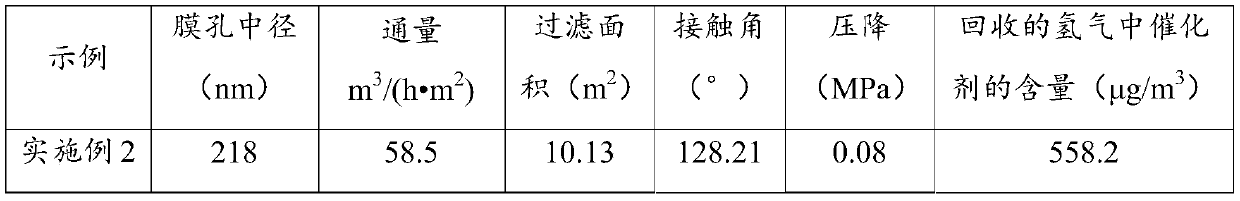

[0062] This embodiment provides a method for modifying a ceramic membrane, including:

[0063] The alumina ceramic membrane was soaked in 5wt% polytetrafluoroethylene aqueous solution, heated to 350°C at 1.2°C / min, and kept at this temperature for 3 hours to obtain a modified ceramic membrane;

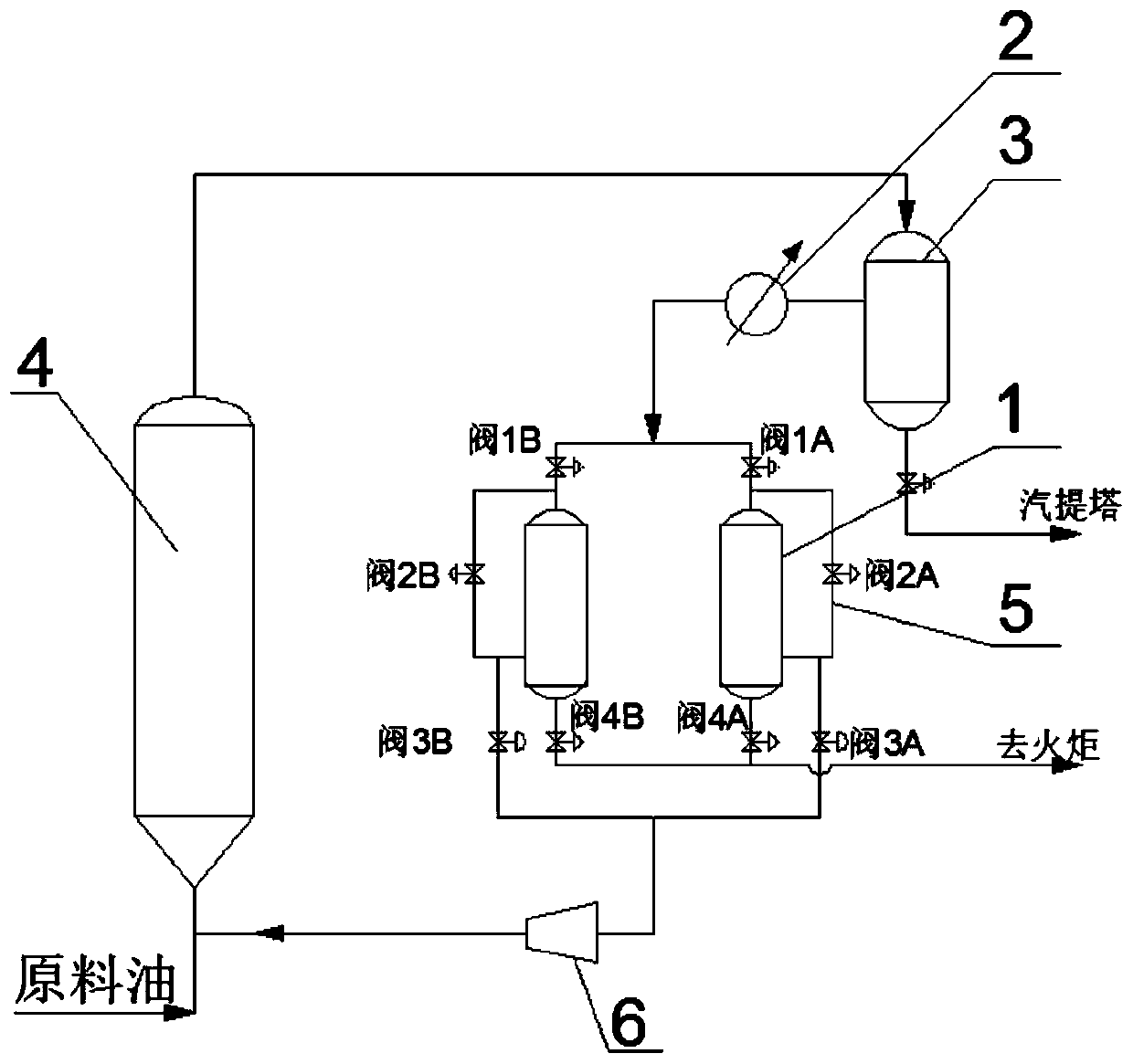

[0064] This embodiment also provides a hydrogen recovery method comprising the above-mentioned modified ceramic membrane and adopting the suspension bed hydrogenation reaction of the filtration system described in Embodiment 1, comprising:

[0065] The suspended bed reactor discharges the reaction product containing hydrogen, oil and other mixtures. After passing through the hot high-pressure separator, the hydrogen-containing gas mixture enters the heat exchanger, and the oil enters the stripping tower. The hydrogen-containing gas mixture undergoes heat exchange. The modified ceramic membrane separates hydrogen and other gas impurities, and the separated hydrogen enters the suspended ...

Embodiment 3

[0069] This embodiment provides a method for modifying a ceramic membrane, including:

[0070] The alumina ceramic membrane was soaked in 15wt% polytetrafluoroethylene aqueous solution, heated at 0.8°C / min to 370°C, and kept at this temperature for 0.5h to obtain a modified ceramic membrane;

[0071] This embodiment also provides a hydrogen recovery method comprising the above-mentioned modified ceramic membrane and adopting the suspension bed hydrogenation reaction of the filtration system described in Embodiment 1, comprising:

[0072] The suspended bed reactor discharges the reaction product containing hydrogen, oil and other mixtures. After passing through the hot high-pressure separator, the hydrogen-containing gas mixture enters the heat exchanger, and the oil enters the stripping tower. The hydrogen-containing gas mixture undergoes heat exchange. The modified ceramic membrane separates hydrogen and other gas impurities, and the separated hydrogen enters the suspended be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com