Control method for capacitor voltage optimization and equalization of modular multilevel converter submodule

A modular multi-level, capacitor voltage technology, applied in the direction of AC power input conversion to AC power output, AC power input conversion to DC power output, electrical components, etc., can solve problems such as increasing switching loss, and reduce switching frequency. , Low transmission loss, reducing the effect of frequent switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the present invention in more detail, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

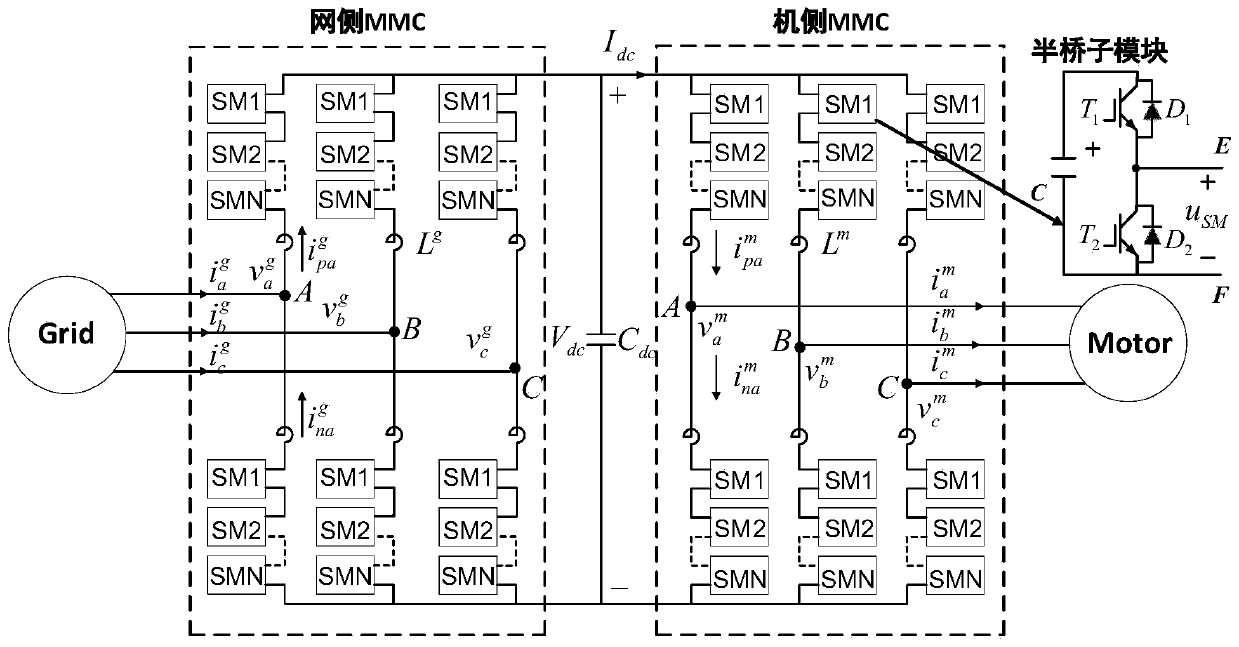

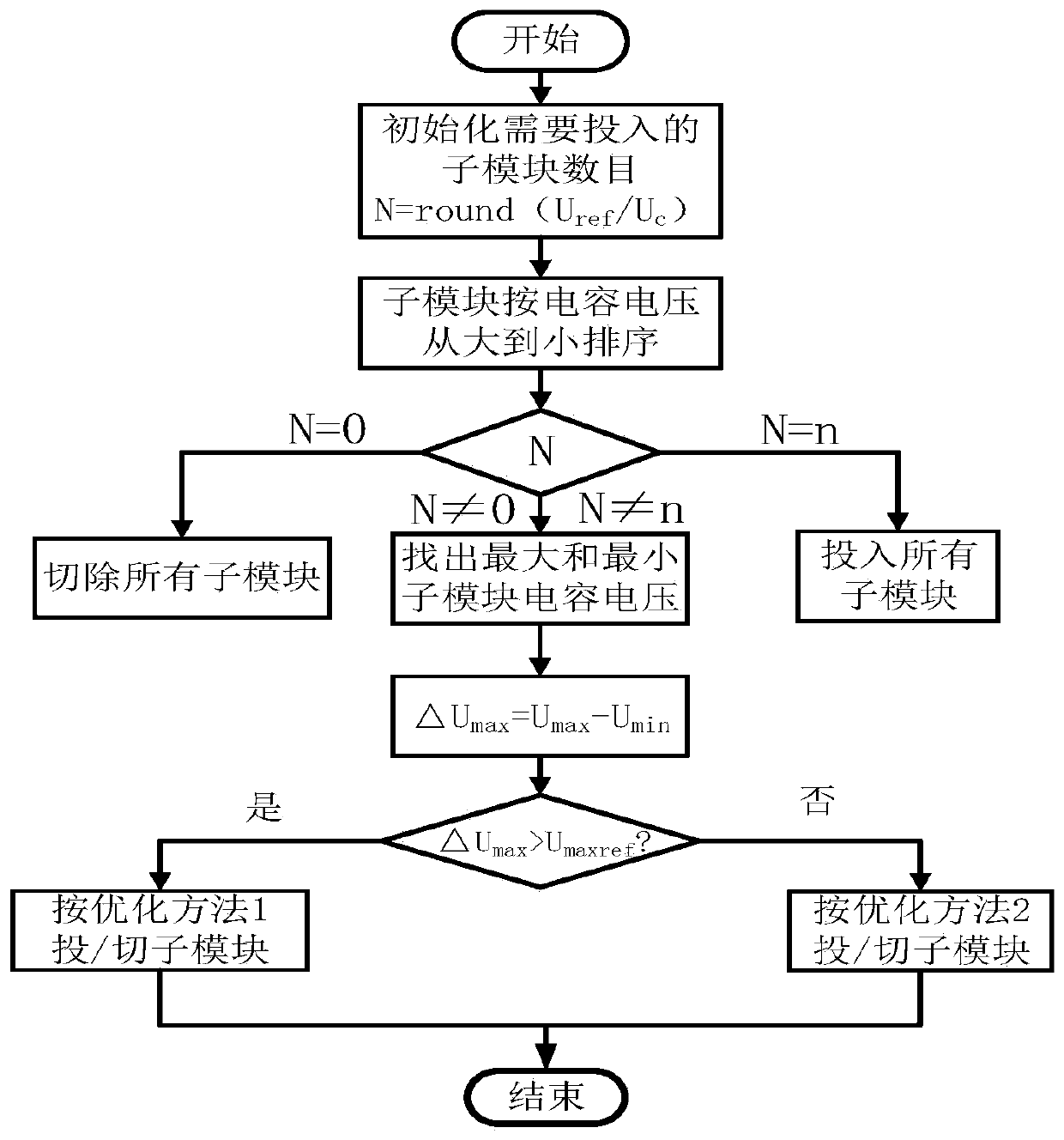

[0024] The present invention relates to a control method for optimizing and balancing the capacitor voltage of a modular multilevel converter sub-module, and the adopted MMC main circuit topology is as follows: figure 1 shown. The main circuit is composed of network-side MMC and machine-side MMC. Both sides are composed of three-phase six bridge arms. The sub-module of each bridge arm adopts a half-bridge structure. Each phase bridge arm consists of a commutation reactance and N half-bridges. The structure is composed of sub-modules, where each sub-module includes two IGBTs, an energy storage capacitor and a freewheeling diode. By controlling the on and off of the sub-modules, a stable waveform can be output at the output terminal.

[0025] Table 1 shows the working state and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com