Cardanol-based photosensitive resin for 3D printing and preparation method thereof

A cardanol-based, 3D printing technology, applied in the direction of additive processing, etc., to achieve the effect of increased and controllable crosslinking rate, improved impact strength, and reduced application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

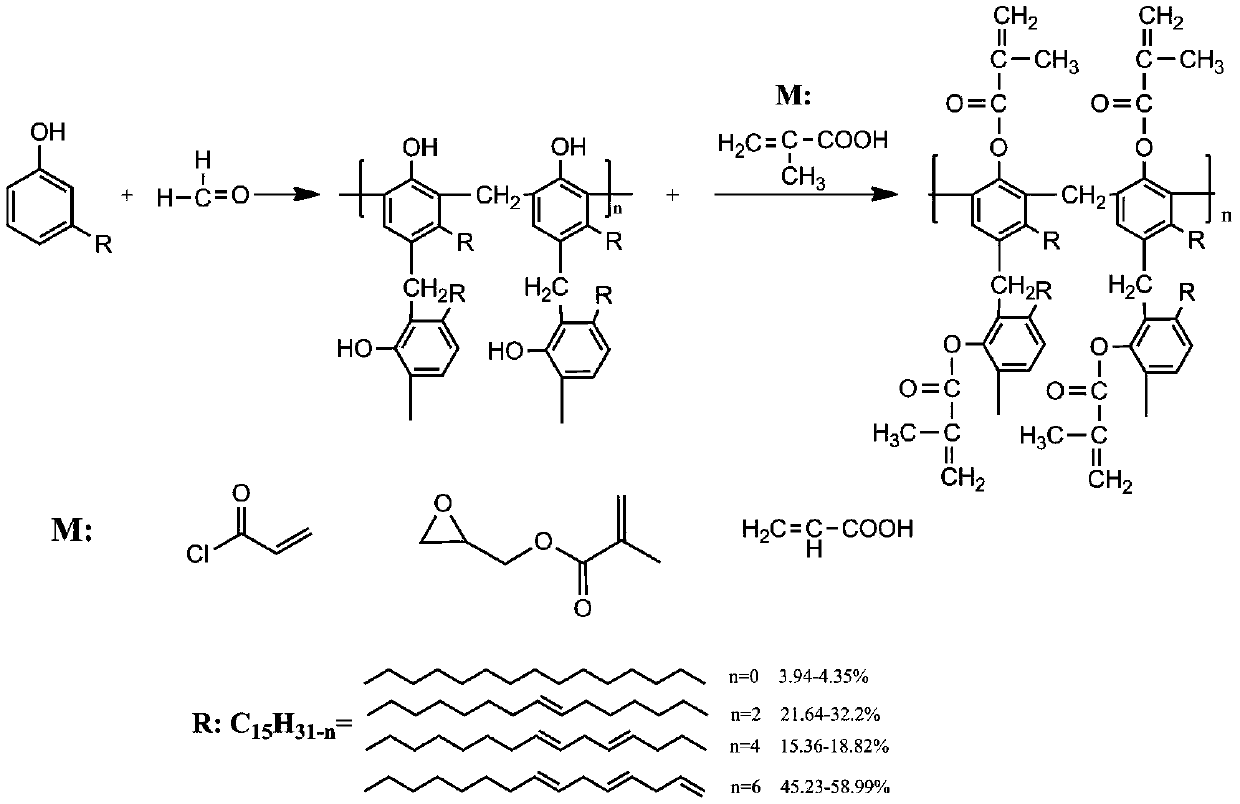

[0025] A kind of preparation method of cardanol-based photosensitive resin for 3D printing, it comprises the steps:

[0026] 1) Using xylene as solvent, add 100g of cashew nut shell liquid (CNSL), 4g of hexamethylenetetramine (H powder), and then add a certain amount of distilled water to make the mixed system react at 80-90°C for 1-3 hours, and then heat up to 130-140°C for reflux treatment for 1-2 hours to obtain cardanol-formaldehyde polycondensate (PCF);

[0027] 2) Use 0.8g p-toluenesulfonic acid as a catalyst, 1g 1,4-hydroquinone as a polymerization inhibitor, and 30g xylene as a solvent. After mixing, add 50g cardanol formaldehyde condensation polymer (PCF) and 50g acryloyl chloride (AC), then reflux at 80-90°C for 6 hours, then heat up to 100-110°C, and react again for 5-6 hours to obtain acryloyl chloride cardanol phenolic photosensitive resin (MPCF), that is, cardanol-based photocuring Prepolymer; Wherein, the viscosity of acryloyl chloride cardanol phenolic photose...

Embodiment 2

[0032] 1) Using xylene as solvent, add 100g of cashew nut shell liquid (CNSL), 4g of hexamethylenetetramine (H powder), and then add a certain amount of distilled water; make the mixed system react at 80-90°C for 1-3 hours, and then heat up to 130-140°C for reflux treatment for 1-2 hours to obtain cardanol-formaldehyde polycondensate (PCF);

[0033] 2) With 0.8g p-toluenesulfonic acid as catalyst, 1g 1,4-hydroquinone as polymerization inhibitor, and 30g xylene as solvent, after mixing, add 34g cardanol formaldehyde condensation polymer (PCF) and 66g methyl Acrylic acid (MAA), reflux at a temperature of 80-90°C for 6 hours, then raise the temperature to 100-110°C, and react for 5-6 hours to obtain a methacrylic cardanol phenolic photosensitive resin with a viscosity of 1352mPa·s;

[0034]3) after the solvent rotary evaporation in the methacrylic acid cardan phenolic photosensitive resin that step (2) makes, 50g methacrylic acid cardan phenolic photosensitive resin is added to 2...

Embodiment 3

[0038] 1) Using xylene as a solvent, add 100g of cashew nut shell liquid (CNSL), 4g of hexamethylenetetramine (H powder), and then add a certain amount of distilled water to make the mixed system react at 80-90°C for 1-3 hours , and then heat up to 130-140° C. for reflux treatment for 1-2 hours to obtain cardanol-formaldehyde polycondensate (PCF);

[0039] 2) take 0.8g p-toluenesulfonic acid as catalyst, 1g 1,4-hydroquinone as polymerization inhibitor, 30g xylene as solvent, after mixing, add 50g cardanol formaldehyde condensation polymer (PCF) and 50g acrylic acid ( AA), reflux at 80-90°C for 6 hours, then heat up to 100-110°C, and react for 5-6 hours to obtain an acrylic cashew phenolic photosensitive resin with a viscosity of 1710mPa·s;

[0040] 3) After the solvent in the acrylic cardanol phenolic photosensitive resin prepared by step (2) is rotated and evaporated, 50g of acrylic cardanol phenolic photosensitive resin is added to the 2,4,6-trimethylmethanol that is a photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com