Wide-body controllable feed device and feed method thereof

A feeding device and wide-body technology, which is applied in the field of wide-body controllable feeding devices, can solve the problems of equipment not working normally, materials not being transported stably, and materials not being transported stably, so as to solve the problem of material jamming and improve Overall controllability and stability, the effect of improving flow controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

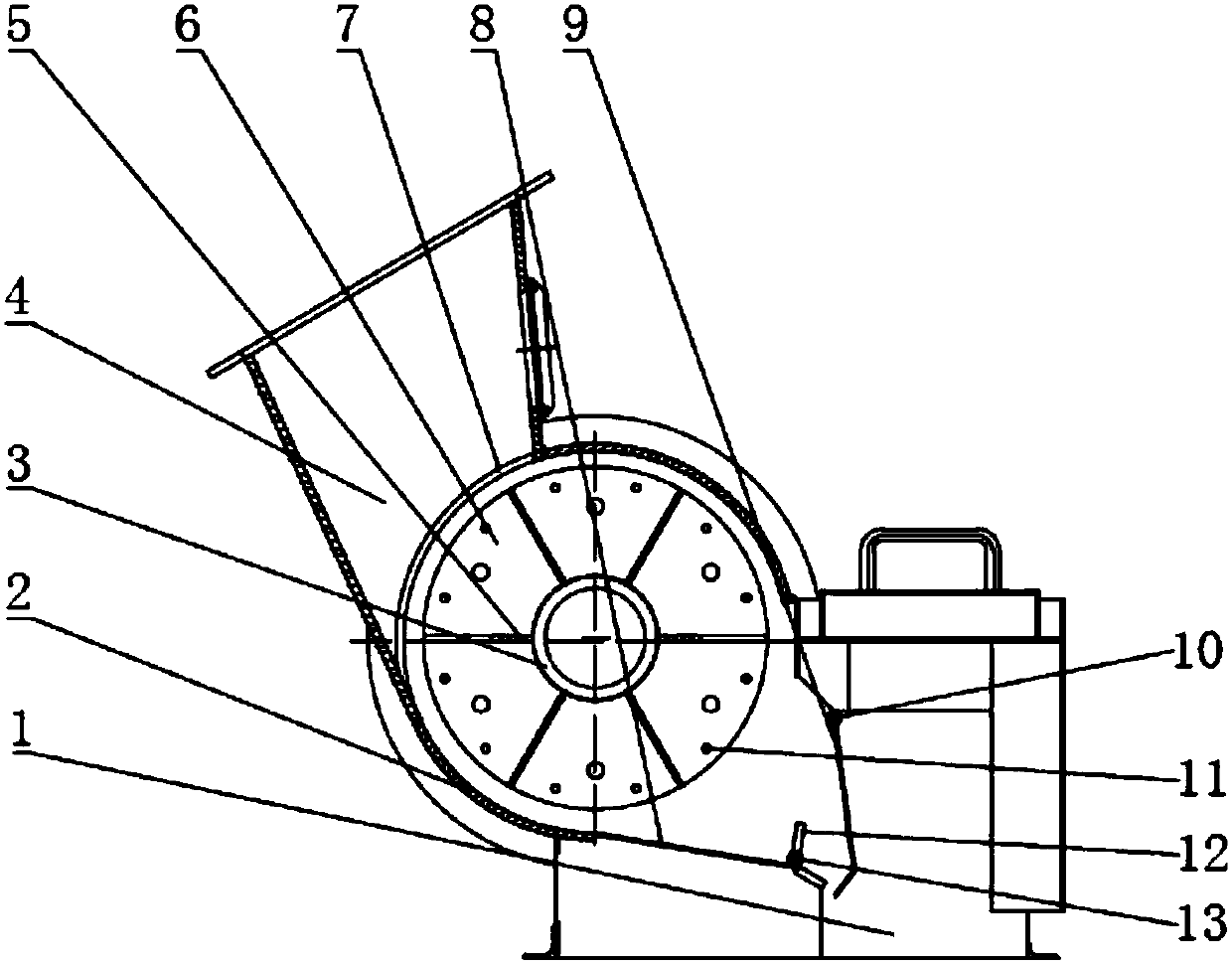

[0040] The invention provides a wide-body controllable feeding device and a feeding method thereof. Such as figure 1 and figure 2As shown, the wide-body controllable feeding device includes a feed channel 4, a discharge channel 1, an outer cylinder body 2 and a rotor assembly. The feed channel 4 and the discharge channel 1 are respectively located at the front upper part and the rear lower part of the outer cylinder 2 (front and rear are relative to the flow direction of the material), and the feed channel 4 and the outer cylinder 2 near the front upper part of the feed The mouth is connected. The discharge channel 1 is connected with the discharge port of the outer cylinder 2 near the lower part of the rear side thereof. The rotor assembly is located in the outer cylinder 2, and when the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com